Optical film electrostatic dust collection mechanism

A technology of electrostatic dust removal and optical film, applied in the direction of electrostatic cleaning, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of limited dust removal effect, time-consuming and laborious, etc., achieve good application prospects, increase dust-absorbing rollers wheel, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

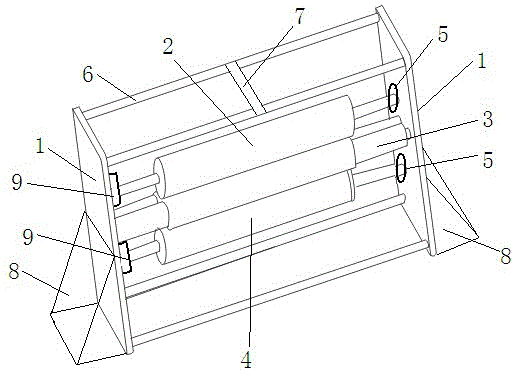

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, the optical film electrostatic dust removal mechanism of the present invention includes support plates 1 arranged symmetrically on the left and right, between the two support plates 1 are provided with first dust sticking rollers 2 distributed sequentially from top to bottom, electrostatic suction Dust roller 3 and the second dust-sticking roller 4, one end of the first dust-sticking roller 2 and the second dust-sticking roller 4 is provided with an electromagnetic brake disc 5, and the electromagnetic brake disc 5 can A dust-sticking roller 2 and the second dust-sticking roller 4 are driven by the servo drive motor to rotate, limiting the rotational speed of the first dust-sticking roller 2 and the second dust-sticking roller 4, which is convenient to adjust its rotating speed, so that It slows down the speed and improves the effect of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap