Small bearing washing structure

A bearing cleaning and small technology, applied in the field of bearings, can solve the problems of incomplete cleaning, high price and complex structure, and achieve the effects of simple structure, low cost and short flushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

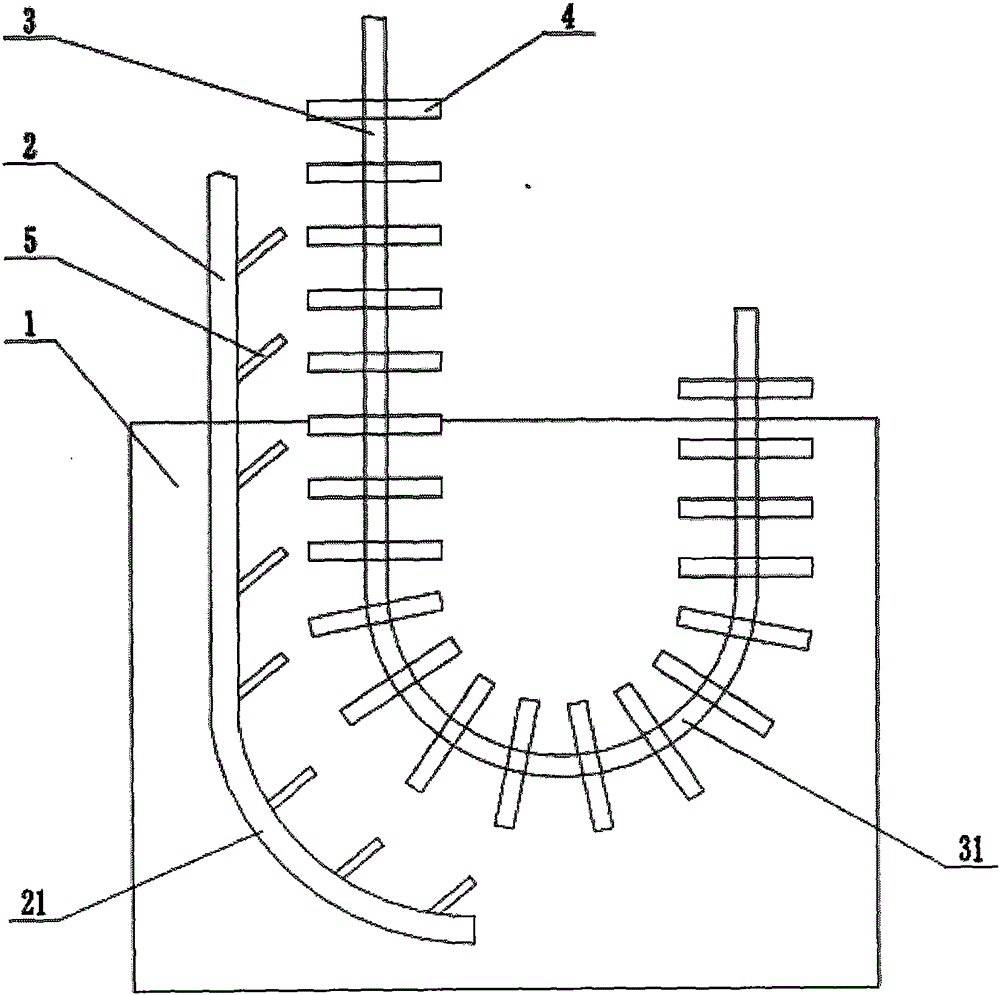

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the small-sized bearing cleaning structure of this embodiment includes a cleaning tank 1, a guide frame 3 with a bearing 4 in the cleaning tank 1 and a spray pipe 2 positioned at the side of the guide frame 3, and the lower end of the guide frame 3 has an extension. Into the U-shaped conduit 31 at the bottom of the cleaning tank 1, the side of the spray pipe 2 is provided with a plurality of spray pipes 5, and the nozzles of the spray pipe 5 are inclined upwards and are arranged towards the bearing 4 on the guide frame 3; the lower end of the spray pipe 2 has There is an arc tube 21 consistent with the direction of bending of the U-shaped conduit 31, and the inner arc side of the arc tube 21 has a nozzle 5.

[0012] In the present invention, the bearing 4 is put in from the upper end of the guide frame 3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com