Fast paper box fetching mechanism for ceramic tile packaging line

A packaging line and carton technology, applied in the field of quick carton removal mechanism, can solve the problems affecting the packaging effect and speed of the whole machine, and the difficulty of fast and high-precision positioning of three-phase asynchronous motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with above-mentioned accompanying drawing, and its preferred specific implementation mode is:

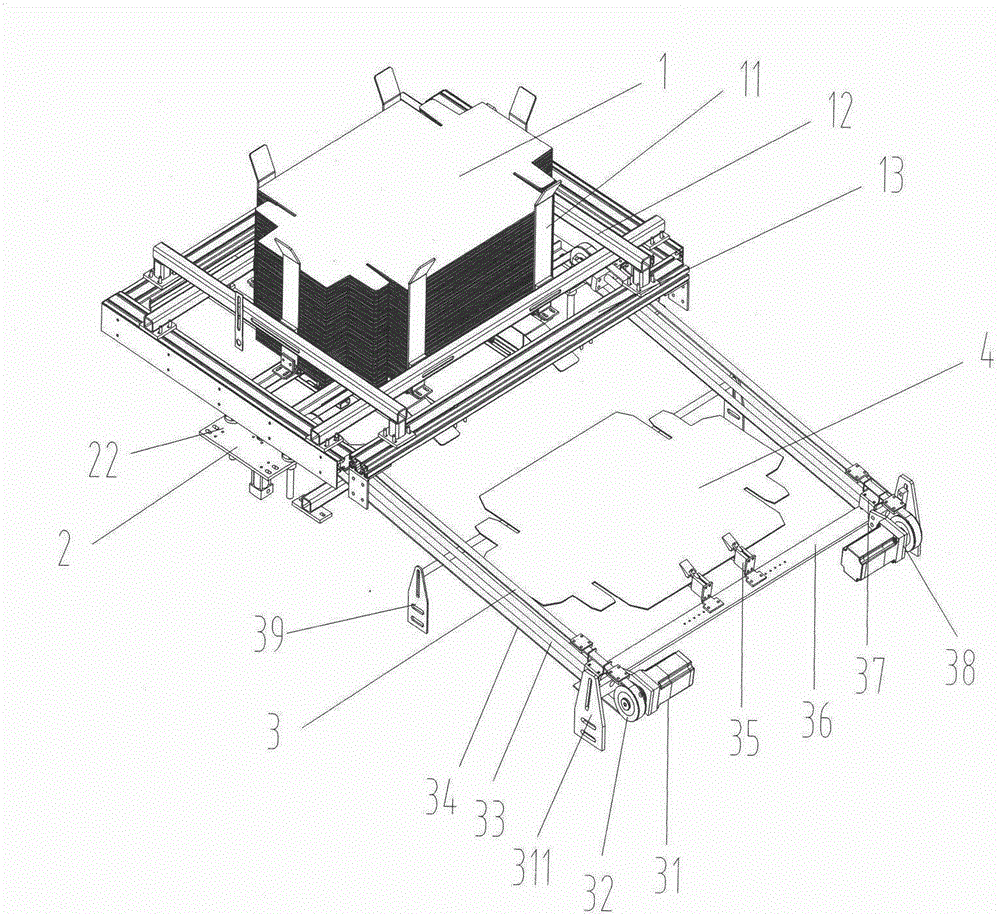

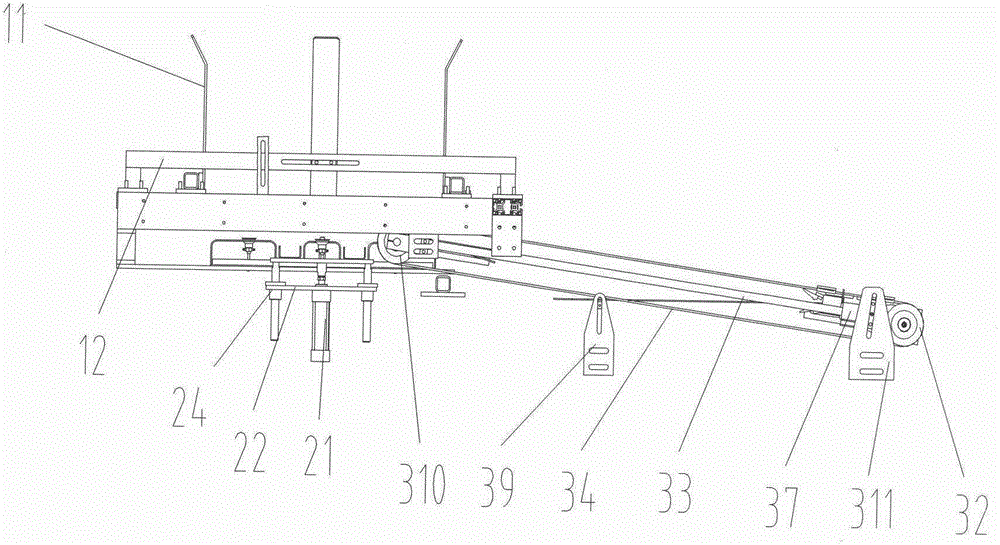

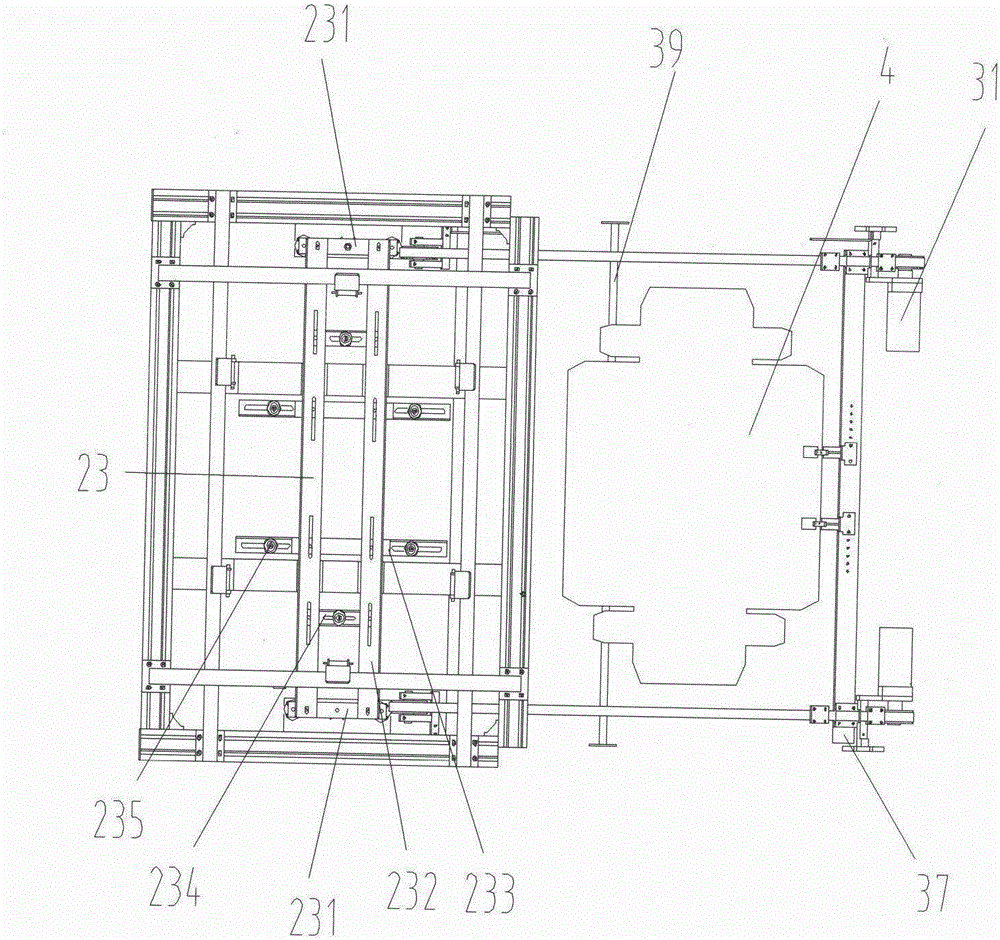

[0015] The present invention is a quick carton taking mechanism for ceramic tile packaging line. The mechanism is composed of a carton bin assembly 1, a suction carton assembly 2, and a paper clamping assembly 3, wherein the carton bin assembly 1 is installed on the upper part of the frame , located directly above the conveying line, the suction carton assembly 2 is located in the middle of the carton warehouse assembly 1 and the conveying line and connected to the frame, and the clamping paper assembly 3 is located directly above the conveying line and obliquely behind the carton warehouse assembly 1 Tilt back and down to connect with the rack.

[0016] Further, the four aluminum profiles 13 in the carton warehouse assembly 1 form a square frame and are fixed on the frame, and the four square tubes 12 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com