A fully automatic valve release machine without liquid pipe

A fully automatic technology without a suction pipe, applied in mechanical equipment, container discharge methods, gas/liquid distribution and storage, etc., can solve the problem that rubber gaskets are easy to drop and cannot meet the production and processing of special refrigerant aerosol for automobile air conditioners needs, losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

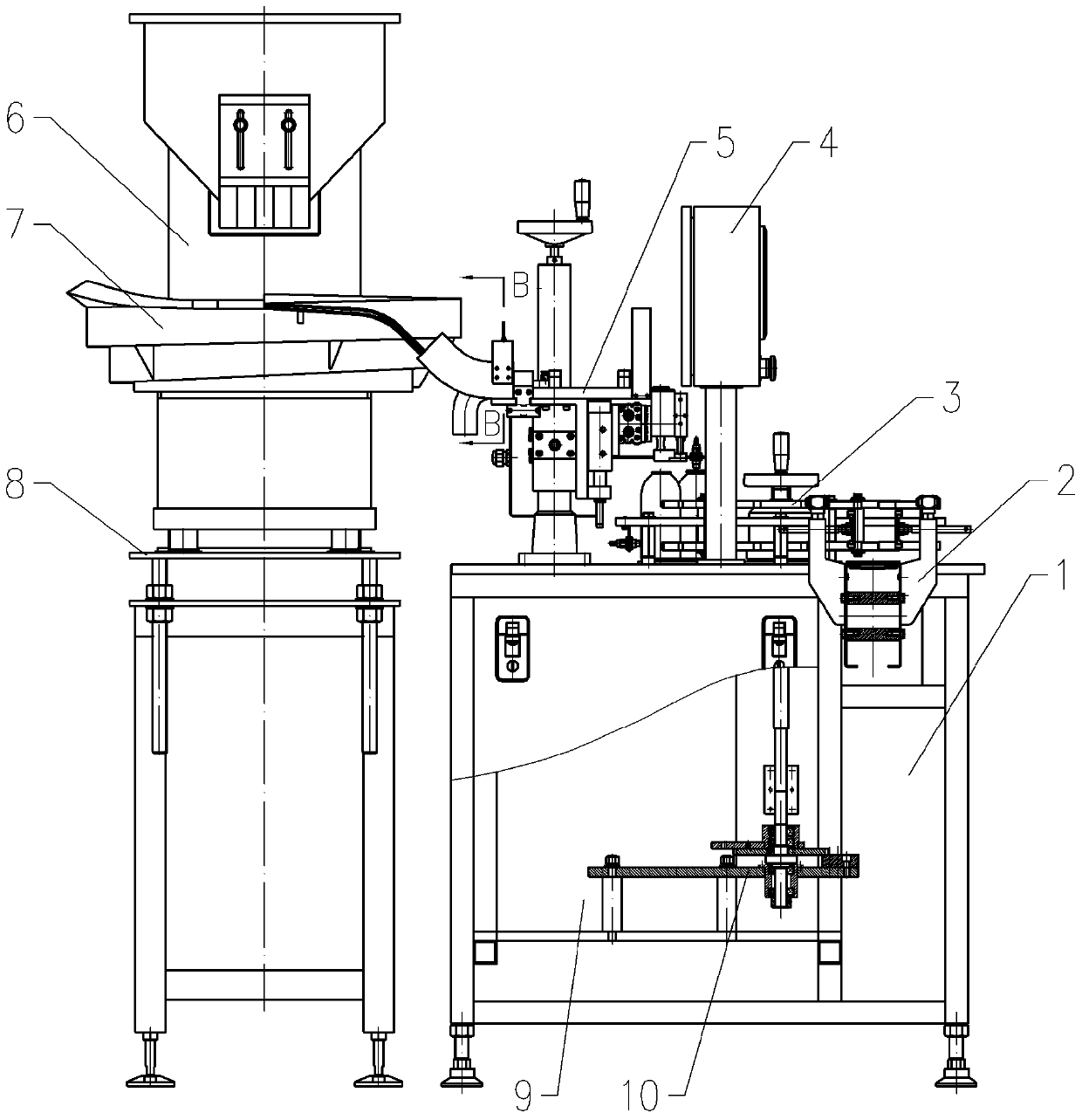

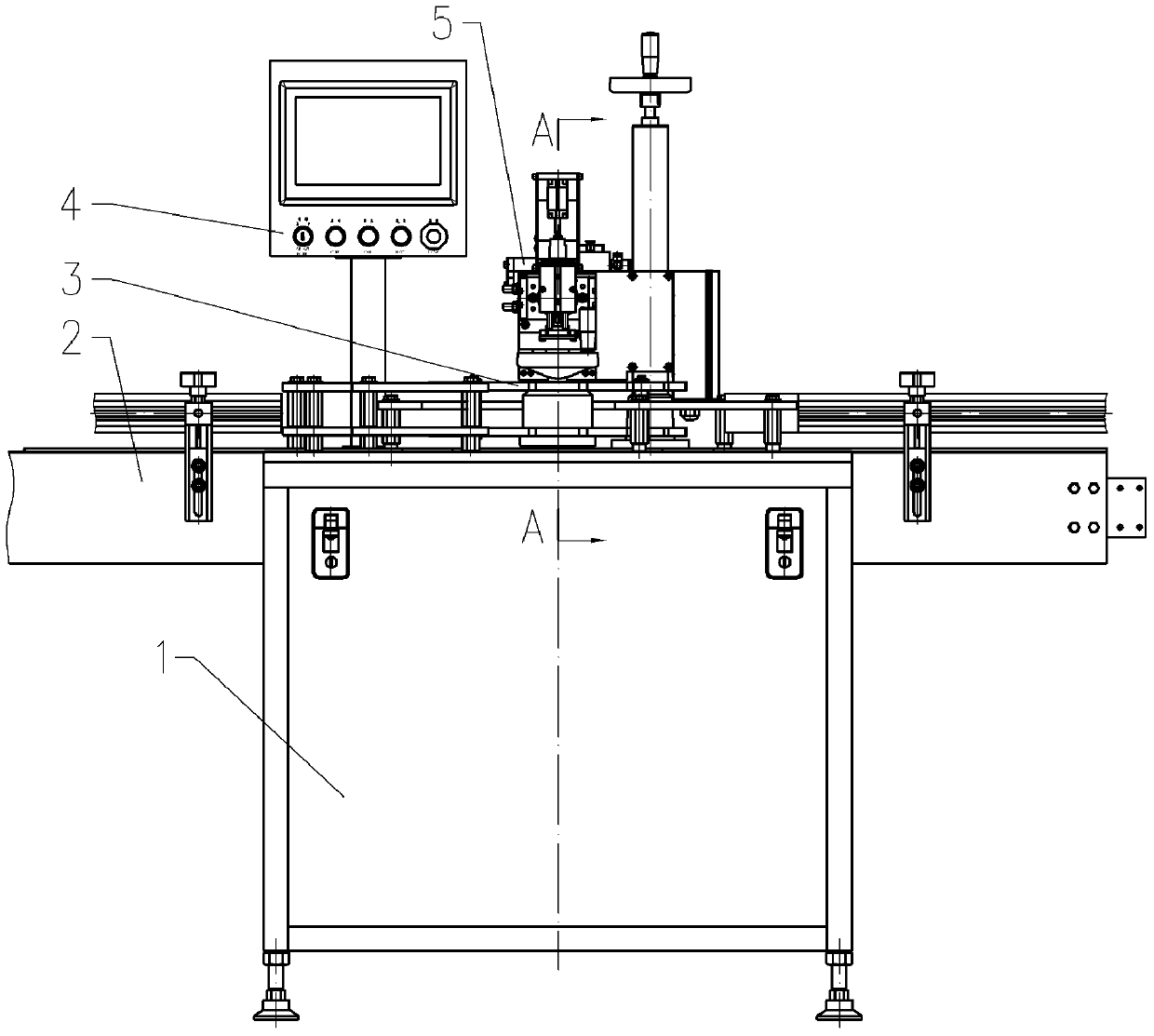

