Stator assembly and motor equipped with same, compressor, and refrigeration equipment

A component and stator technology, applied in the field of compressors, can solve the problems of small magnetic flux harmonics, multi-slot area of the main winding, large magnetic flux harmonics, etc., to reduce stray loss, balance heat loss, and magnetic flux harmonics Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

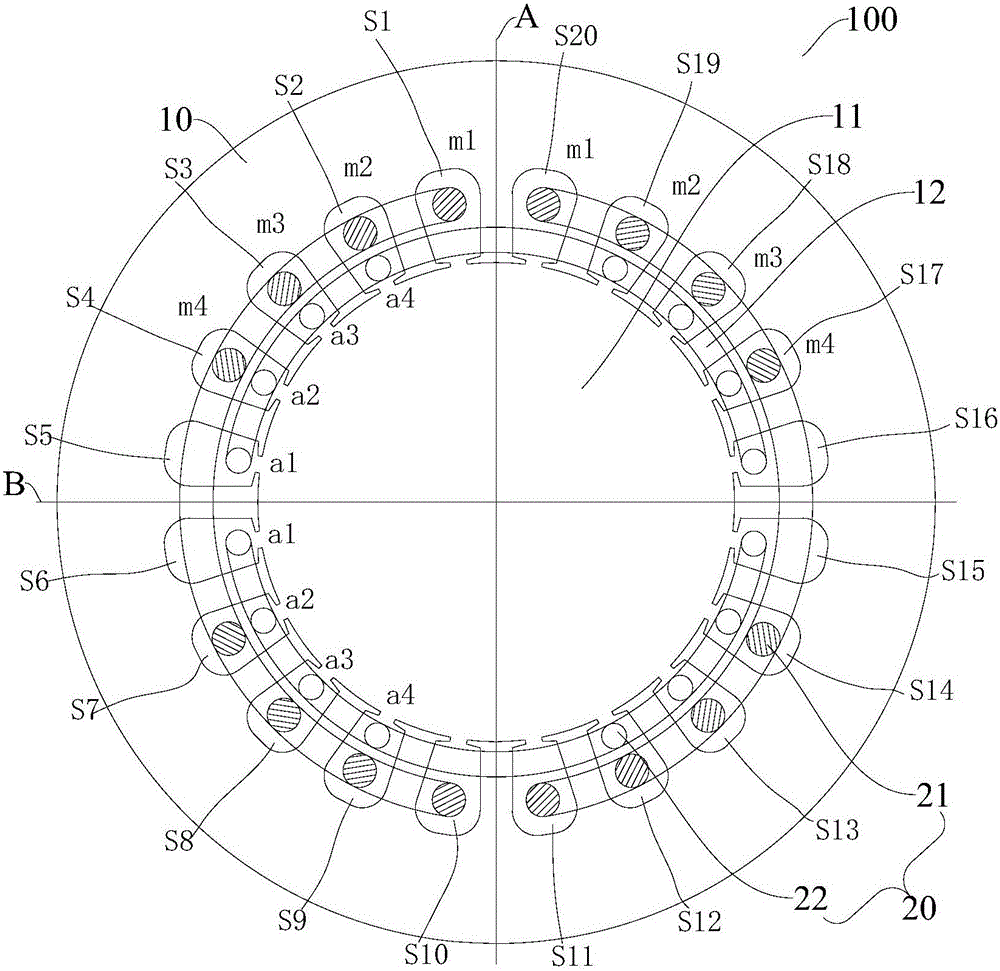

[0054] Such as figure 1 As shown, in this embodiment, the stator assembly 100 includes a stator iron and a stator winding 20 . Specifically, the stator core 10 has 20 stator teeth 12 arranged at intervals along its circumference, and stator slots are defined between adjacent two stator teeth 12 (such as figure 1 S1-S20 shown), the stator winding 20 includes a main winding 21 and an auxiliary winding 22, a plurality of coils of the main winding 21 and the auxiliary winding 22 are respectively wound in the stator slot in a concentric winding manner, and the main winding 21 and the auxiliary winding The winding 22 is distributed orthogonally on the stator core 10. In the same pole of the main winding 21, the number of stator slots occupied by the effective side of each coil is km, and the effective side of each coil is in The sum of the cross-sectional areas of the windings in the stator slots is Sm, and in the same pole of the secondary winding 22, the number of stator slots oc...

