Tertiary ball mill and tertiary ball-milling system

A technology of ball mill and rough grinding, which is applied in the direction of grain processing, etc., can solve the problems of single function, inability to combine organically, and inability to realize assembly line production, etc., and achieve the effect of single function and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

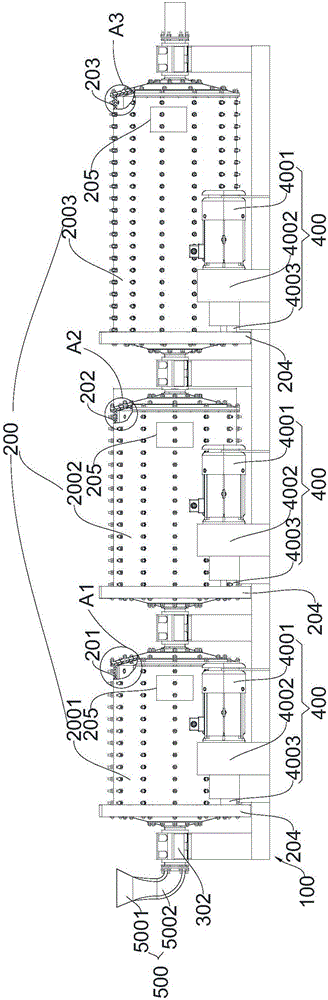

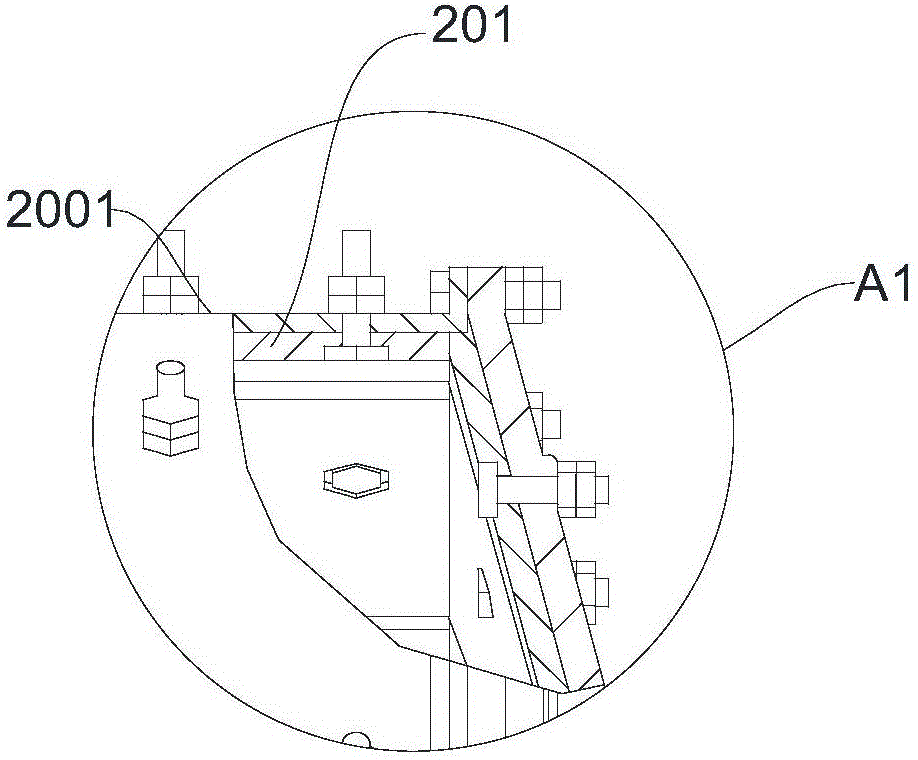

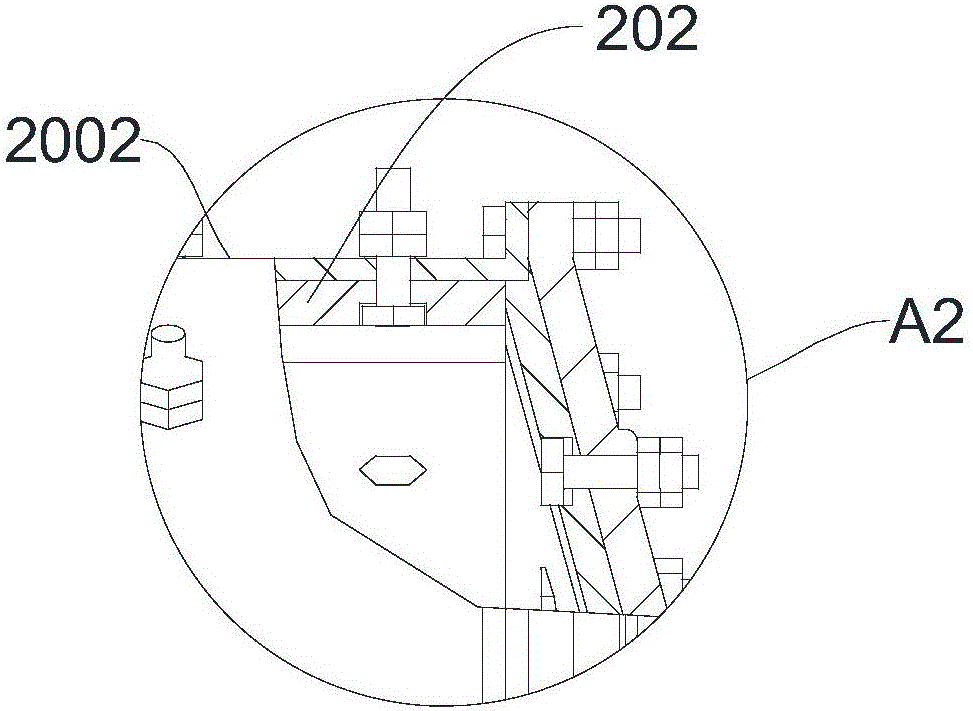

[0040] Embodiment 1, the three-stage ball mill provided by the present invention, such as figure 1 As shown, it includes a base bracket 100 and three cylinders 200, such as Figure 5 As shown, the three cylinders 200 are crushing cylinder 2001, coarse grinding cylinder 2002 and grinding cylinder 2003, respectively, and the crushing cylinder 2001, coarse grinding cylinder 2002 and grinding cylinder 2003 are arranged on the base bracket 100 in order of horizontal rotation; Such as Figure 6 As shown, two adjacent cylinders 200 are connected through a hollow conveying pipeline 300, the crushing cylinder 2001 is also provided with a hollow conveying pipeline 300 for feeding, and the grinding cylinder 2003 is also provided with a hollow conveying pipeline 300 for discharging , the hollow conveying pipe 300 is rotatably arranged on the base bracket 100, and the interior of the hollow conveying pipe 300 is provided with an anti-helical blade 301;

[0041] Such as figure 2 and F...

Embodiment 2

[0055] Embodiment 2, a three-stage ball mill system, including a feeding conveying device, a material collecting device and a three-stage ball mill, the feeding conveying device conveys the material to be processed to the feeding mechanism 500, and the grinding cylinder 2003 is used for discharging The hollow conveying pipe 300 communicates with the material collecting device. The three-stage ball mill system realizes the entire assembly line production of feeding, grinding and discharging, improving production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com