Molten metal slag removing mechanical arm

A technology of manipulators and molten metal, applied in the direction of manipulators, mechanical cleaning, metal processing equipment, etc., can solve the problems of large volume of slag removal equipment, slag residue, high labor intensity, etc., to improve the uniformity and safety of adding, and reduce the volume And weight, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

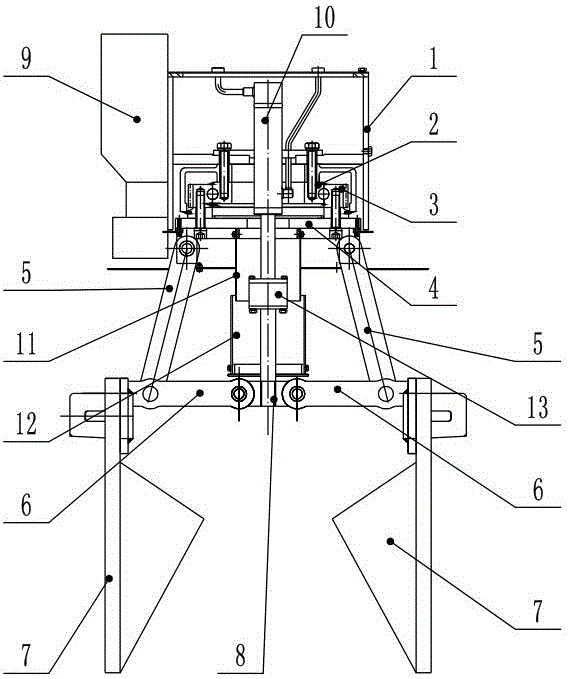

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0021] Such as figure 1 , a liquid metal slag removal manipulator, comprising a body 1 and a rotary drive assembly installed on the body 1;

[0022] The rotary drive assembly includes a rotary drive device, a fixed frame 2 mounted on the body 1 and a rotary part mounted on the fixed frame 2;

[0023] The rotary part includes a rotary ring gear 3 mounted on the fixed frame 2 through rollers to realize rotation relative to the fixed frame 2, and a rotary disc 4 installed at the bottom of the rotary ring gear 3; the rotary drive device is preferably hydraulic The motor, which can also be a motor, has gear teeth on the output shaft of the rotary drive device, and the gear teeth of the output shaft are meshed with the rotary ring gear 3 to drive the rotary ring gear 3 to rotate;

[0024] The rotary drive assembly is provided with a through hole through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com