Device for steel cover box with bottom of deep water high-rise pile cap by hoop-embracing method and construction method

A technology of high pile cap and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of many construction procedures, large material consumption of double-walled steel cofferdam, and difficulty in dismantling fences and supports, so as to achieve expanded application. Scope, quality and safety stability assurance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described below in conjunction with accompanying drawing and embodiment:

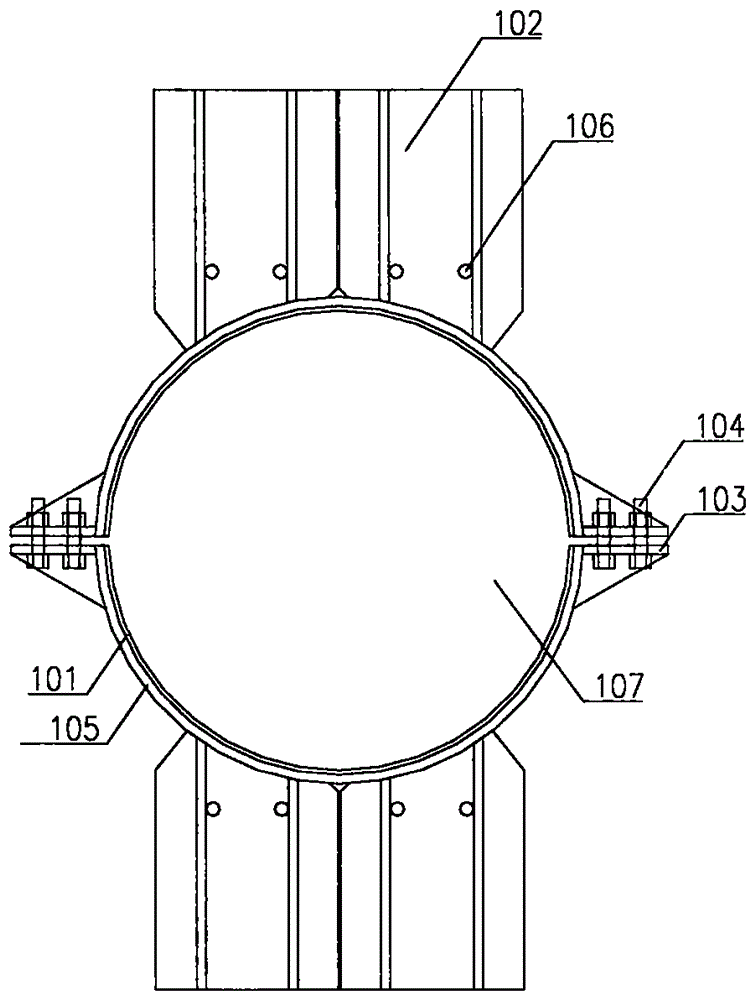

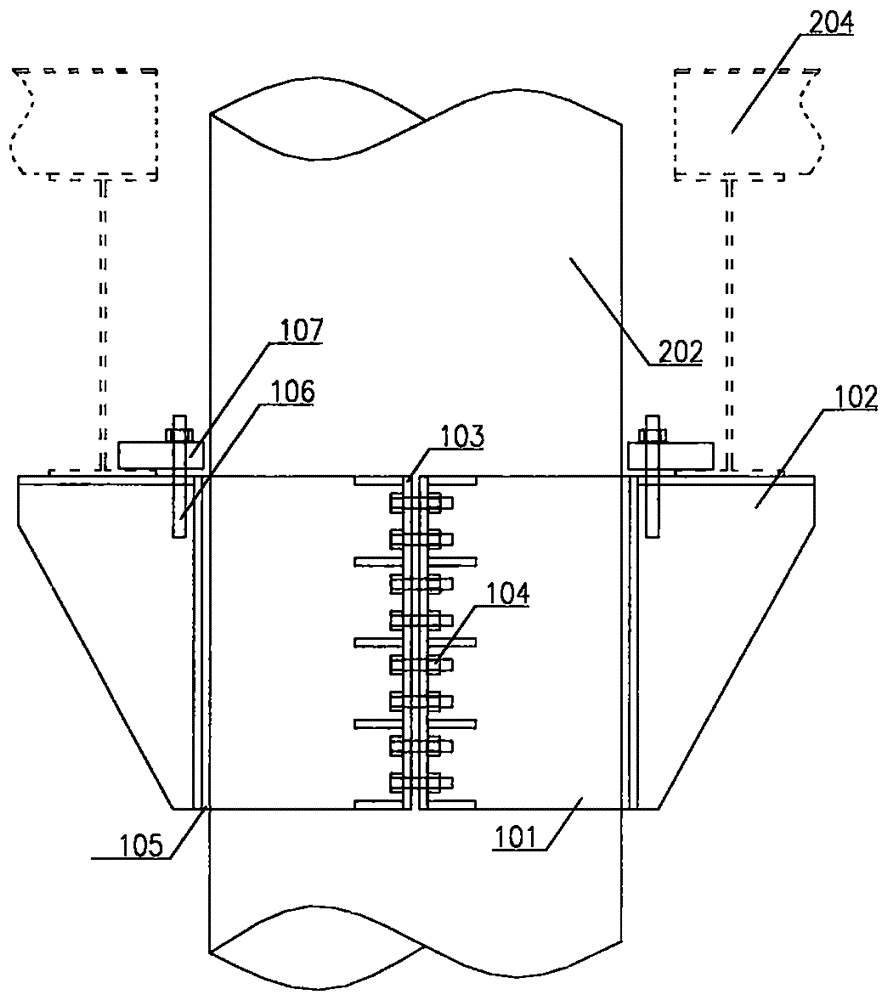

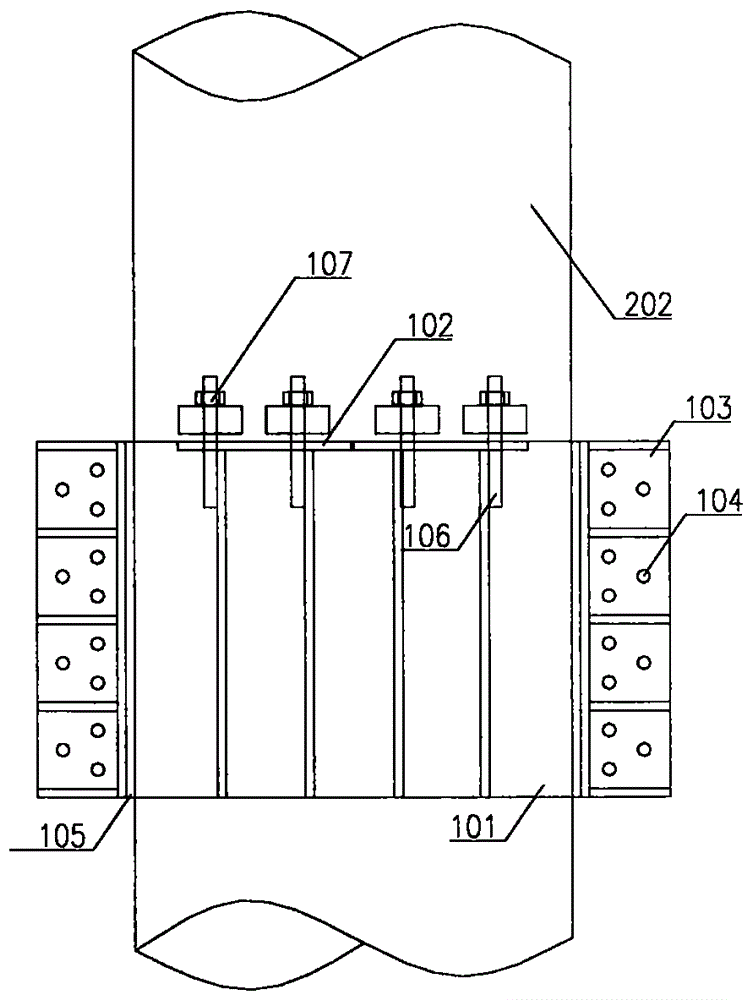

[0048] Such as Figure 1-15 As shown, a deep-water high pile cap hoop method has a bottomed steel casing device, including several concrete pipe piles 202, hoops 201 arranged on the concrete pipe piles 202, and steel casings fixedly connected to the hoops 201 The steel box includes a bottom plate and a side plate 204a fixedly connected to the bottom plate. The bottom plate is provided with a cushion layer 208. The bottom plate includes a plurality of bottom modules 204, a bottom cover plate 205 fixedly connected with the bottom module 204, and a concrete 207 on the bottom cover plate 205. , the bottom module 204 is fixedly connected with the hoop 201, the hoop 201 includes two semicircular steel plates 101, the volume space formed by the connection of the two semicircular steel plates 101 matches the shape of the concrete pipe pile 202, and the two semicircular T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com