Load modelling method and load control method for wind turbine generator system

A technology for building wind turbines and models, which is applied in the control of wind turbines, engine control, wind power generation, etc., and can solve problems such as failure to achieve control effects and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

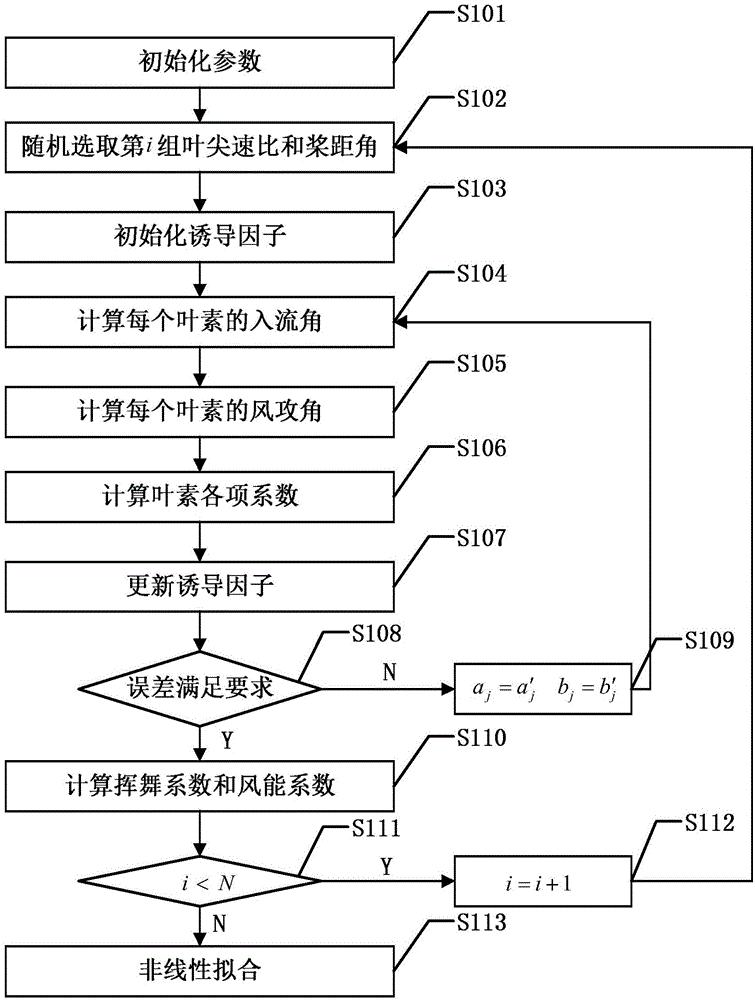

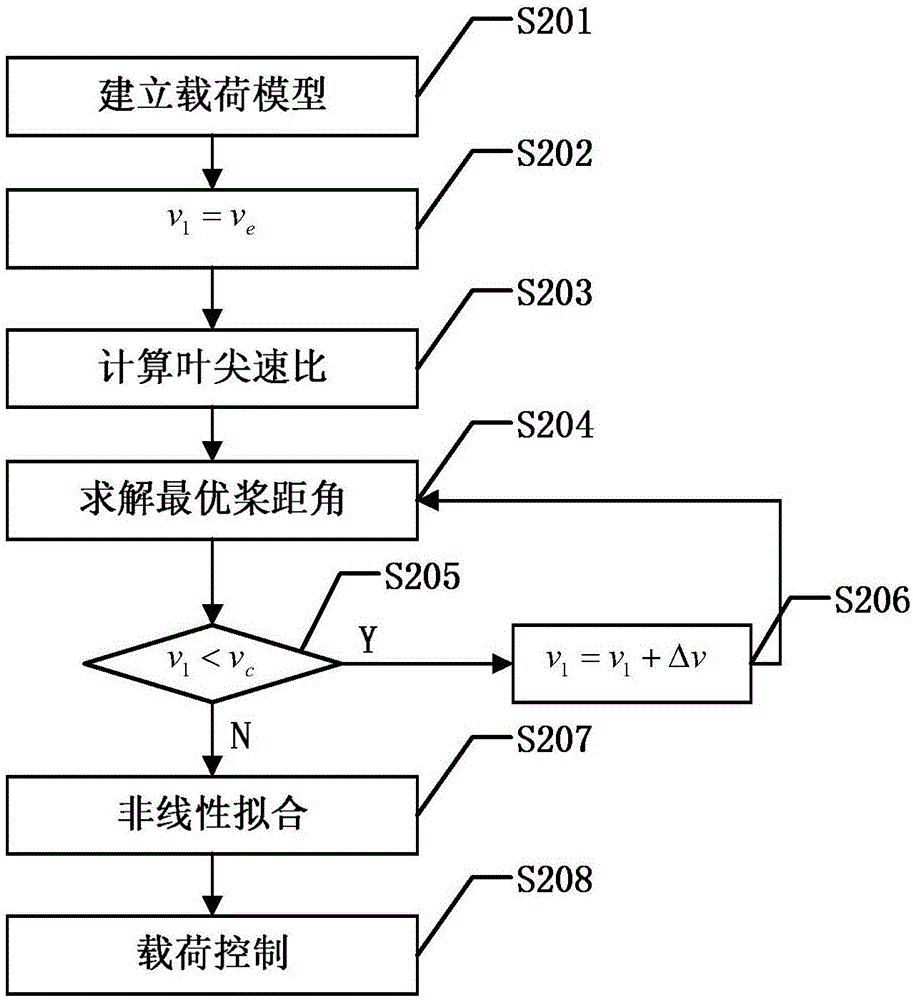

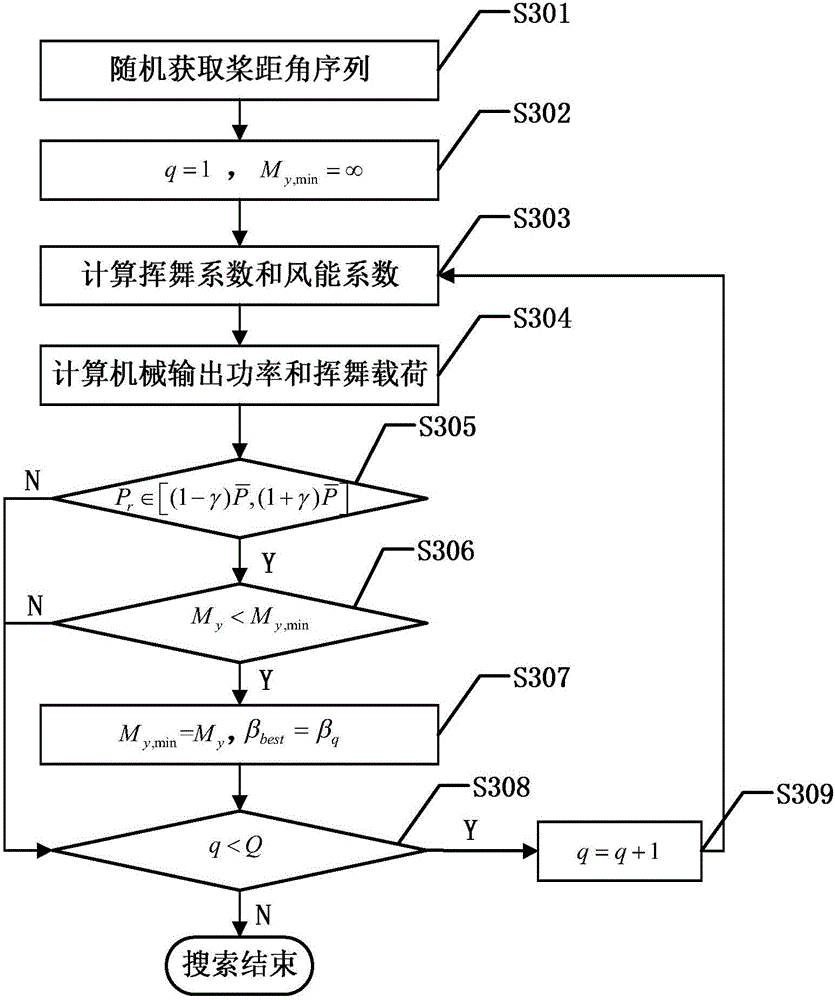

Method used

Image

Examples

Embodiment

[0184] In order to better illustrate the technical effect of the present invention, a 5MW wind turbine of NREL is used to simulate and verify the present invention.

[0185] Firstly, the method for establishing the load model of the wind turbine of the present invention is simulated and verified. In this verification, the present invention selects NREL's 5MW unit parameter data, changes the tip speed ratio from 1.0 to 12.0 at intervals of 1.0, and the pitch angle changes from 0.0 degrees to 8.0 degrees at intervals of 2.0, that is, 12 blades. Tip speed ratio, 5 pitch angles. Figure 4 It is a graph of the wind energy coefficient of NREL's 5MW unit in this example. Figure 5 It is a graph of the waving coefficient of the 5MW unit of NREL in this embodiment. Such as Figure 4 with Figure 5 As shown, when the pitch angle of the 5MW wind turbine of NREL is 0 degrees and the tip speed ratio is 8, the maximum wind energy coefficient can be obtained, which is 48.18%, and the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com