Automatic updating method for petrochemical device agent model

A surrogate model and automatic update technology, applied in design optimization/simulation, constraint-based CAD, complex mathematical operations, etc., can solve problems such as difficulty, non-steady data, and surrogate model accuracy discount, and achieve increased scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: The specific implementation of the present invention will be further described in detail below by taking the construction process of a proxy model of a certain processing device in the planning optimization model of a certain refinery in Shandong as an example. A method for automatically updating a proxy model of a petrochemical plant, specifically as follows:

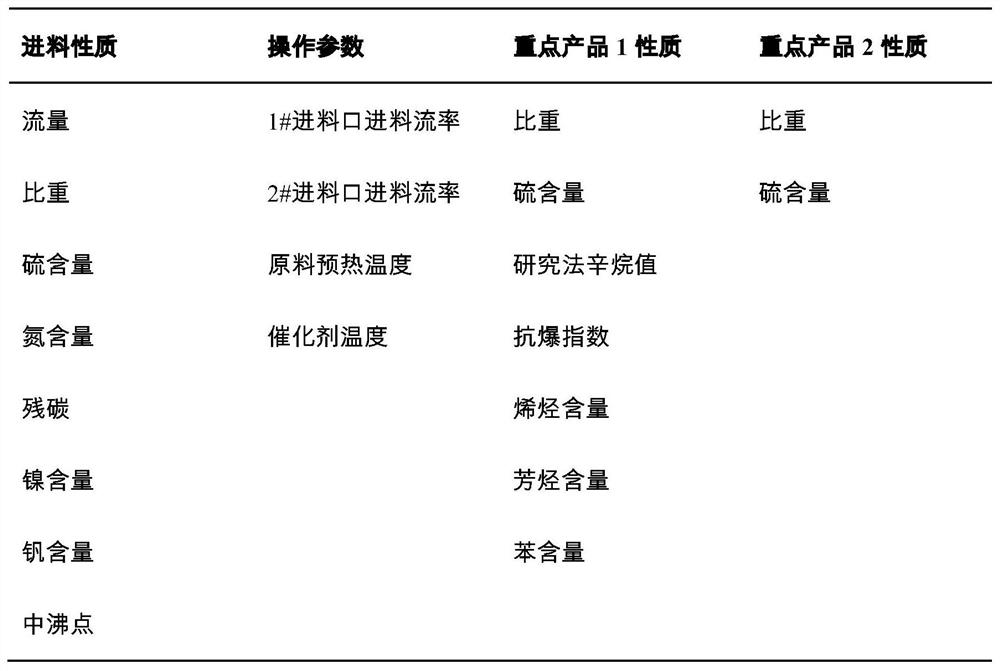

[0036] 1. Comprehensive statistics of DCS instrument data, LIMS data, laboratory analysis data of raw materials and products of the device, online analyzer data and other data from different sources of the refinery, combined with actual production conditions, and the overall design of the plan optimization model, determine the construction The source of data required for the modeling of the proxy model of the device is manually processed to form the data required for the modeling of the proxy model of the device. After selection, the property data used to establish the agent model of the device are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com