A method for on-line performance monitoring of thermal power generating units based on component characteristics

A thermal power generation unit and component technology, applied in the direction of electrical program control, comprehensive factory control, program control, etc., can solve the problems of lack of fault discrimination mechanism, reflection of thermal system components, failure of component failure alarms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

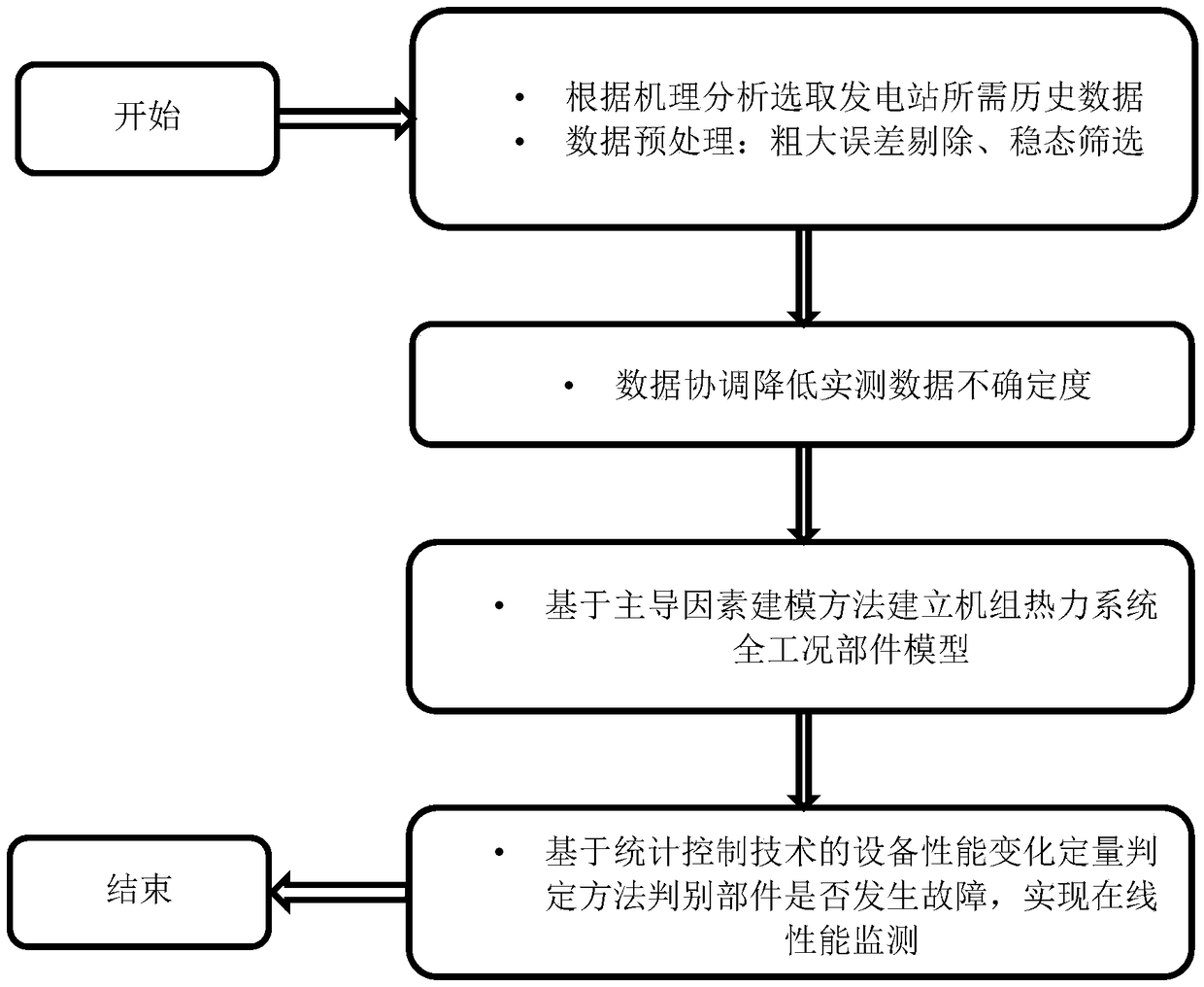

Method used

Image

Examples

Embodiment

[0138] Example: Build an online performance monitoring platform for a 330Mw thermal power generating set

