Terraced field automatic production robot

An automatic production and robot technology, applied in agricultural machinery and implements, agricultural gas emission reduction, agriculture, etc., can solve the problems of single function and difficult to meet the needs of automatic agricultural production, and achieve the effect of various functions and meet the needs of automatic production of terraced fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

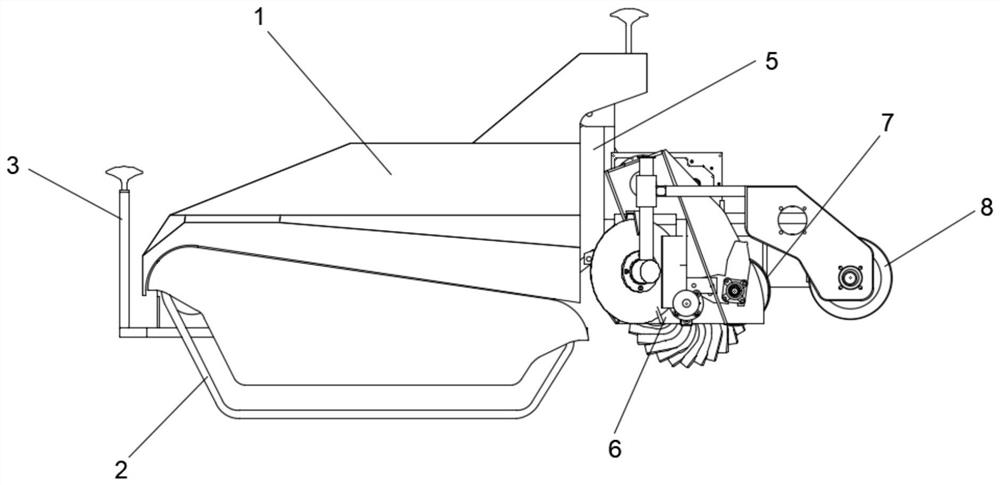

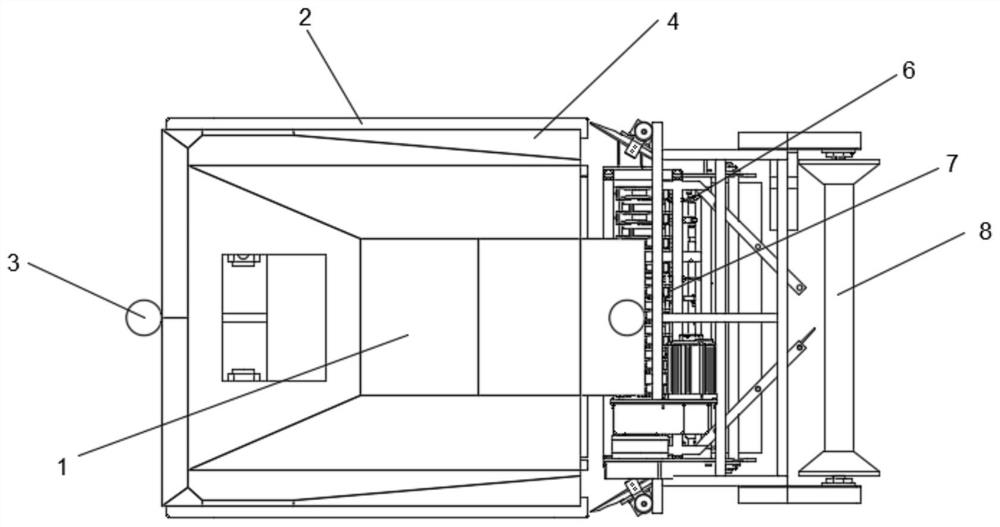

[0035] Example one, by Figure 1-13 Given, an automatic production robot for terraced fields includes a casing 1, a crawler wheel 2, an RTK antenna 3, a lidar 4, a three-point rear suspension assembly 5, a rotary tillage assembly 6, a seeding assembly 7 and a furrowing assembly 8, The track wheels 2 are installed on the left and right sides of the casing 1, the RTK antenna 3 is installed on the front side and the top of the casing 1, the lidar 4 is installed on the left and right sides of the top of the casing 1, and the three-point rear suspension assembly is installed inside the casing 1 5. The rotary tillage assembly 6, the seeding assembly 7 and the furrowing assembly 8 are all connected to the housing 1 through a three-point rear suspension assembly 5. The three-point rear suspension assembly 5 includes an upper bracket 501, a gantry frame 502, a lower bracket 503, The electric cylinder 504, the longitudinal beam 505 and the cylindrical pin 506, the gantry 502 and the low...

