Method and controller of pneumatic adjustment system for failure leakage of speed changer

A technology for adjusting systems and transmissions, applied in transmission control, testing of machines/structural components, instruments, etc., can solve problems such as switching cylinders that can no longer be operated normally, vehicle parking, etc., and achieve simple and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to a method for detecting excessively high or faulty leaks in a pneumatic control system of a transmission, which would lead to the fact that normal gearshifts can no longer take place in the transmission. Such leaks are called fault leaks. Furthermore, the invention relates to a controller for carrying out the method.

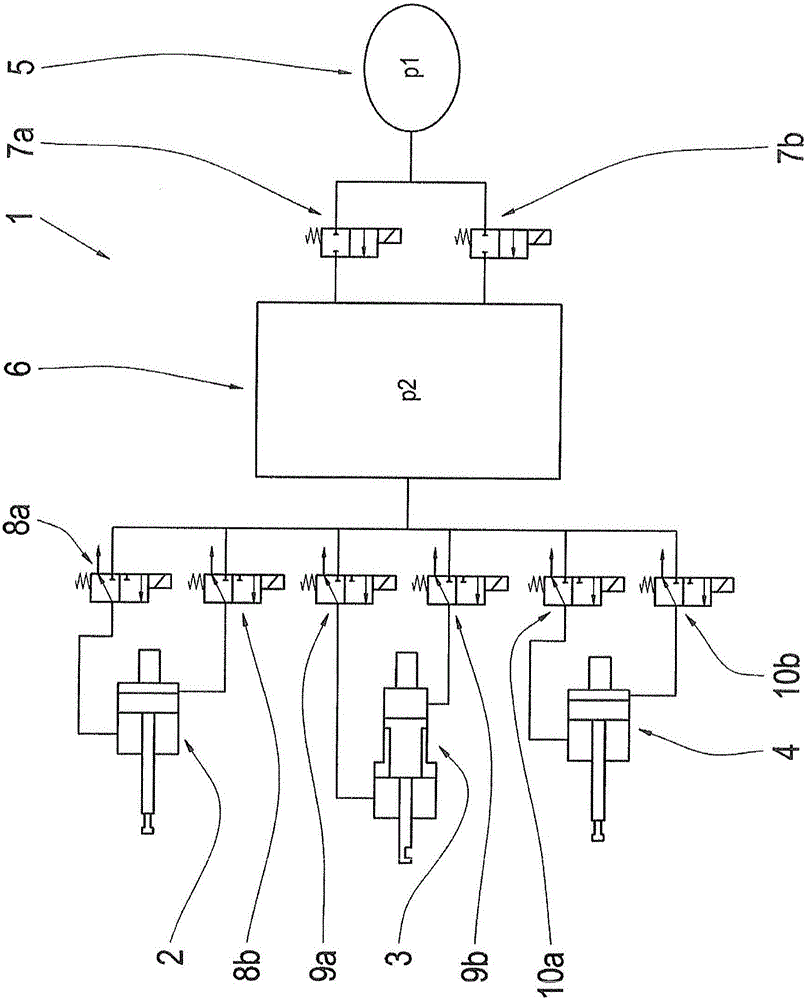

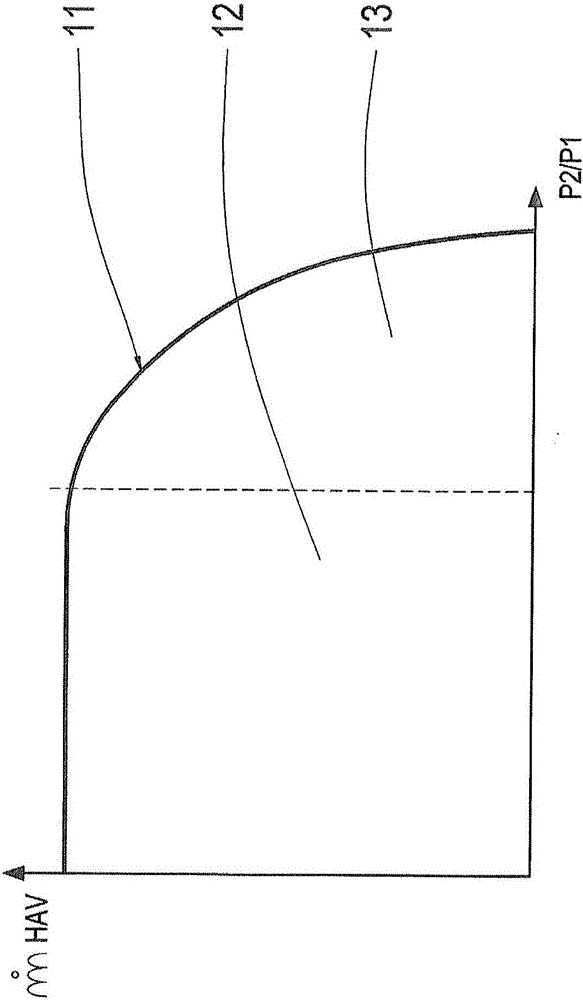

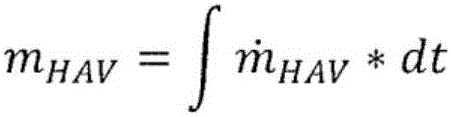

[0018] figure 1 Schematically shows the basic structure of the pneumatic adjustment system for the transmission, that is, in the figure 1 The basic structure of a pneumatic control system for a combined transmission in which at least one pneumatically actuated switching cylinder 2 , 3 or 4 is formed in each transmission part of the combined transmission. figure 1 The shifting cylinder 2 shown in is the pneumatically actuated shifting cylinder of the split gear group of the combined transmission. The shifting cylinder 3 is a pneumatically actuated shifting cylinder of the main transmission of the combined transmission. The shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com