Fuel delivery device for a saddle tank

A fuel delivery and storage tank technology, applied in mechanical equipment, liquid fuel feeders, layout combined with internal combustion engine fuel supply, etc., can solve the problem of only arranging in one of the saddle chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

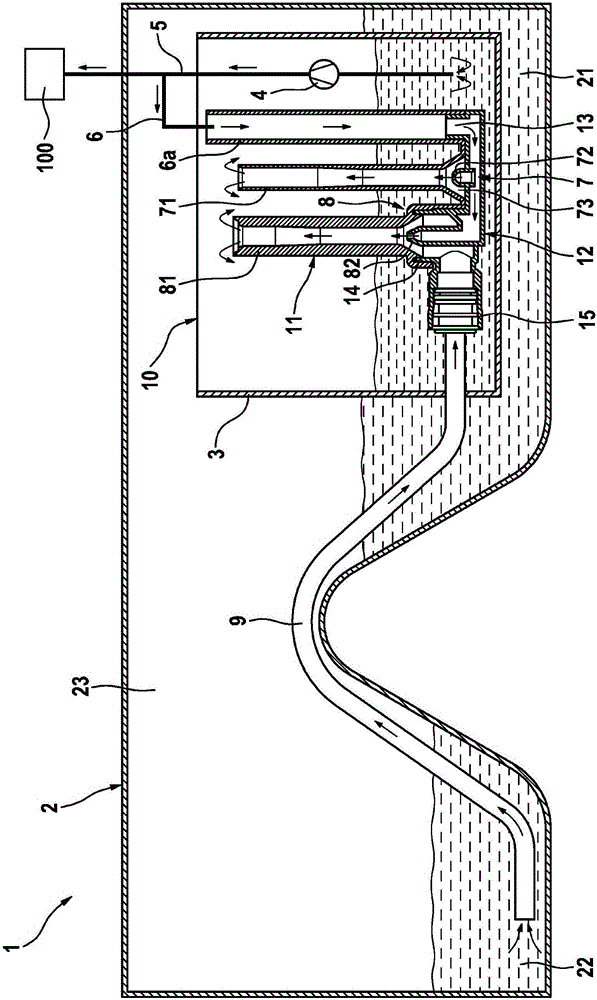

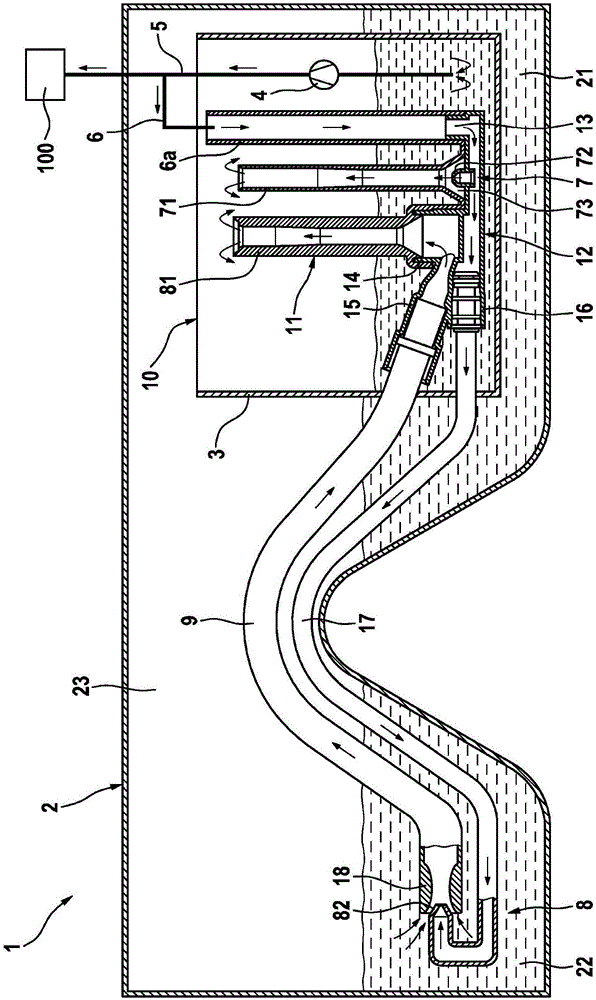

[0017] Next, refer to figure 1 A fuel delivery device 1 according to a first preferred embodiment of the present invention will be described in detail.

[0018] Such as figure 1 As shown schematically, the fuel delivery device 1 is arranged in a saddle tank 2 . The saddle storage tank 2 comprises a first saddle chamber 21 , a second saddle chamber 22 and a bridge connection area 23 connecting the two saddle chambers to each other.

[0019] The fuel delivery system 1 comprises a delivery tank 3 in which a fuel pump 4 and a pre-delivery module for filling the delivery tank 3 are arranged. The pre-delivery module comprises a modular unit 10 with a first module component 11 and a second module component 12, which will be described in detail later.

[0020] A fuel pump 4 delivers fuel from a delivery tank 3 to an internal combustion engine 100 via a fuel delivery line 5 .

[0021] The modular unit 10 comprises two modular components 11 , 12 which are preferably produced by inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com