A filter cartridge dust collector capable of cleaning the ash hopper

A technology of filter cartridge dust collector and ash hopper, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of limited filtration time, damage to filter cartridge dust collector, and limited time, so as to improve dust removal efficiency , increase the filtration time, reduce the effect of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

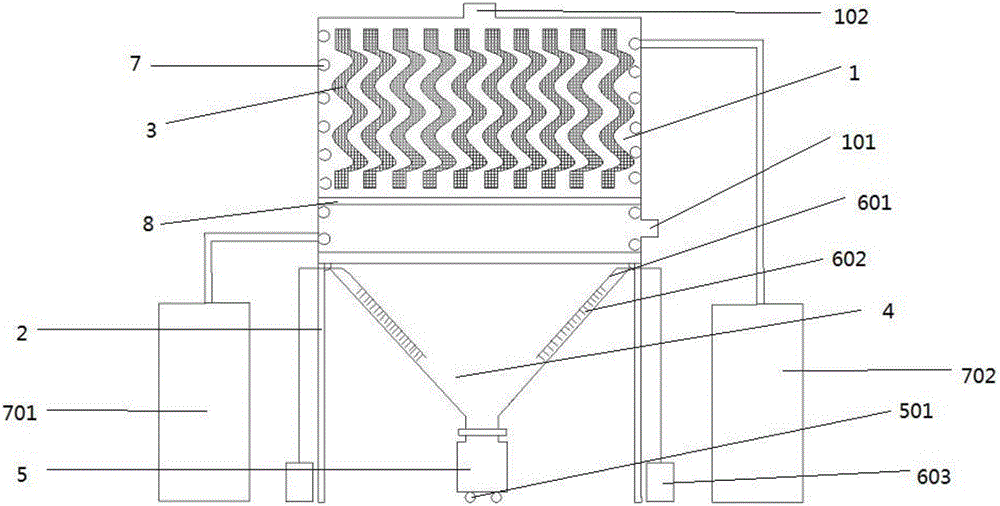

[0018] Such as figure 1 As shown, the present invention provides a filter cartridge dust collector capable of cleaning the ash hopper, comprising:

[0019] Casing 1, it is installed on the support 2, and described casing 1 is the cavity structure that air inlet 101, air outlet 102 are respectively provided with at the bottom and top, and described air inlet 101, described air outlet 102 are all connected with The cavities communicate, and the box body 1 is provided with several filter cartridges 3 parallel to each other, and each filter cartridge 3 is a spiral structure with a circular cross section, which can greatly increase the filtration area and increase the The time for industrial tail gas to pass through the filter cartridge 3, that is, to increase the filtration time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com