Embodiment 2

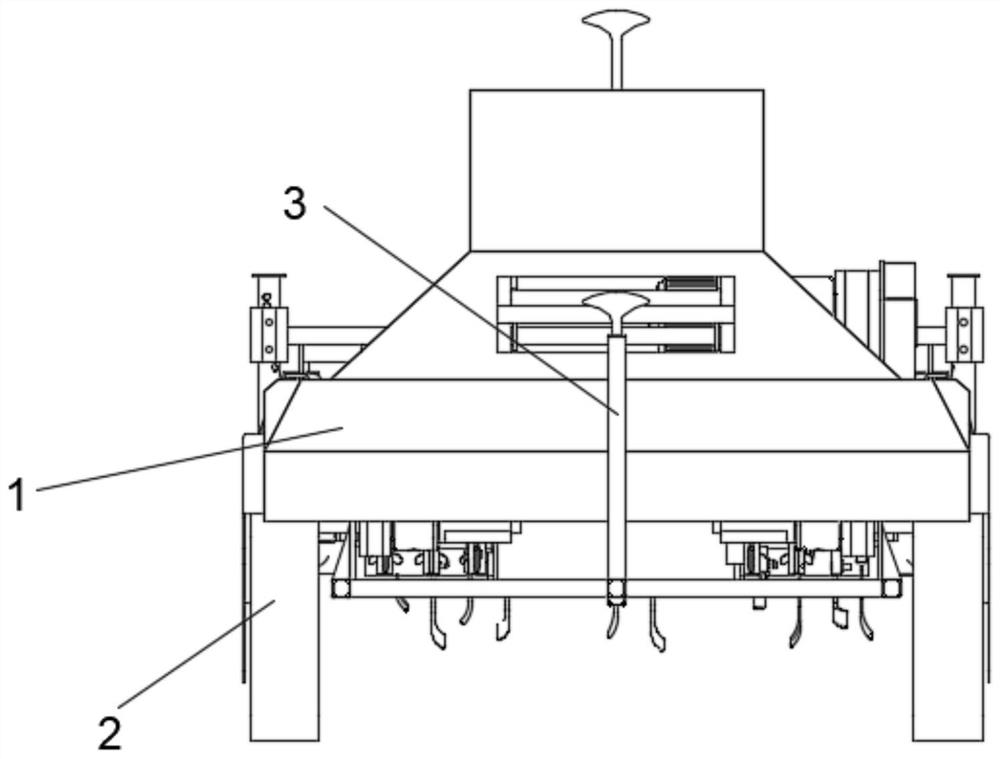

[0036] Embodiment 2, on the basis of Embodiment 1, the rotary tiller assembly 6 includes a rotary tiller frame 601, a left side plate 602, a right side plate 603, a knife shaft 604, a right-handed knife 605, a left-handed knife 606, a DC brushless The motor 607 and the driven double-row sprocket 609, the rotary tiller frame 601 is fixedly installed on the three-point rear suspension assembly 5, the left side plate 602 is mounted on the left side of the lower part of the rotary tiller frame 601, and the right side plate 603 is mounted on the rotary tiller. On the right side of the lower part of the frame 601, a cutter shaft 604 is rotatably installed inside the rotary tiller frame 601, a plurality of right-handed knives 605 and left-handed knives 606 are installed on the cutter shaft 604 at equal intervals, and one side of the right side plate 603 is installed with DC The brush motor 607 has an installation cavity inside the right side plate 603, the driven double-row sprocket 6...

Embodiment 3

[0037] Embodiment 3, on the basis of Embodiment 1, the seeding assembly 7 includes a seeding hanger 701, a seeding drive motor 702, a seeder assembly 703 and a pressing wheel assembly 704. The seeding hanger 701 is fixedly installed on the three-point rear suspension assembly. In step 5, a seeding drive motor 702 is installed on the lower left side of the seeding hanger 701, the seeder assembly 703 is installed inside the seeding hanger 701, the driving end of the seeding drive motor 702 is connected with the left end of the seeder assembly 703, and the pressing wheel assembly 704 is rotatably installed on the rear side of the seeding hanger 701, so that the robot has the function of seeding, and can automatically complete the seeding according to the task information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com