Three-ring reducer dedicated to steel billet roll table

A three-ring deceleration, roller table technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of large volume, difficult motor installation, large-area parking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

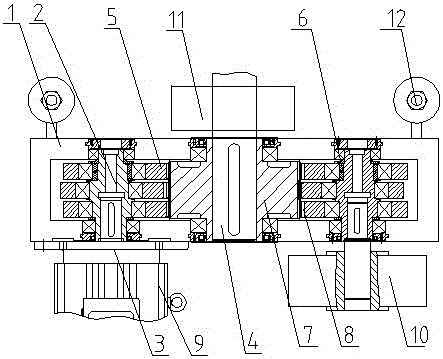

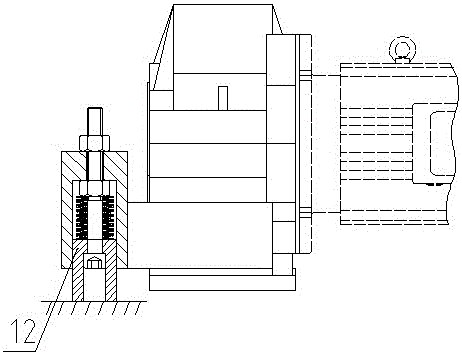

[0012] Below in conjunction with accompanying drawing, the specific implementation manner of technical scheme is described in further detail:

[0013] The special three-ring reducer for the billet roller table includes a box body 1. Three parallel shafts located on the same horizontal plane are installed in the box body 1. The two ends of each shaft are supported on the box body 1 by bearings. The shafts on both sides are eccentric crankshafts. The middle part of the rotating shaft on both sides is a three-section crankshaft 3 with a difference of 120 degrees between adjacent sections. Two sections of the three-section crankshaft 3 have the same diameter, and the diameter of the other section of the crankshaft is smaller than the other two sections. A compensation shaft is sleeved on the crankshaft section with a small diameter. Sleeve 6; the left shaft is the input shaft 3, one end of the input shaft 3 protrudes from the outside of the box body 1 and is connected to the input ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap