Damper for nuclear fuel transport container

A technology for transport containers and shock absorbers, which is applied in portable protective containers, nuclear engineering, etc., can solve the problems of lack and high impact resistance, and achieve the effects of reducing impact, increasing impact resistance, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

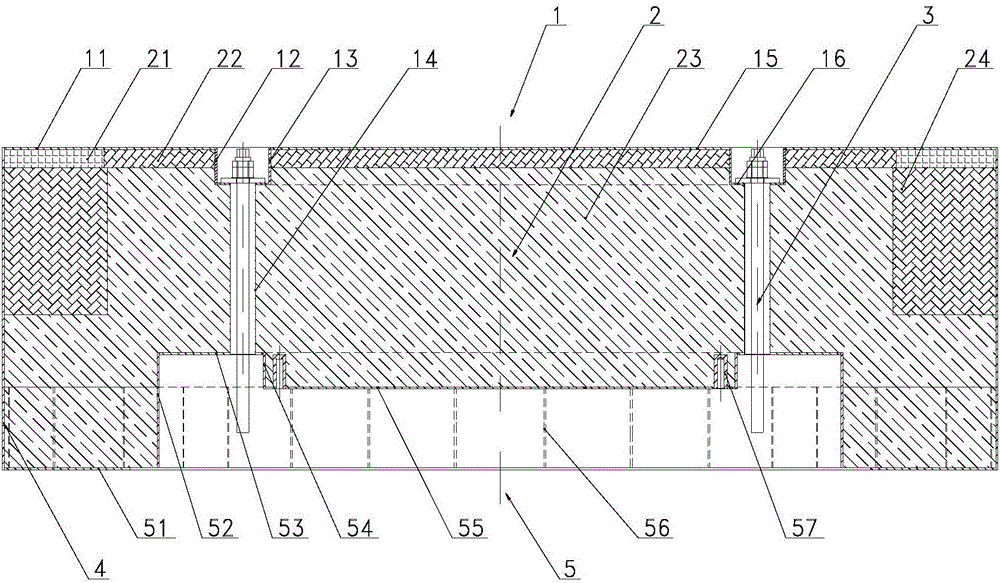

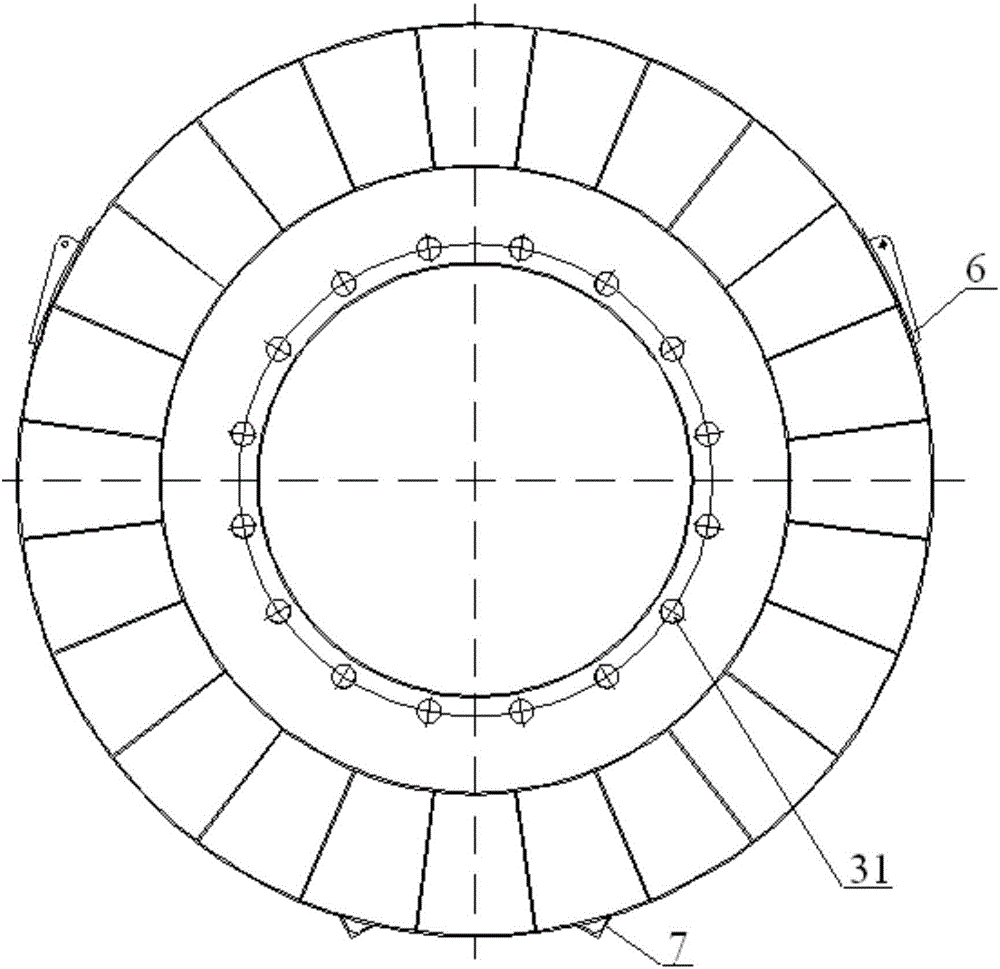

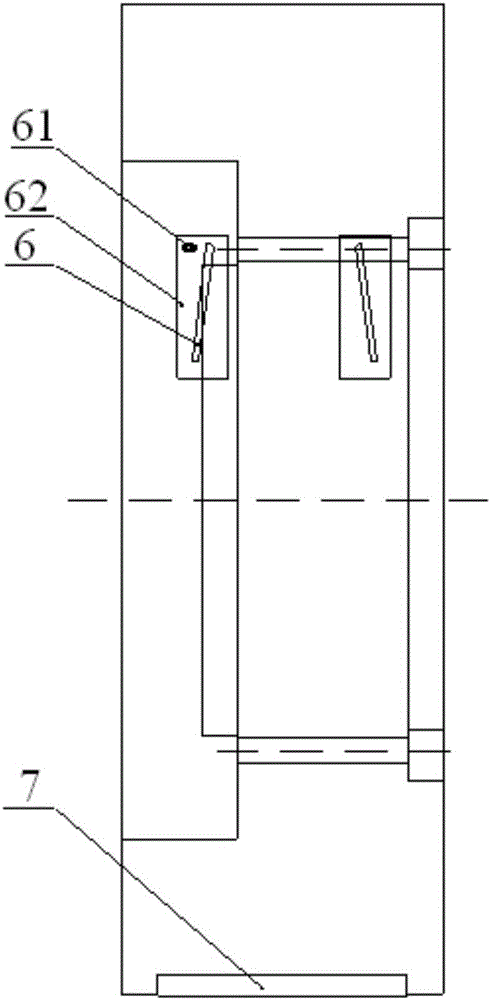

[0024] Such as Figure 1-3 Shown is the shock absorber for the nuclear fuel transport container provided by the present invention. The shock absorber is used in conjunction with the transport container and is installed on both ends of the transport container through bolts to absorb the impact energy under normal transport and accident drop conditions. , to ensure the safety of nuclear fuel transportation.

[0025] The shock absorber includes a stainless steel cavity made of an outer end frame 1 , an outer ring plate 4 and an inner end frame 5 . The inside of the cavity is filled with buffer material 2 to improve the impact resistance of the nuclear fuel. The buffer material 2 is composed of wood with different densities and staggered grain directions. The buffer material 2 is arranged in partitions, wherein the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com