A production method for progressive thickening of wood surface compression layer

A production method and compressed layer technology, applied in the direction of wood compression, wood treatment, wood treatment details, etc., can solve the problems of small controllable range of compressed layer thickness, small compressed layer thickness, low compressed layer density, etc., to avoid secondary The number of products, the improvement of elastic modulus, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

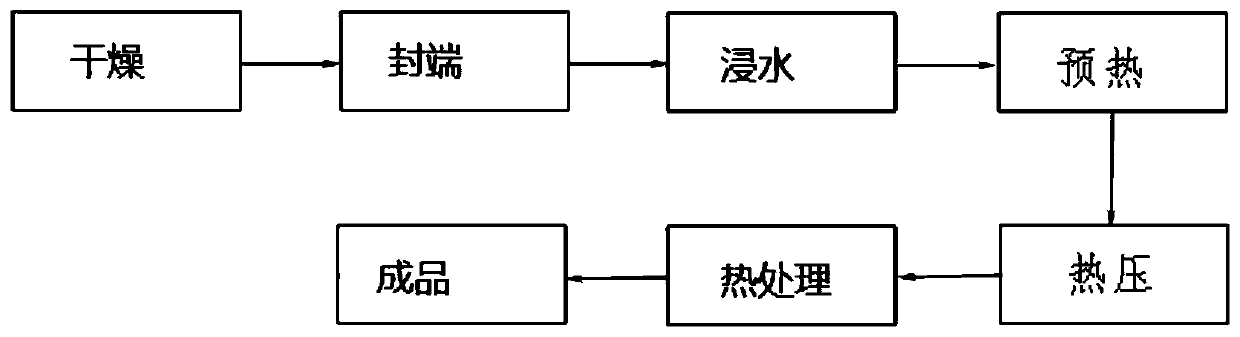

[0047] Embodiment 1: a kind of production method of wood surface compression layer progressively thickens, as attached image 3 As shown, it specifically includes the following steps:

[0048]a. Dry the board until the moisture content is below 12%;

[0049] b. Heating the solid paraffin with a melting point temperature in the range of 47°C-64°C, and then sealing the wood, it is easier to form a paraffin hydrophobic layer with good sealing performance at a higher temperature;