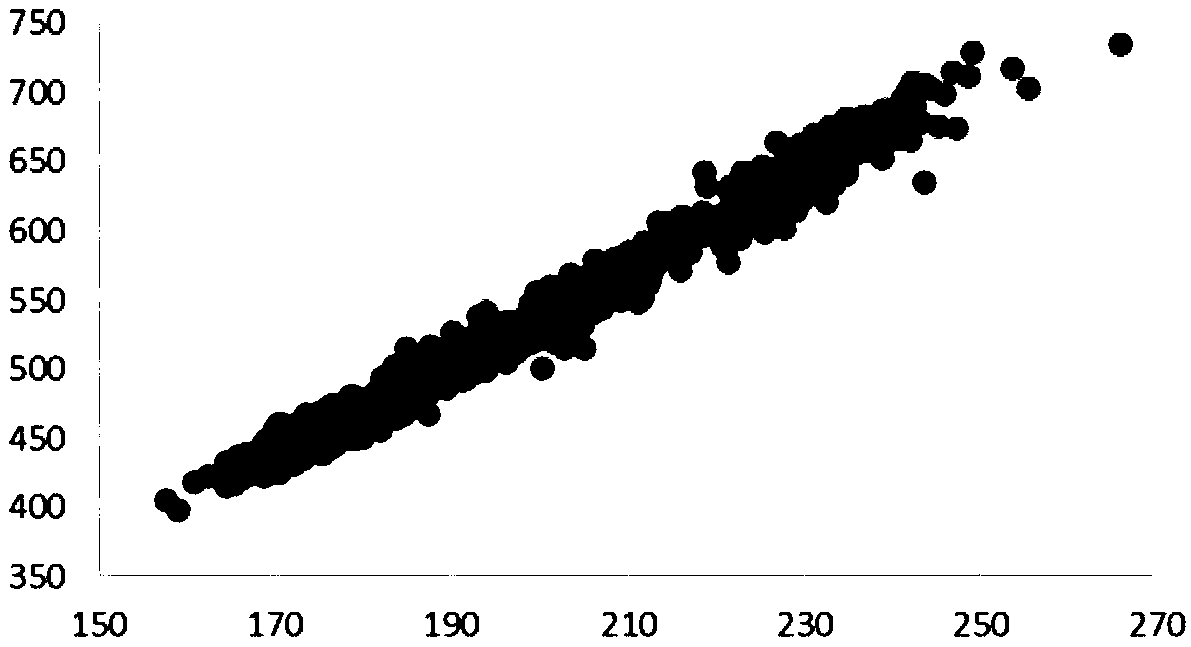

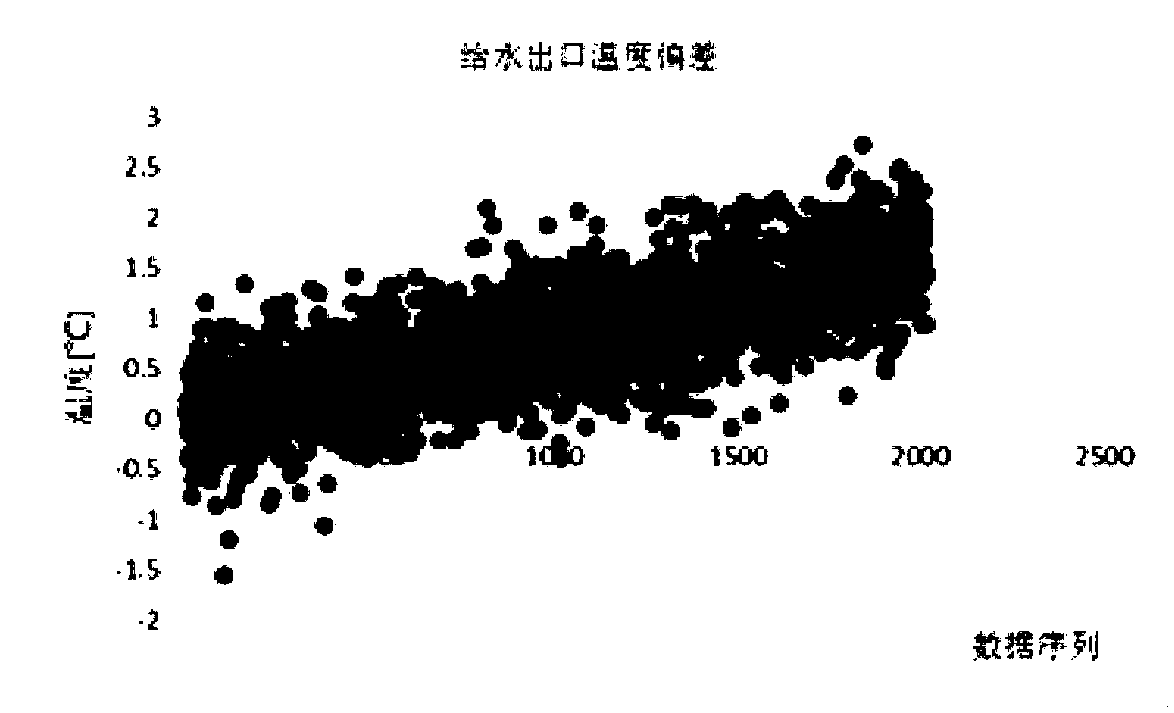

[0139] In view of the changing coal quality and frequent load changes faced by thermal power units in Shanxi Province, develop a new generation of energy-saving monitoring technology for thermal power units under the premise of ensuring the safety, economy and reliability of thermal power units: study the full working conditions of thermal equipment component level / equipment / system High-precision mathematical modeling technology, unit performance monitoring method based on dynamic and static models; establish a dynamic / static mathematical model operation platform for thermal equipment, a measurement data correction platform based on redundant information, and an online monitoring and abnormality screening platform for thermal equipment operation performance; In Shanxi Zhangdian Tongda Power Generation Co., Ltd. 330MW thermal power unit, the energy-saving monitoring demonst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com