Cereal grain drier

A grain granule and dryer technology, applied in the direction of storing seeds by drying, etc., can solve the problems of uneven drying, damaged grain granules, difficulty in drying grains, etc., and achieves good heat transfer effect, reduction of waste phenomenon, and heat absorption effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

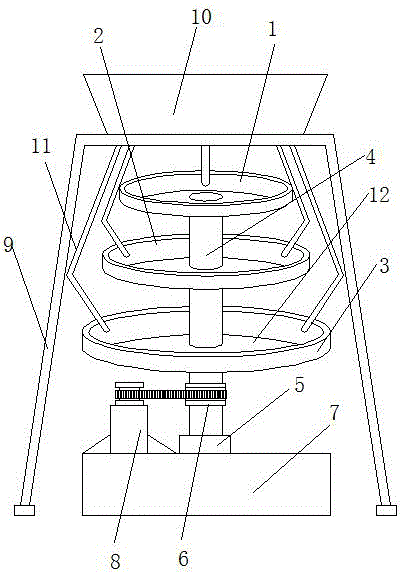

[0015] Refer to attached figure 1 The grain grain drier shown includes top tray 31, bottom tray and several middle trays 2 arranged between top tray 31 and the bottom tray, the top tray 31, some middle trays 2 and the bottom tray The inner diameter increases sequentially from top to bottom. The top tray 31, several middle trays 2 and the bottom tray are all made of graphite plates, and a layer of aluminum plate is arranged on the graphite plate, and the structure of the graphite plate and the aluminum plate is used to make the tray. In this way, the grain particles are placed on the aluminum plate of the holding tank 12, the heat of the sun is transferred through the aluminum plate, the graphite plate also has a bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com