Compressor air filter element

An air filter and compressor technology, applied in membrane filters, mechanical equipment, dispersed particle filtration, etc., can solve the problems of poor filtration effect, small contact area, and contact time interruption, so as to improve the filtration effect and increase the contact area. , the effect of increasing the filtering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

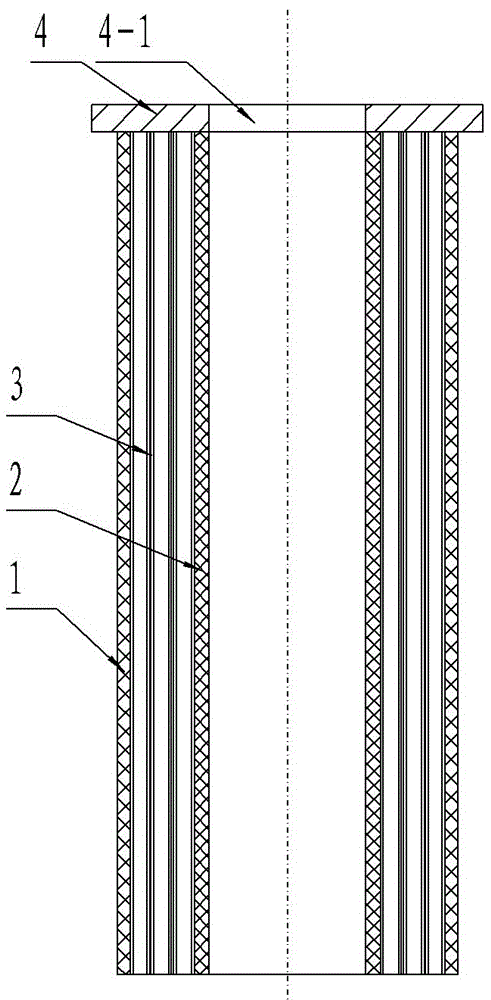

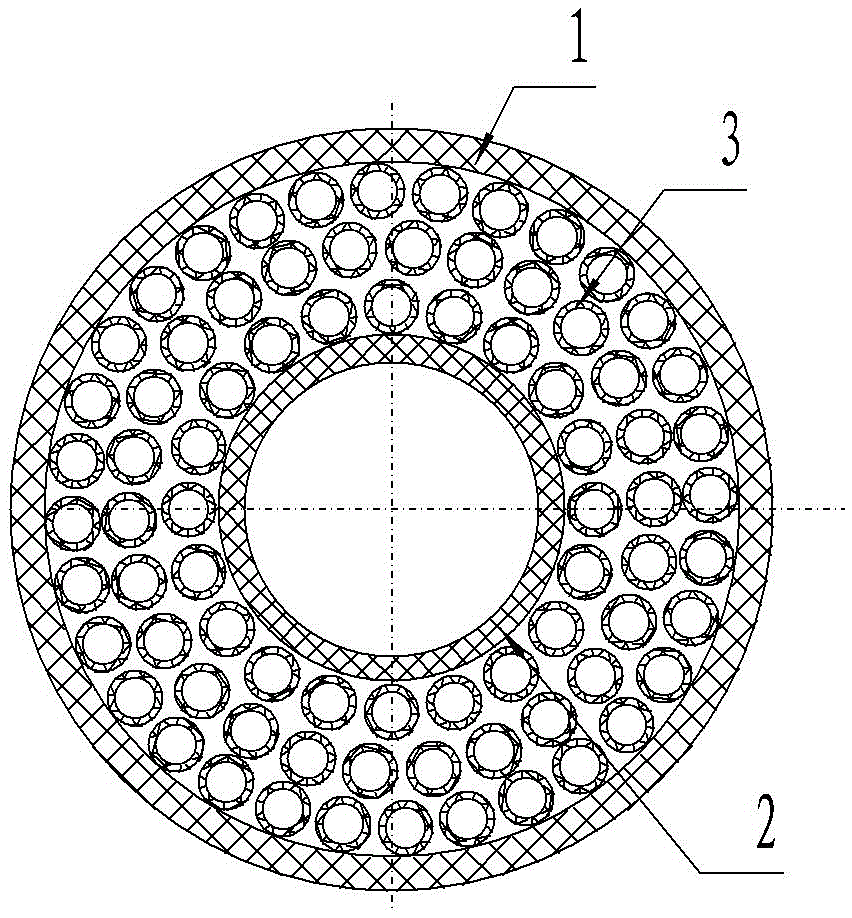

[0011] Such as figure 1 , figure 2 The shown compressor air filter element includes two inner cylinders 2 and an outer cylinder 1 with mesh holes inside and outside, and a top cover 4 is provided on the top between the inner cylinder 2 and the outer cylinder 1, and the top cover 4 There is an air inlet 4-1 in the middle, and there are a plurality of cylindrical filter elements vertically set up between the inner cylinder 2 and the outer cylinder 1. The cylindrical filter elements are carbon fiber cylinders 3. The air flow can not directly pass through, but bypasses between the cylindrical filter elements, which increases the filtration time. At the same time, the bypass air flow can also contact more cylindrical filter elements. The contact area is increased and the filtering effect is improved. The diameter of the air inlet 4-1 is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com