Motor cover and motor housing assembly structure

A technology of motor housing and assembly structure, applied in the direction of electromechanical device, housing/cover/support, electrical components, etc., can solve the problems of low installation efficiency, low installation accuracy of motor cover, inconvenient disassembly and assembly, etc. The effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

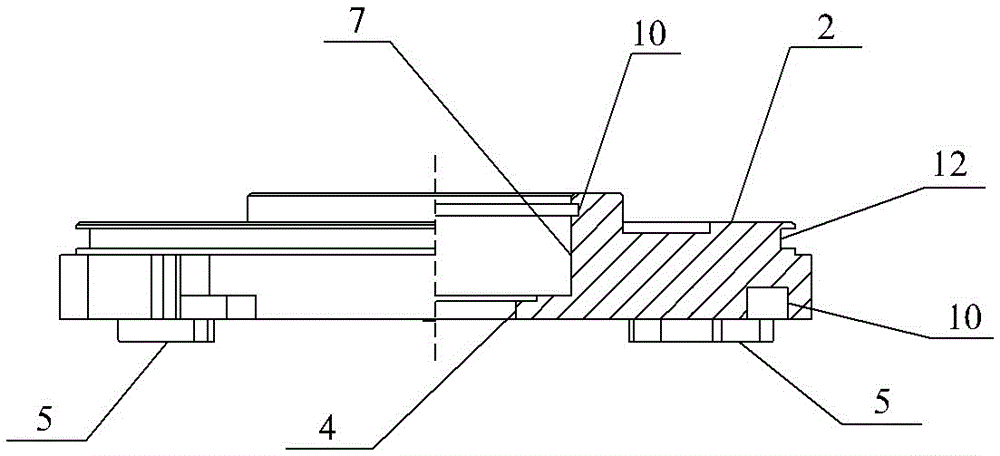

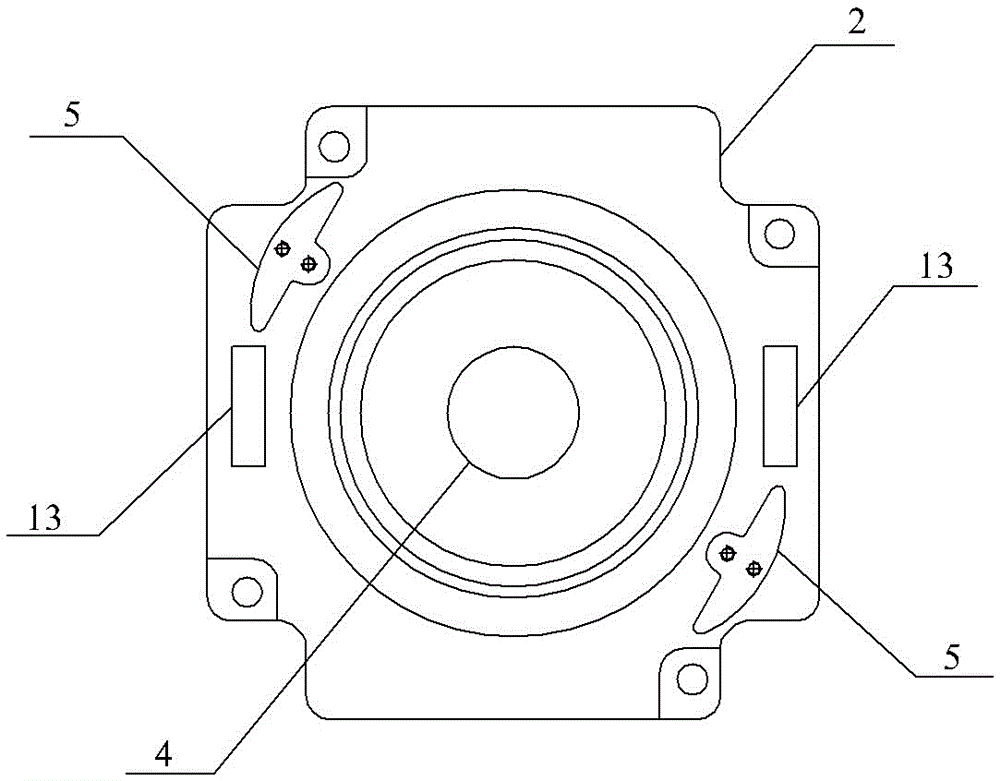

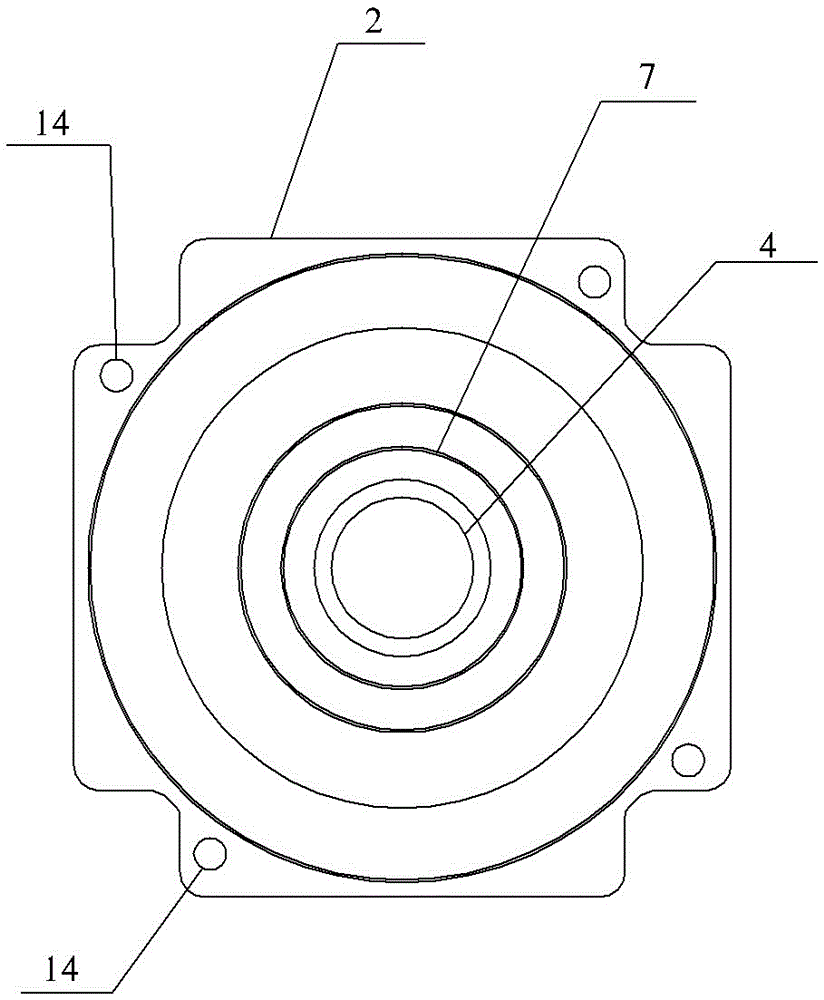

[0017] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, an assembly structure of a motor cover and a motor housing in this embodiment, which includes a motor housing 1 and a motor cover 2, and the motor cover 2 is fixed and covered on the motor housing 1 by bolts. There are 3 openings at the end, which are characterized in that: the motor cover 2 is provided with a shaft hole 4 through which the power supply shaft 8 passes, and at least two positioning blocks 5 are fixed on the bottom surface of the motor cover 2, and the positioning blocks 5 are "convex" The positioning blocks 5 are evenly distributed along the circumference of the shaft hole 4, and the convex end of each positioning block 5 points to the center of the shaft hole 4. The motor housing 1 is provided with two positioning blocks 5 facing each other one by one. The positioning groove 6, the positioning block 5 can be embedded in the positioning groove 6, the top surface of ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 2 Referring to this embodiment, two second grasping grooves 13 are provided on the edge of the bottom surface of the motor cover 2 in this embodiment, and the two second grasping grooves 13 are arranged facing each other. Such design facilitates the grasping of the motor cover 2, and when disassembling, the use of the first grasping groove 12 can make the dismounting and assembling of the motor cover convenient and quick. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 2 To describe this embodiment, the second grasping groove 13 of this embodiment is a rectangular groove. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com