Embodiment 2

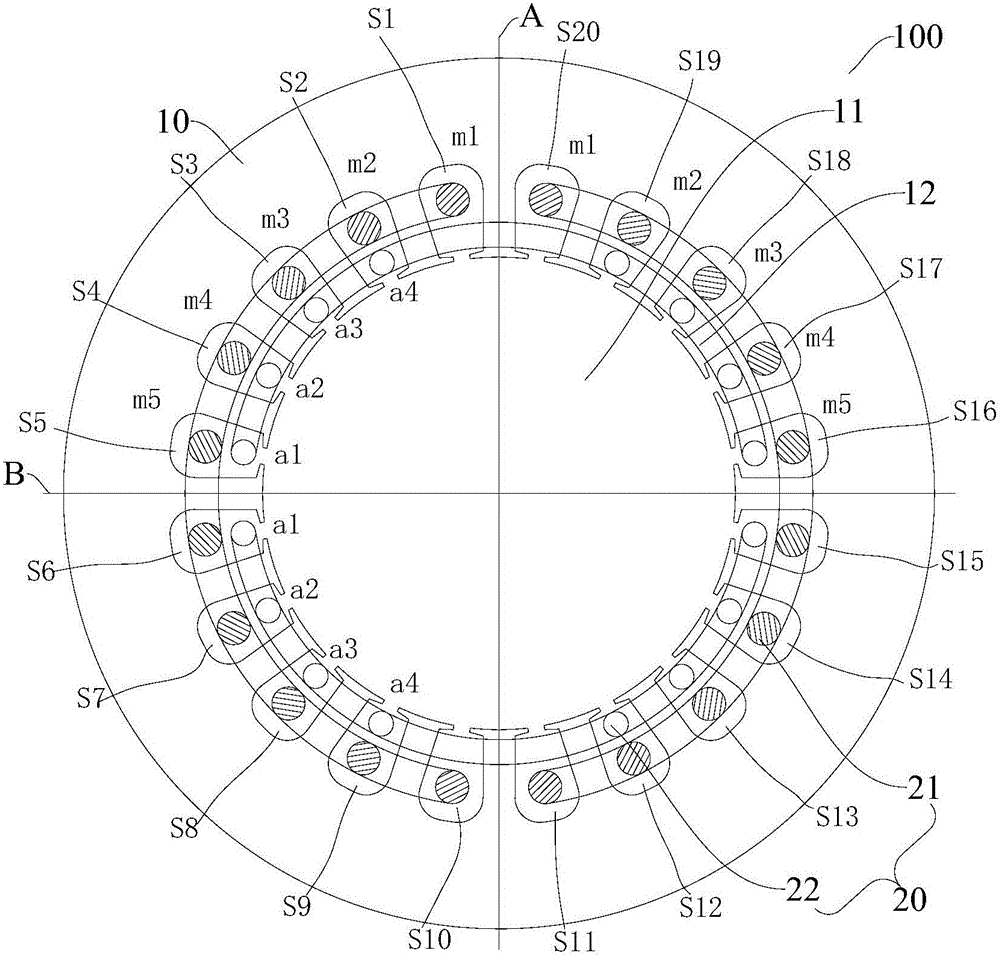

[0058] Such as figure 2 As shown, in this embodiment, the number of stator slots of the stator assembly 100 is 20, km is 5, and ka is 4. In the same pole of the main winding 21, the number km of stator slots occupied by the effective side of each coil is 5, and in the same pole of the secondary winding 22, the number of stator slots occupied by the effective side of each coil is The number ka of slots is 4, and the stator winding 20 of the stator assembly 100 is distributed in "5 / 4", that is, the number of layers km of one pole of the main winding 21 is 5 layers, and the number of layers ka of one pole of the auxiliary winding 22 is 4th floor.

[0059] By changing the "4 / 3" distribution of the stator windings in the related art to the "5 / 4" distribution of the stator windings 20, at the same time controlling the winding of the same side effective side of each coil of the main winding 21 in the stator slot The ratio of the sum Sm of wire cross-sectional areas to the winding ...