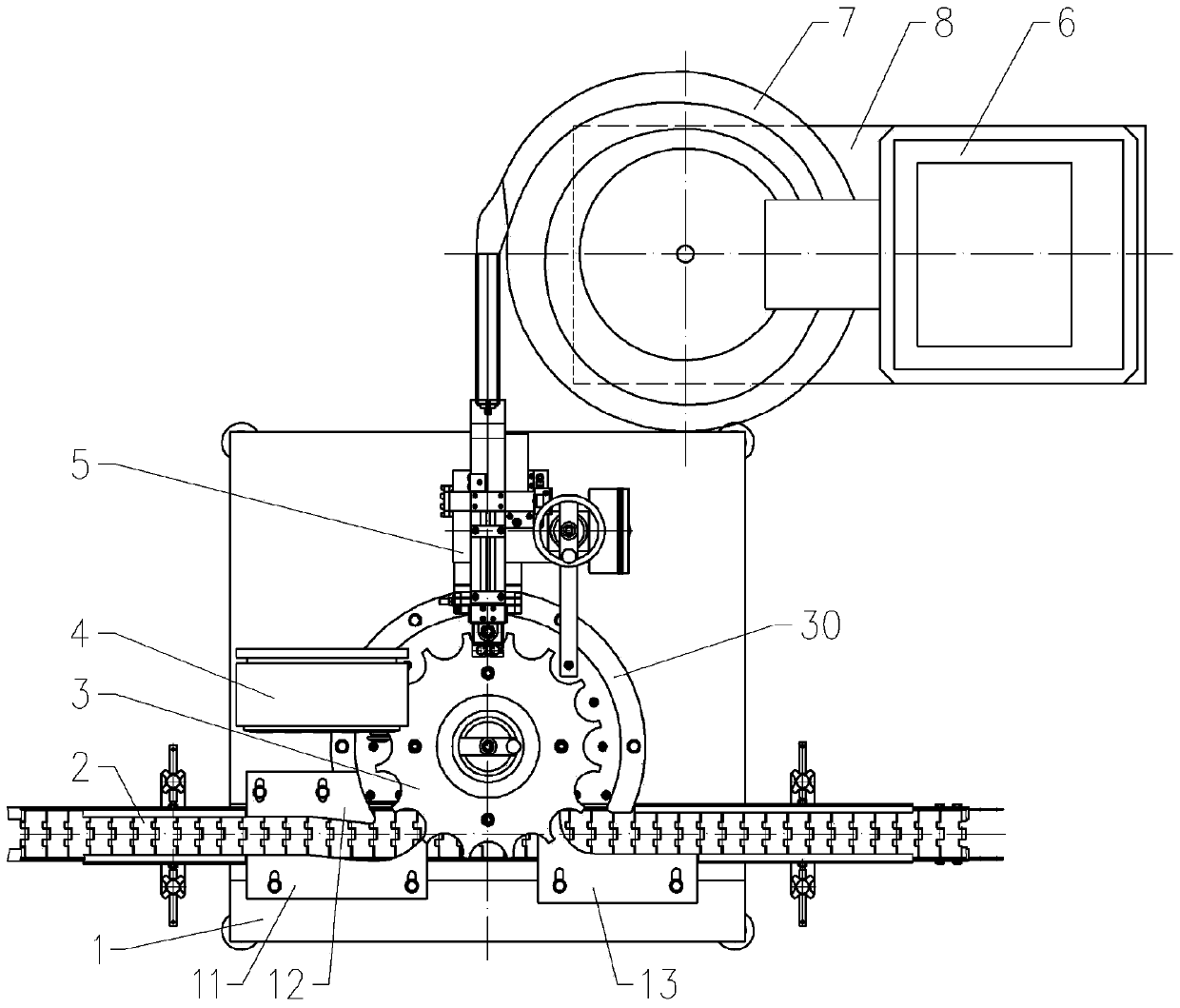

[0029] Such as Figure 1-3 , the present invention is a full-automatic non-draining pipe valve valve release machine, which includes a main frame 1, a machine head 5 arranged on the main frame, a conveying line 2 passing through the main frame, a control box 4, and a The index feed mechanism 3, electric control box 9, hopper 6, valve management vibration plate 7 and vibration plate frame 8 on the frame, the conveying line is used to transport the aerosol cans in a straight line, and transport the aerosol cans to the main machine And the aerosol can with the valve without the suction pipe is transported out of the main machine from the main machine;

[0030] The control box controls the host computer and the index feed mechanism;

[0031] The valve management device is used to transport the valve without the liquid introduction pipe into the machine head;

[0032] The valve regulating device includes a feeding hopper, a valve regulating vibrating plate and a vibrating plate fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com