Single Tube Sheet Heat Exchanger

A heat exchanger, single-tube technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger sealing devices, etc., can solve the problems of limited use scope and conditions, increased maintenance costs, long maintenance time, etc. The effect of shortening maintenance time, reducing maintenance costs and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

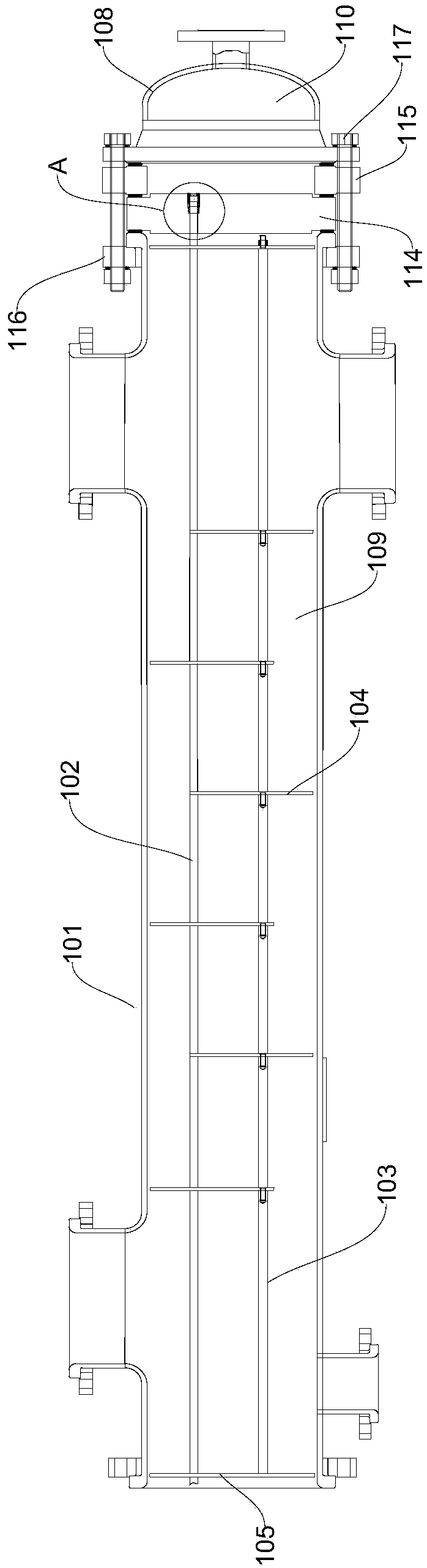

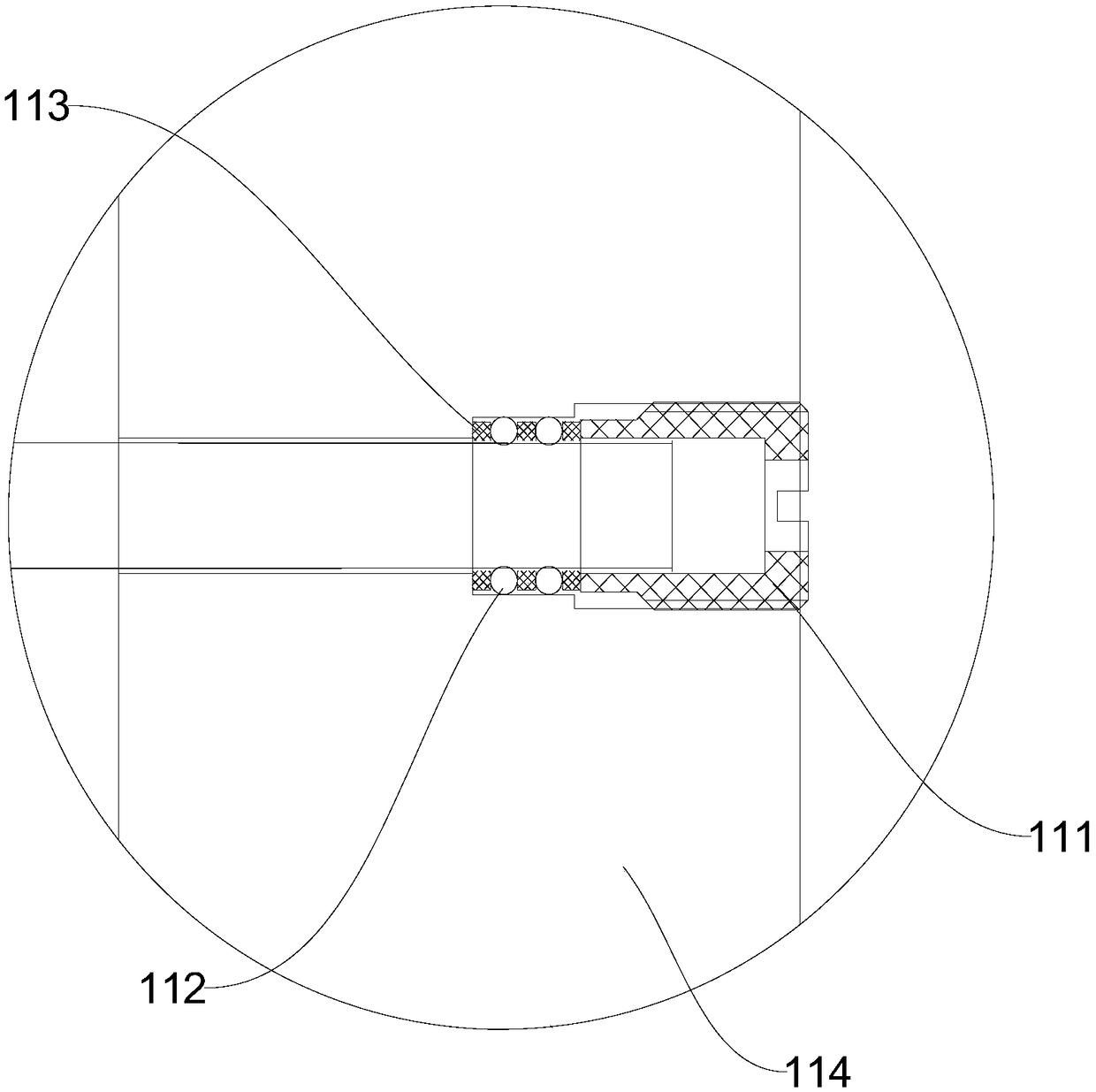

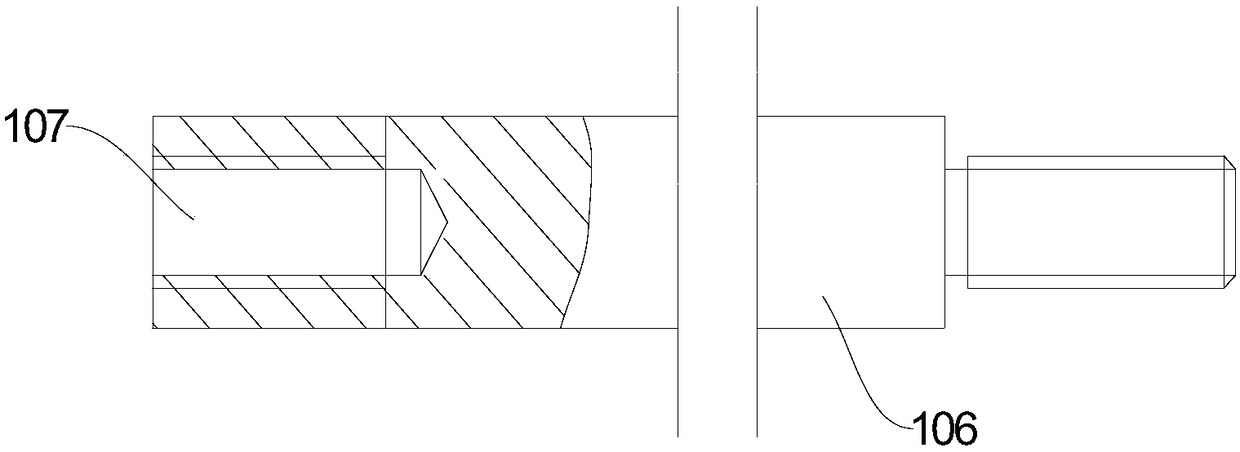

[0035] see Figure 1 to Figure 4 As shown, the present invention provides a single-tube-sheet heat exchanger, including a shell 101, and a baffle device and a plurality of heat exchange tubes 102 are arranged in the shell 101; the axial directions of the multiple heat exchange tubes 102 are parallel to each other; The baffle device includes a tie rod 103; a baffle 104 is fixed on the tie rod 103; a heat exchange tube 102 is installed on the baffle 104; two ends of the tie rod 103 are respectively fixedly connected with a support plate 105 to support the tie rod 103 and the baffle 104 .

[0036] Specifically, the outer surface of the heat exchange tube 102 is supported by the baffle plate 104, which avoids the situation that the heat exchange tube is too long and is easily broken due to force; the baffle plate 104 is fixed on the tie rod 103, and the baffle plate 104 cannot Relative movement occurs with the pull rod 103 , that is to say, the baffle 104 cannot move along the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com