Beam bottom steel bar structure with steel bar protection layer thickness controlled by utilizing steel bar supporting framework

A steel protection layer and supporting skeleton technology, which is applied to structural elements, building components, building structures, etc., can solve the problem of excessive thickness deviation of the concrete protection layer at the bottom of the beam, so as to avoid the displacement of the pad at the bottom of the beam and improve the utilization The effect of high efficiency and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

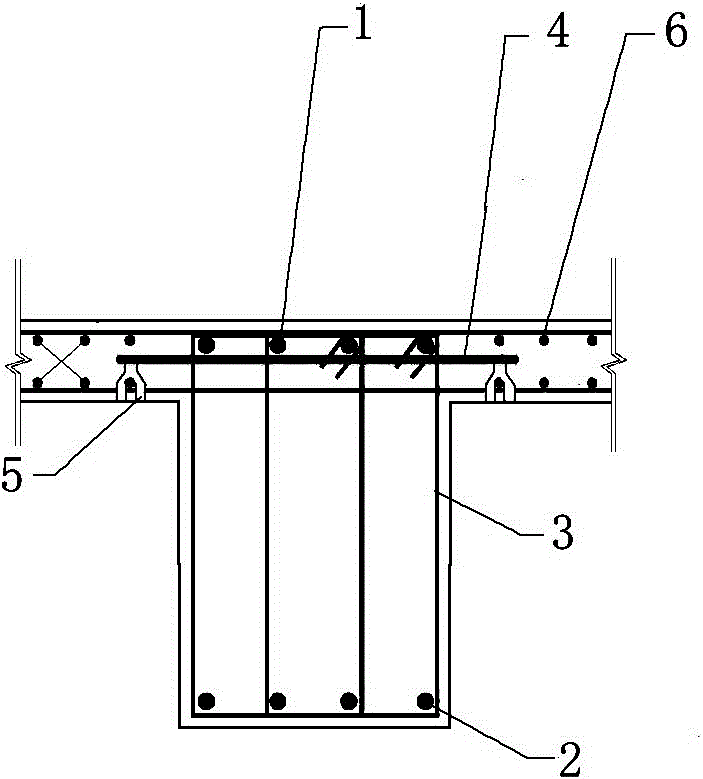

[0034] Such as figure 1 As shown, the steel bar structure at the bottom of the beam, which utilizes the steel bar support frame to control the thickness of the steel bar cover, includes a beam stress bar 1 located at the upper end of the beam, an erection bar 2 located at the lower end of the beam, and a structure for fixing the beam stress bar 1 and the erection bar 2 together. The stirrup 3 also includes a steel bar support frame 4, which is located under the beam stress bar 1, and the steel bar support frame 4 is clamped on the steel bar 6 at the bottom edge of the structural plate through a pad 5, and the bottom of the pad 5 is supported by the concrete protection on the side of the beam On the top of the storey, the general steel support frame 4 is arranged at the junction of the primary and secondary beams. The diameter of the steel support frame 4 is 18-25mm, the length of the steel support frame 4 is 0.5-0.9m, and the block 5 is a plum-shaped concrete block. The height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com