High-impact-resistant wall surface pressure measurement device

A measuring device and wall technology, applied in the direction of measuring blasting force, etc., can solve the problems of poor stability, affecting the test results, unable to obtain the shock wave pressure curve, etc., and achieve the effect of reducing the impact and inhibiting the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

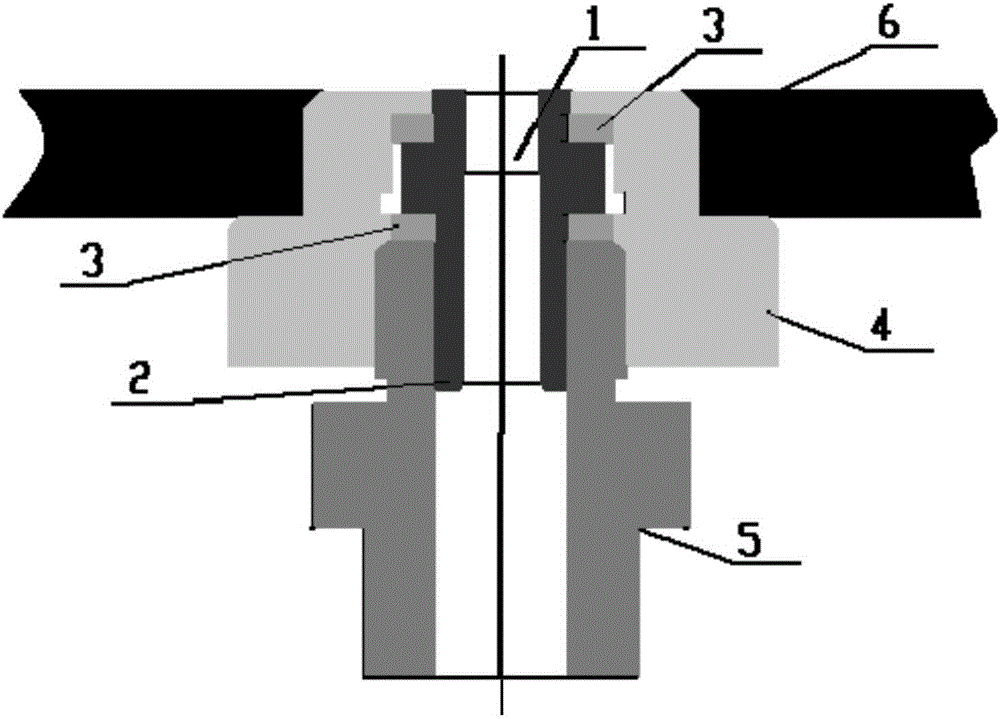

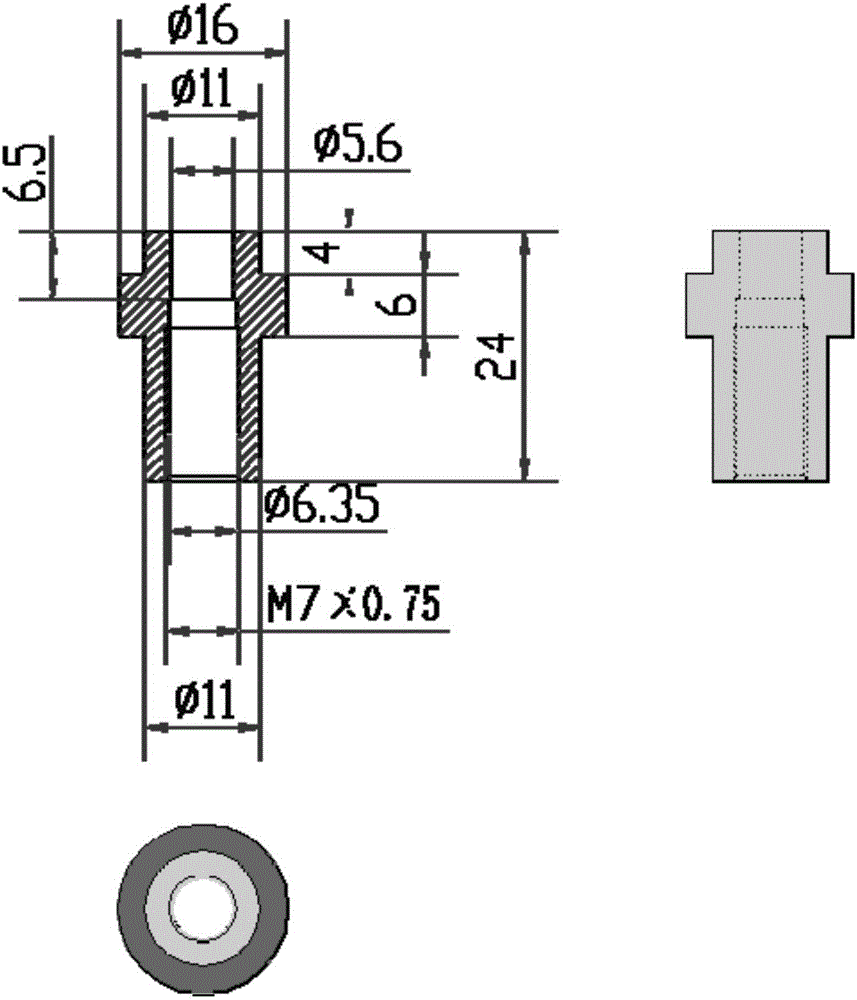

[0023] Such as figure 1 As shown, the preferred embodiment of the present invention is a high-impact wall pressure measurement device, which is composed of a sensor 1 , a mount 2 , an isolation ring 3 , a base 4 , and a compression screw 5 . The sensor 1 is installed in the center hole of the mounting base 2 through threaded connection, there is a copper washer on the shoulder of the sensor, and an isolation ring 3 is respectively installed on the two end faces of the boss of the mounting base 2, and then the mounting base 2 is placed on the base 4 Inside, fasten it by the compression screw 5. The end surface of the mounting seat 2 is flush with the wall surface 6 to avoid disturbance to the shock wave flow field and ensure that the measurement position is consistent with the wall surface.

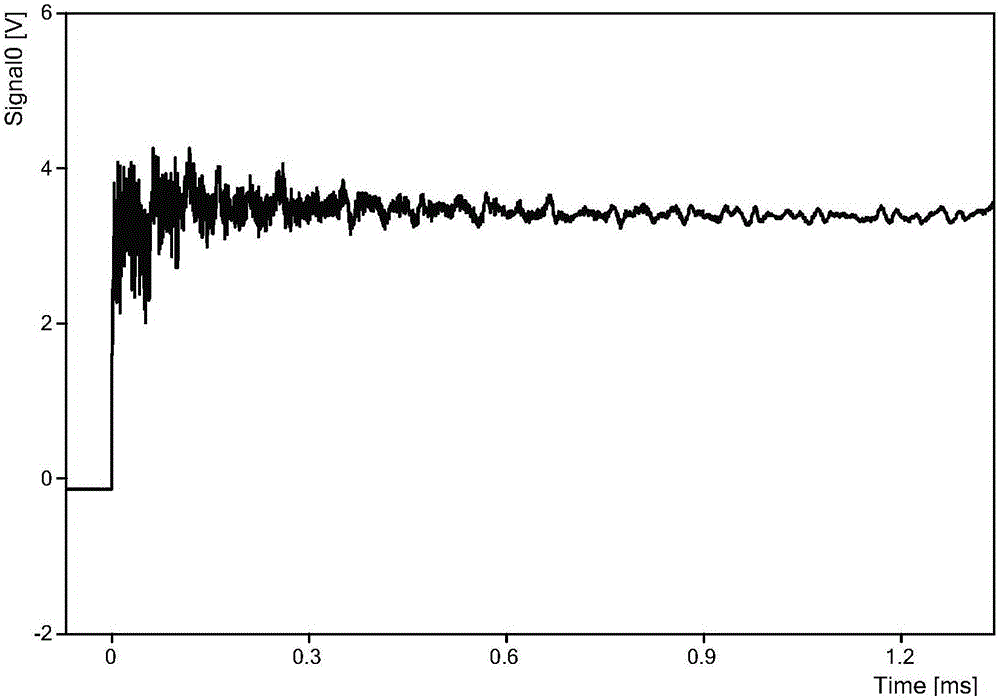

[0024] The vibration isolation of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com