Embodiment 3

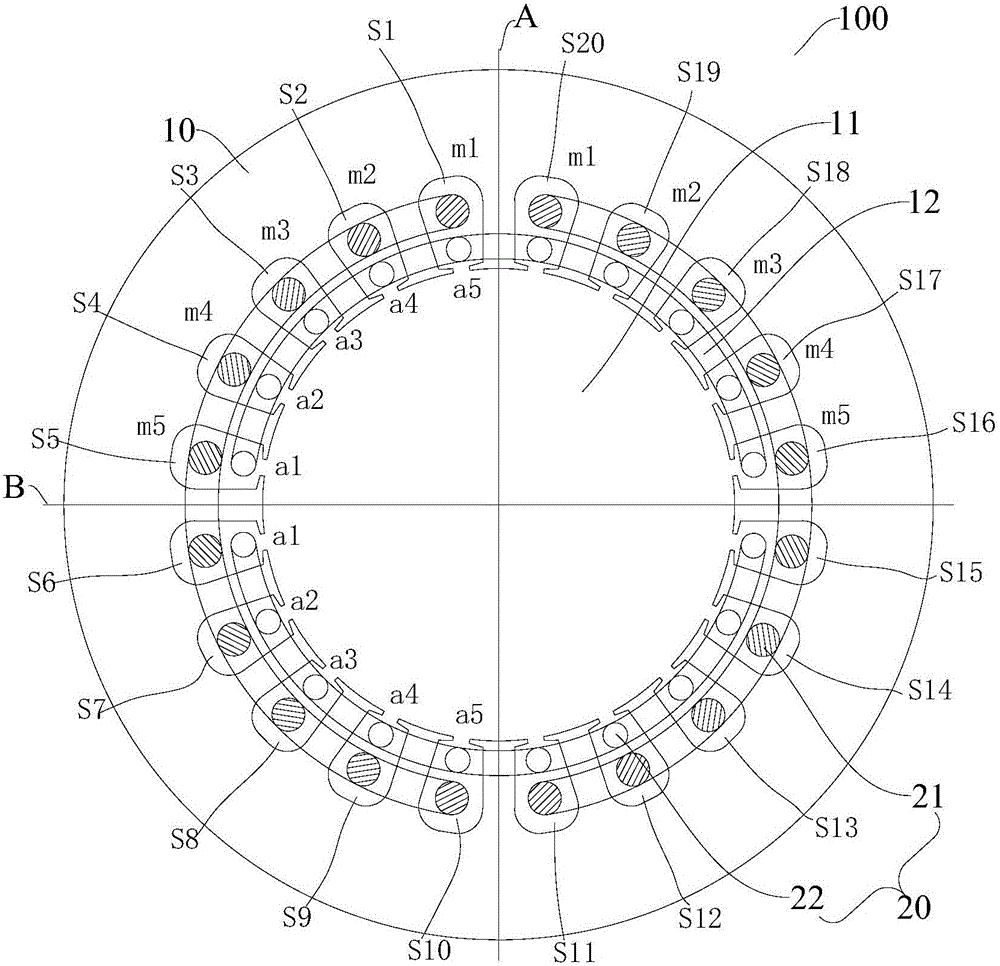

[0061] Such as image 3 As shown, in this embodiment, the number of stator slots of the stator winding 20 is 20, and km=ka=5. In the same pole of the main winding 21, the number km of stator slots occupied by the effective side of each coil is 5, and in the same pole of the secondary winding 22, the number of stator slots occupied by the effective side of each coil is The number ka of slots is 5, and the stator winding 20 of the stator assembly 100 is distributed in "5 / 5", that is, the number of layers km of one pole of the main winding 21 is 5 layers, and the number of layers ka of one pole of the auxiliary winding 22 is 5 layers, by changing the “4 / 3” distribution of the stator windings in the related art to the “5 / 5” distribution of the stator windings 20, and at the same time controlling the effective side of each coil of the main winding 21 in the stator slot The ratio of the sum of the winding cross-sectional areas Sm and the winding cross-sectional area Sa of the same-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com