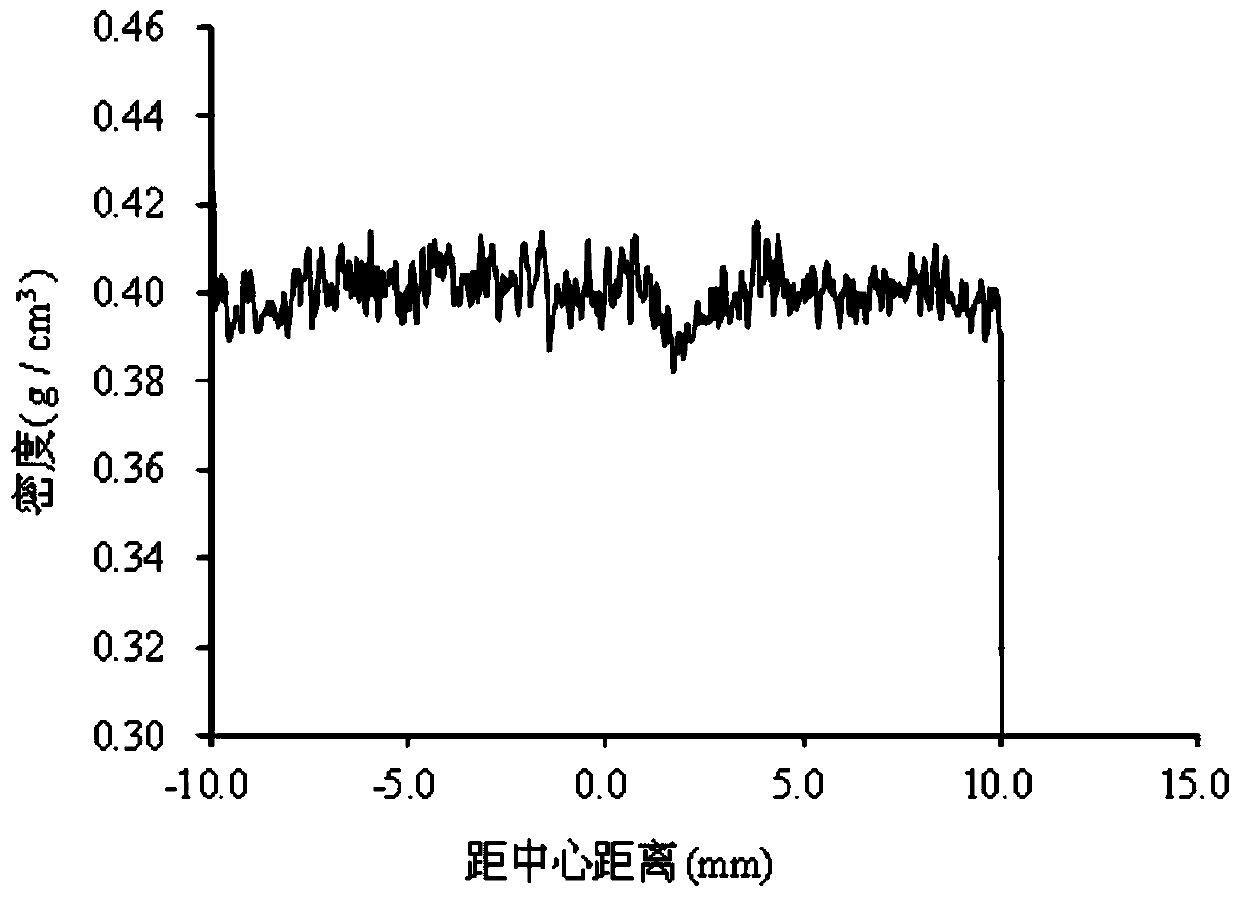

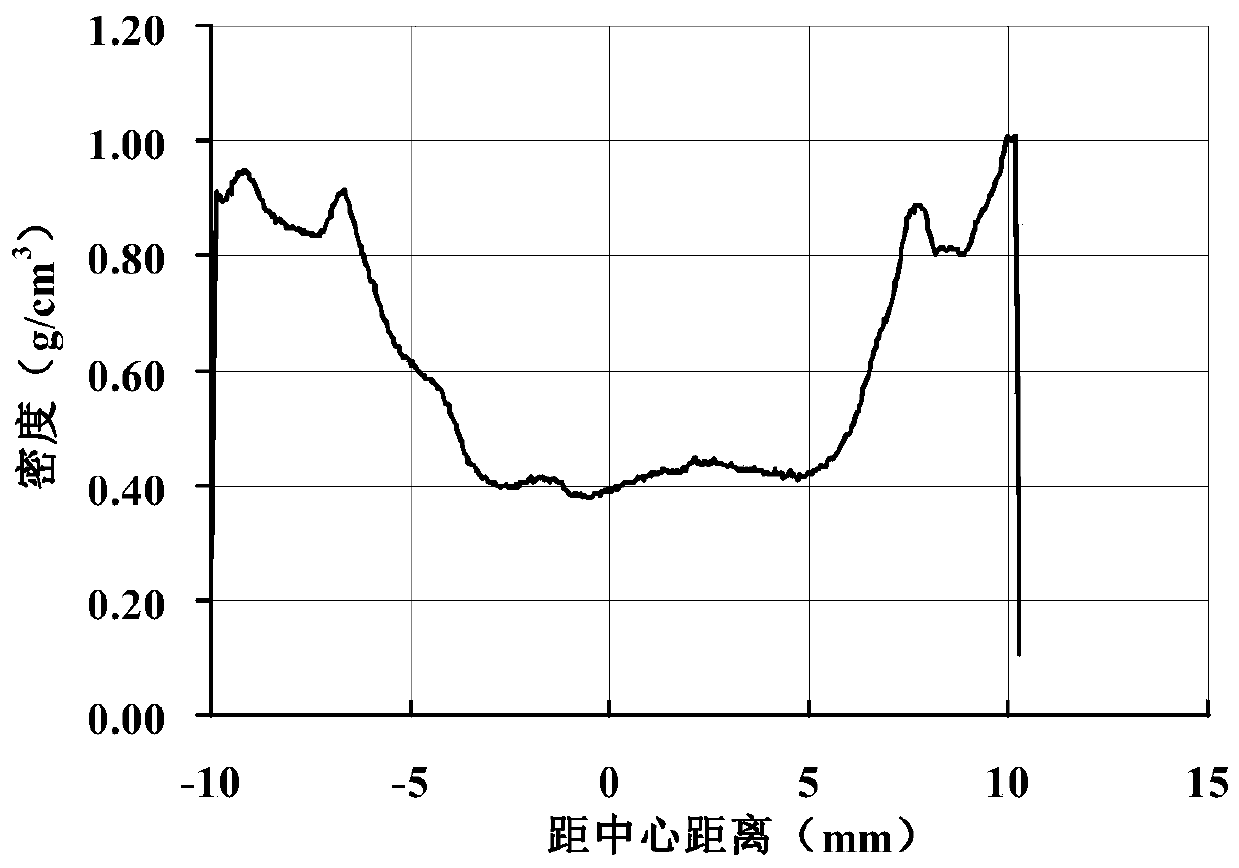

[0050] c. Carry out water immersion treatment on the board, and the immersion time is determined according to the compression thickness and water immersion coefficient, for example, the density is 0.40g / cm 3 Poplar, when compressed at 180°C, see the water immersion coefficient of compression amount and immersion time Figure 4 , if it is to be compressed into a surface layer of 12.5mm, the soaking time is 4h;

[0051] d. After soaking in water, the wood is clamped by a steel plate with a flat surface...

Embodiment 2

[0055] Embodiment 2: as attached Figure 5 As shown, the heat treatment process of the above-mentioned compressed surface layer:

[0056] (1) Within 10 to 20 minutes, the temperature is uniformly raised from room temperature to 90-110°C, and the oxygen content is uniformly reduced from 20-25% to 13-16%;

[0057] (2) From 10-20min to 75-85min, the temperature is evenly raised from 90-110°C to 120-130°C, and the oxygen content is evenly reduced from 13-16% to 9-11%;

[0058] (3) From 75-80min to 88-92min, the temperature is evenly raised from 120-130°C to 150-160°C, and the oxygen content is reduced from 9-11% to 2-3%;

[0059] (4) From 88-92min to 105-110min, the temperature is evenly raised from 150-160°C to 190-205°C, the oxygen content is maintained at 2-3%, and the oxygen content is maintained at 2-3%;

[0060] (5) From 105-110min to 220-230min, keep the temperature at 190-205°C and keep the oxygen content at 2-3%;

[0061] (6) From 220-230min to 265-272min, uniformly co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com