Full-automatic ampoule bottle production system and method

A production system and ampoule technology, which is applied in the direction of automatic packaging control, packaging bottles, packaging items, etc., can solve the problems of inconvenient production work and the inability to meet the needs of ampoule production and packing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 A fully automatic ampoule production system and method

[0065] The present invention takes ampoule bottle body production and testing equipment as the main body, and is combined with an automatic tube loading machine and boxing equipment to form a fully automated ampoule bottle production system. The supporting application of production and testing equipment constitutes a fully automated production line for tube feeding, bottle body processing, quality inspection, and qualified product packing, forming a complete ampoule bottle production system and method.

[0066] The automatic ampoule bottle production system includes the automatic tube loading machine, the ampoule bottle body production and testing equipment and packing equipment, all of which are controlled by the controller, the material tube output port of the automatic tube loading machine and the ampoule bottle body production and testing equipment The input port of the material tube corresponds to t...

Embodiment 2

[0077] Embodiment 2 A tube transfer mechanism and transfer method of an automatic tube loading machine

[0078] This embodiment is an improvement to the material tube transfer mechanism of the original automatic tube loading machine, that is, a material tube clamp is added on the suction cup assembly. When the transfer component transfers the material tube absorbed by the suction cup component, the adsorption force of the suction nozzle to the material tube and the clamping force of the material tube clamp to the material tube work together to avoid shaking in the material tube during the process of transferring the material tube. The material tube is stably adsorbed on the suction nozzle to improve the stability and reliability of transfer.

