Collection book automatic patch ticket insertion machine

A fully-automated collection album technology, applied in atlas, printing, etc., can solve the problems affecting the quality stability and processing efficiency of collection albums, restricting the exquisiteness, meticulousness, personalization of collection albums, cervical and lumbar spine lesions, etc., to achieve pasting High efficiency, avoiding high labor intensity, convenient processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

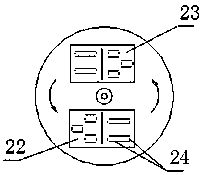

[0028] The center of the invention is to use the page-turning mechanism to automatically turn the pages of the booklet to be pasted, and then use the embossed rubber wheel to roll the glue on the glue position of the entire page at one time, and finally pass the suction cup densely covered with suction nozzles to the page. All the patches to be pasted have been positioned and picked up at one time, and pasted to the corresponding glue position at one time, and repeated in turn to complete the efficient and automatic placement process of the booklet to be pasted.

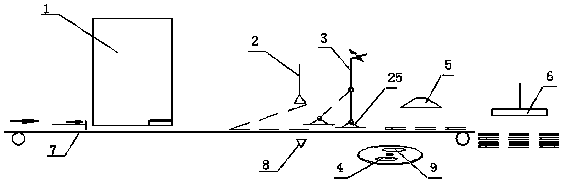

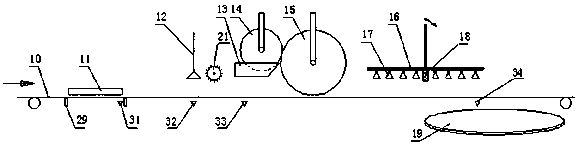

[0029] Attached below figure 1 , figure 2 , image 3 A further detailed description of the fully automatic ticket insertion machine for collection booklets described in the present invention:

[0030] The full-automatic ticket insertion machine for collection booklet according to the present invention includes a controller and a positioning mechanism connected with the controller signal, more than one placement un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com