Front frame structure of skylight of automobile

A technology for automobile sunroof and front frame, applied in vehicle parts, roof, transportation and packaging, etc., can solve the problems of high use cost, difficult installation, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following is a further description with reference to the drawings.

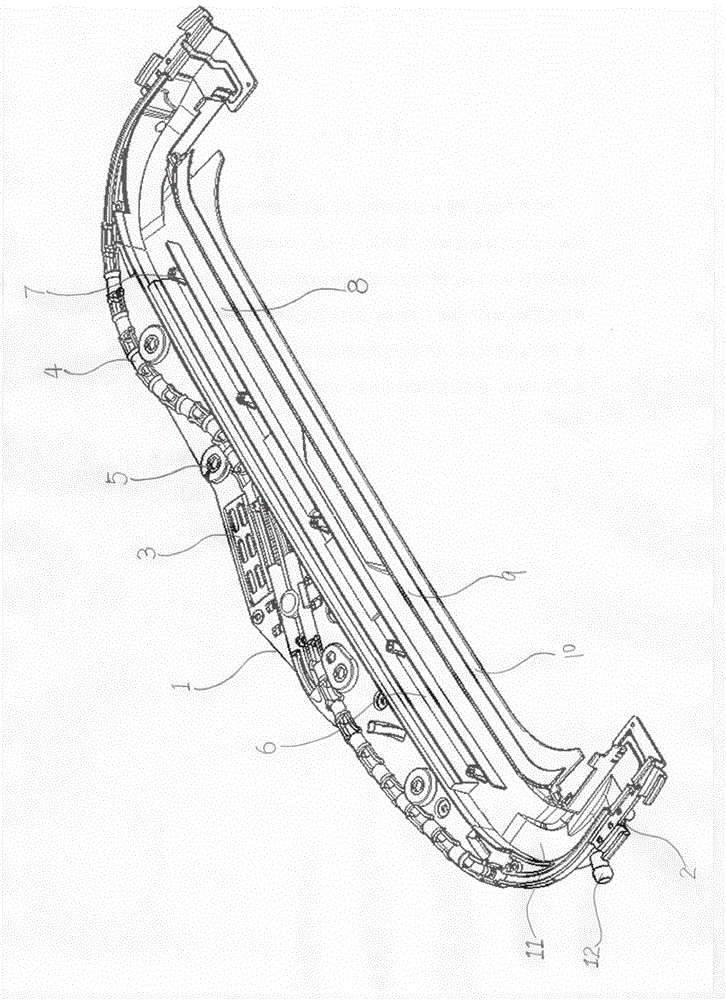

[0009] figure 1 Shown: A front frame structure of an automobile sunroof includes a frame body 1 and two frame bending edges 2. The frame body 1 is arranged at the front of the automobile sunroof and the two ends are respectively integrally injection molded to connect the two frame bending edges 2. From front to back, there are a mechanical group drive system mounting seat 3, two mechanical group drive plastic hose mounting seats 4, a sunroof mounting seat 5, a windscreen mounting bracket slot 6, a windscreen deflector guide rod placement slot 8, and a sunroof Sealing strip sticking seat 9, two mechanical groups driving plastic hose mounting seats 4 are integrally injection-molded to connect multiple limiter through plastic hose fixing seats, two mechanical groups driving plastic hose mounting seats are respectively extended to the bending of two frames On the side, a plurality of windshield mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com