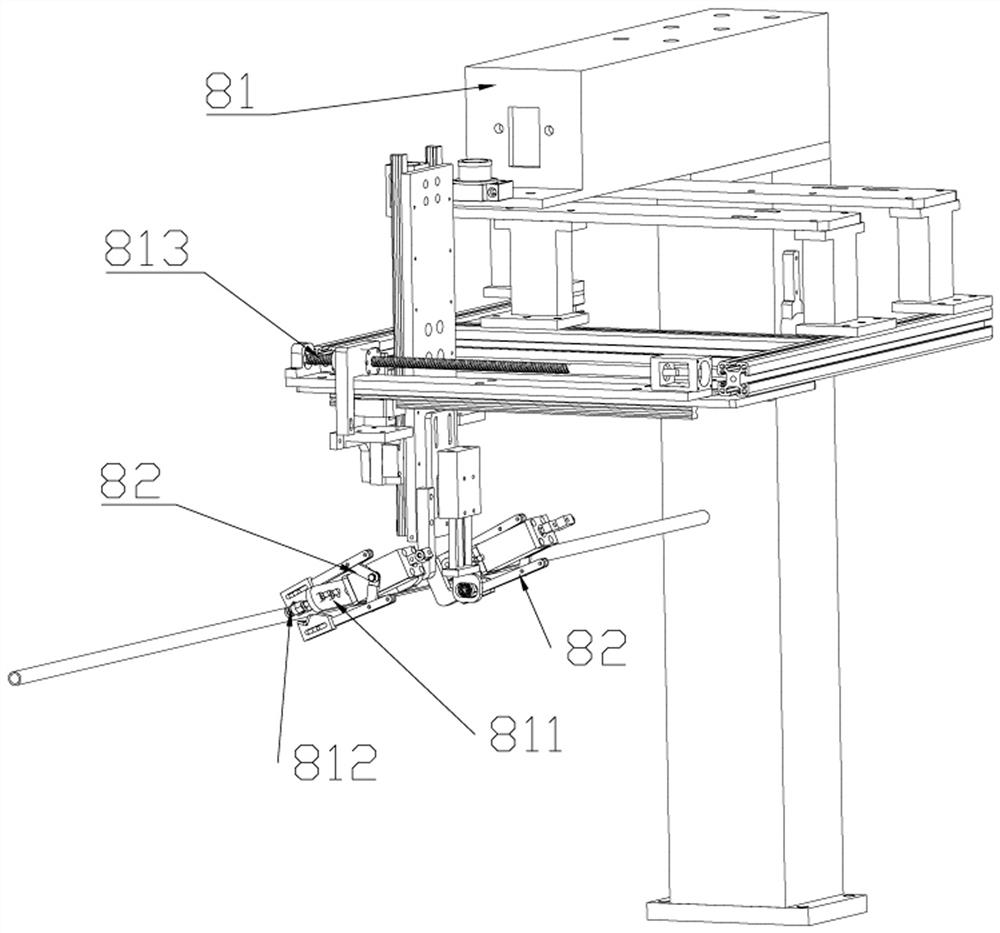

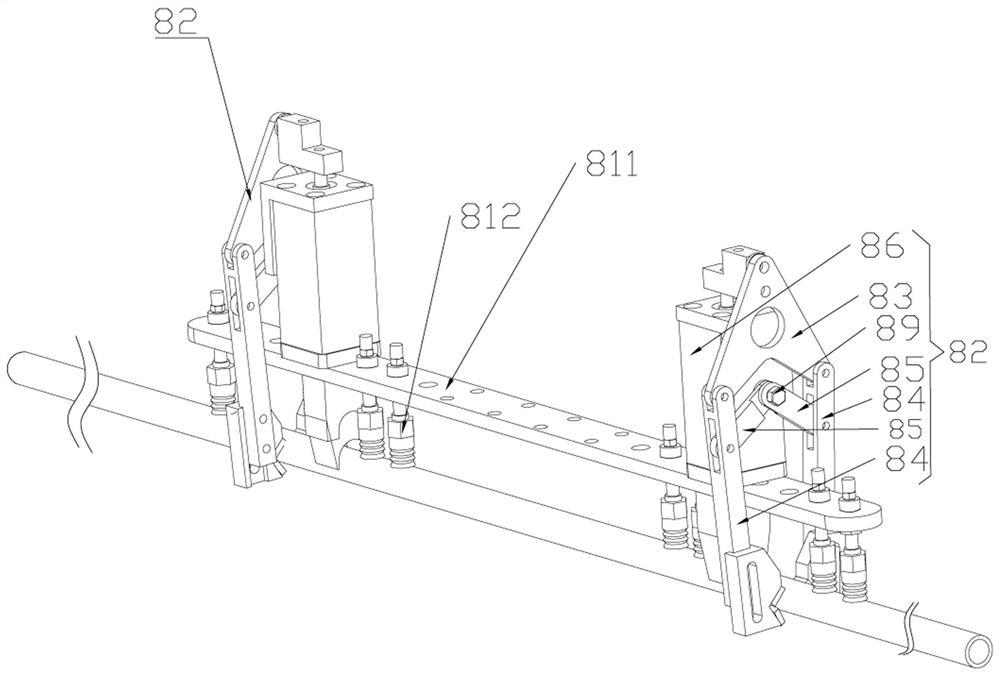

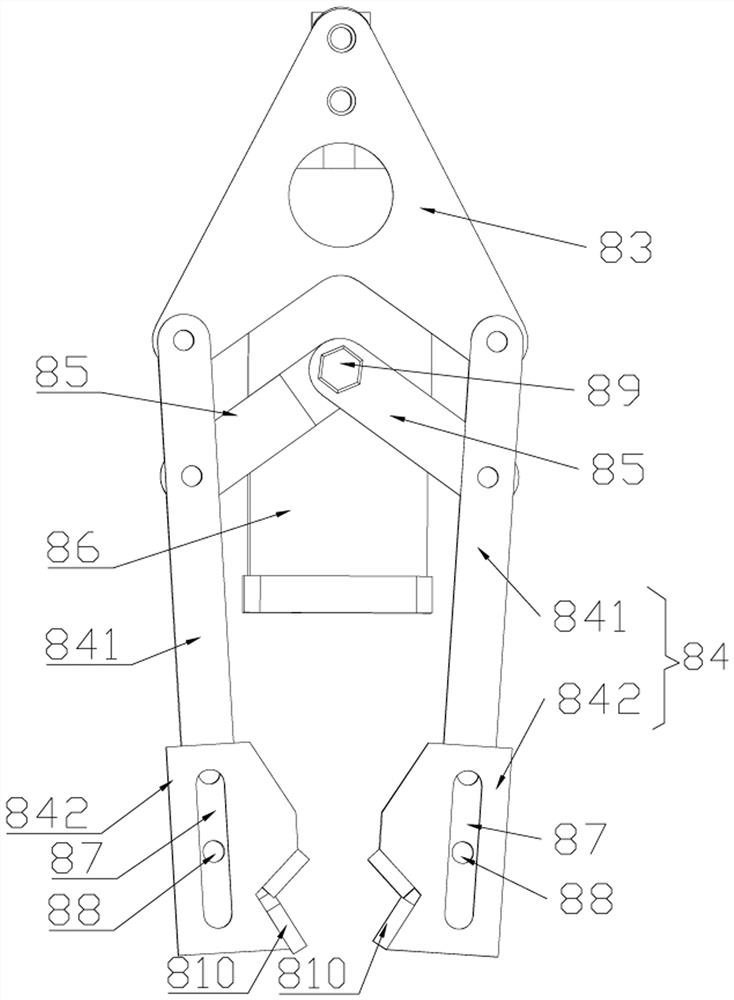

[0079] like Figure 1 to Figure 4 As shown, this embodiment includes a frame 81, a transfer assembly 813 assembled on the frame 81 for transferring the material pipe, a suction cup assembly assembled on the power output control end of t...

Embodiment 3

[0090] Example 3 A transfer intubation mechanism and transfer intubation method of an automatic tube loading machine

[0091] This embodiment improves the transfer intubation mechanism and transfer intubation method of the original automatic tube loading machine. The transfer and intubation working mode of the dynamic material tube input point on the chuck plate of the continuously running ampoule bottle body production and testing equipment changes the transfer trajectory and running speed of the transfer intubation mechanism, making the transfer track and running speed of the material tube It matches the running trajectory and running speed of the chuck plate of the ampoule bottle body production and testing equipment, and meets the needs of the tube loading of the ampoule bottle body production and testing equipment.

[0092] This embodiment includes a bracket, a transfer assembly assembled on the bracket, and an introducer assembled at the power output end of the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com