An Efficient Vibration Swing Impact Nanomachine System

A nano-machine, high-efficiency technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., to achieve the effect of improved edible efficacy, convenient disassembly and cleaning, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

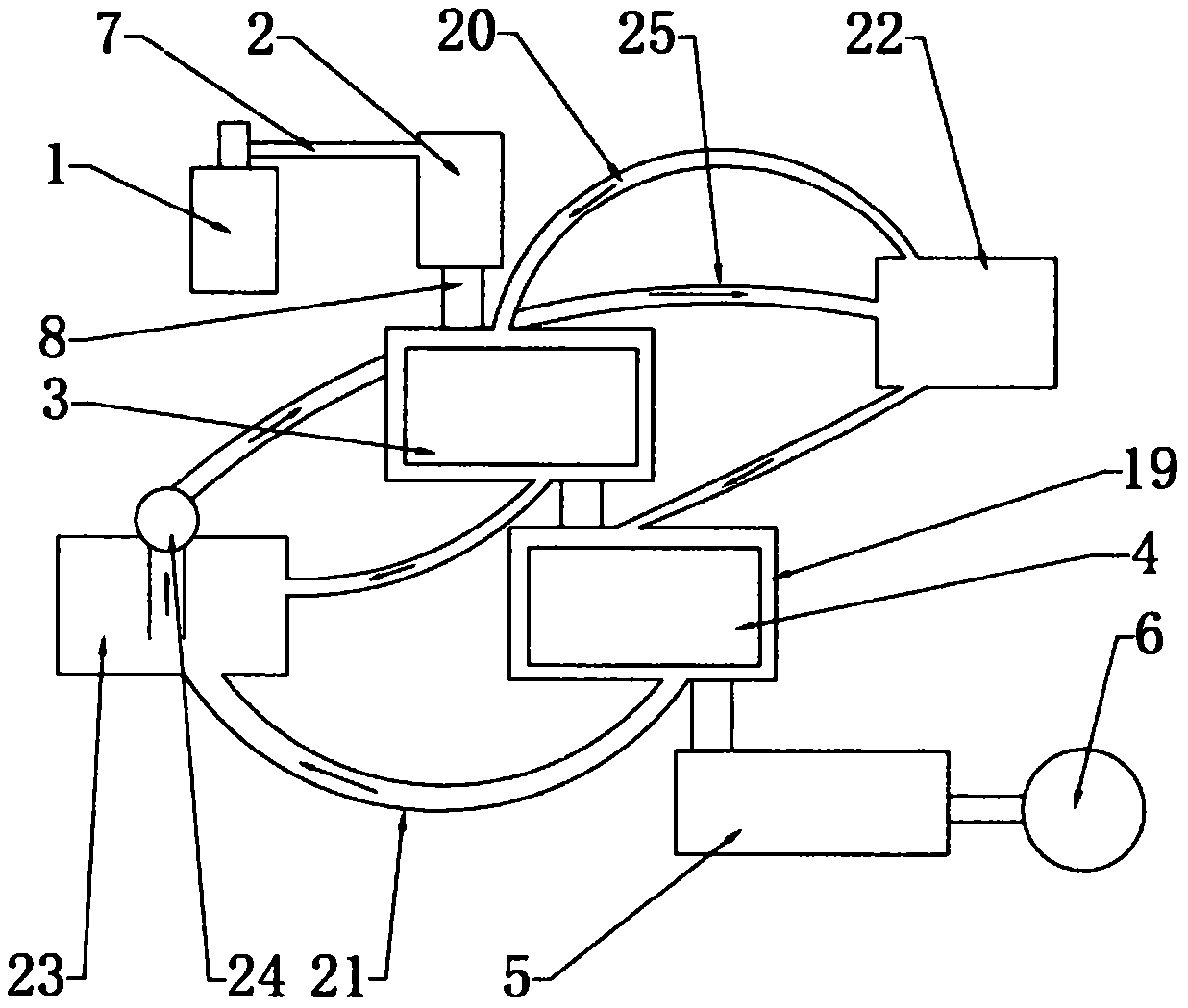

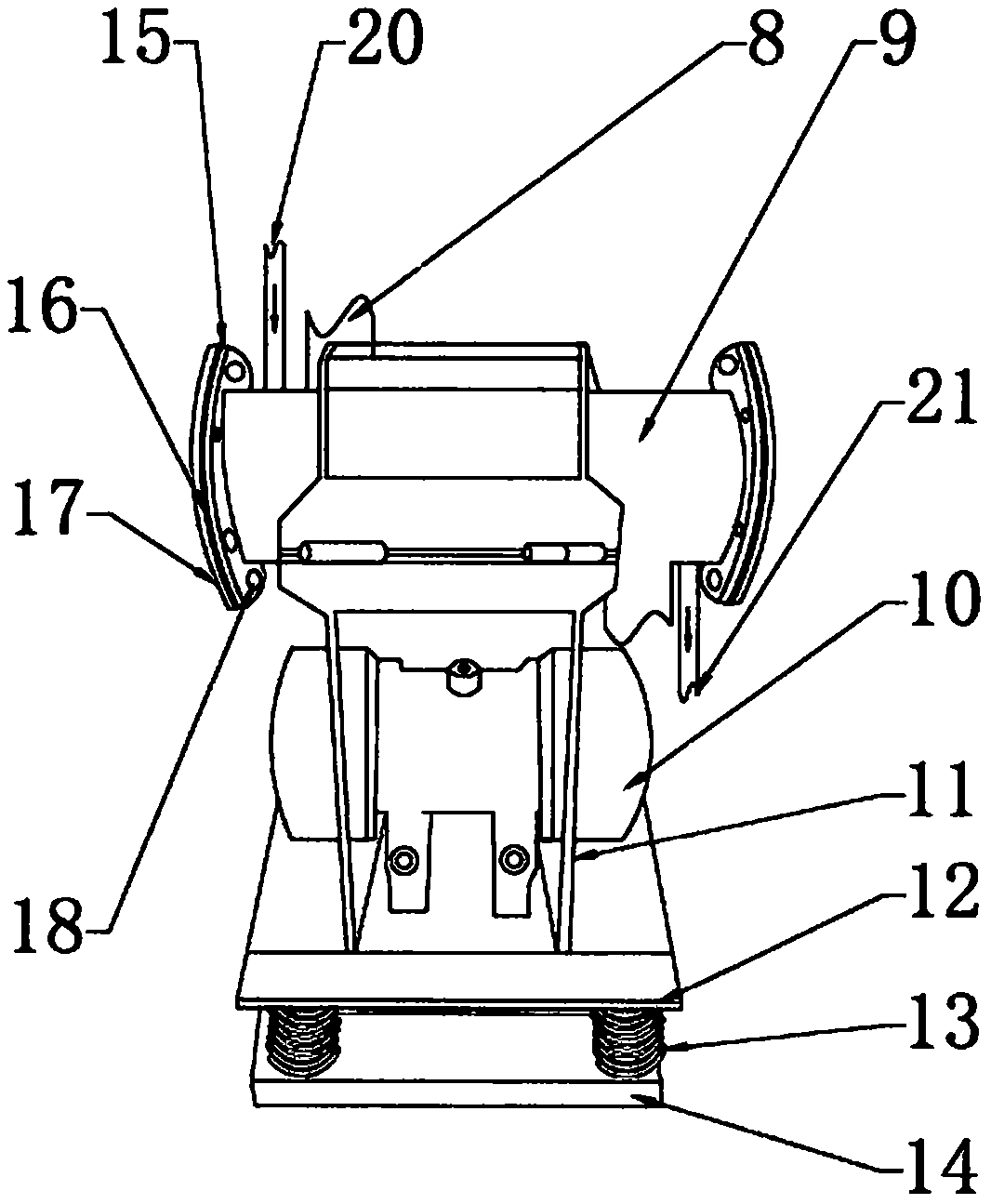

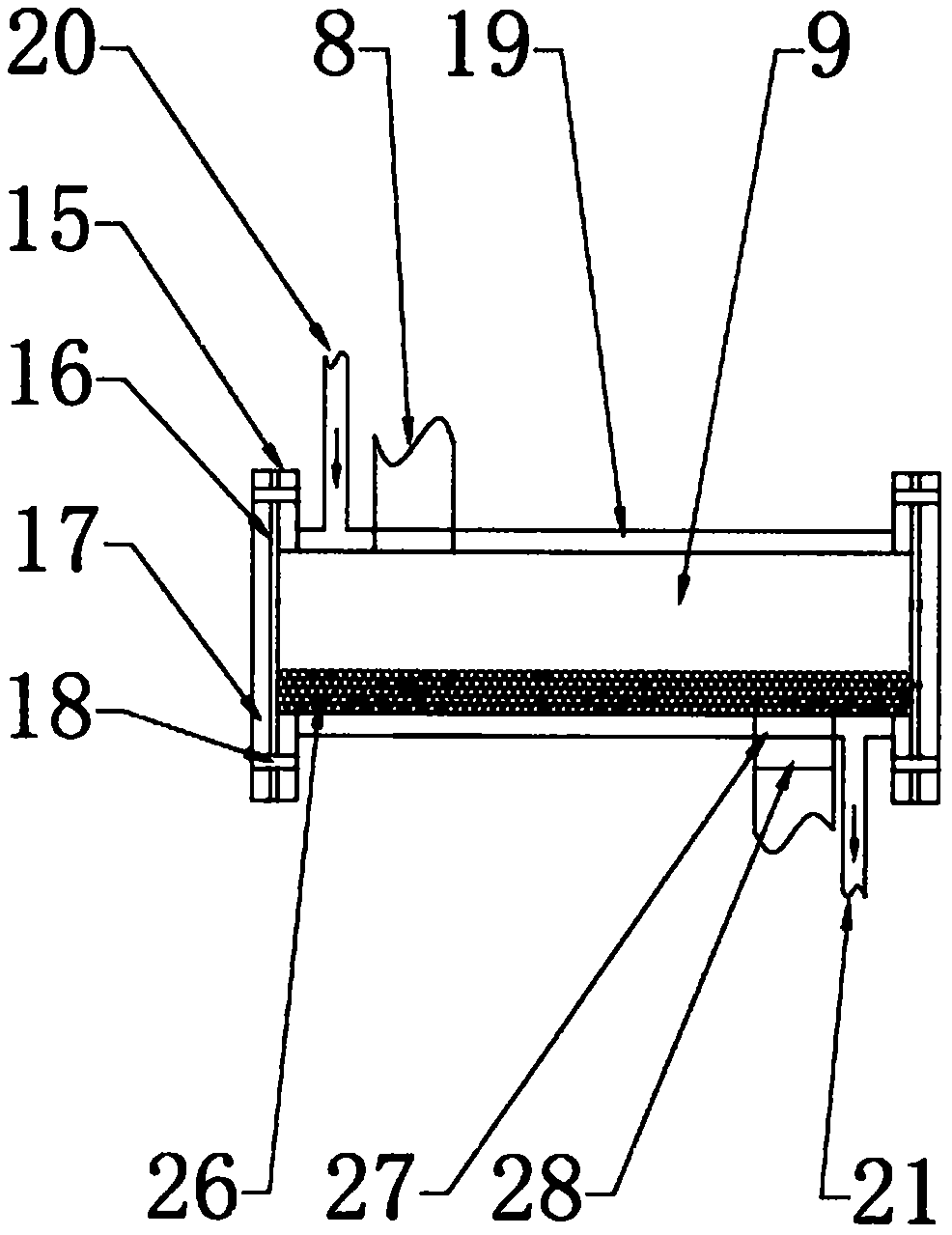

[0029] Attached below Figure 1-3 The present invention is described in further detail.

[0030] Such as figure 1 As shown, the nanomachine system includes a gas cylinder 1, a vacuum feeder 2, a first vacuum shock nanomachine 3, a second vacuum shock nanomachine 4, a vacuum packaging machine 5, a vacuum pump 6, the gas cylinder 1 and the vacuum feeder 2 are connected through the air pipe 7, the vacuum feeder 2, the first vacuum impact nano machine 3, the second vacuum impact nano machine 4, and the vacuum packaging machine 5 are connected successively through the feeding pipe 8, the vacuum packaging machine 5 and the vacuum pump 6 Connected through the gas pipeline 7, nitrogen is compressed in the gas cylinder 1. Such as Figure 2-3 As shown, the first vacuum shock nanomachine 3 and the second vacuum shock nanomachine 4 have the same internal structure, including a cavity 9, a vibration swing machine 10, four highly elastic springs 13 and a base 14. The cavity 9 contains i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com