Pressure arm type bolt clippers

A technology of bolt cutters and pressing arms, applied in the field of bolt cutters, which can solve the problems of breaking wires, high labor intensity and difficulty in live work, and large breaking torque, and achieves small resistance, easy hanging and fixing, and convenient length Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

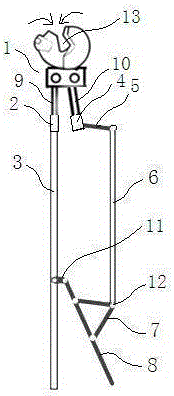

[0018] Accompanying drawing is a kind of specific embodiment of the present invention.

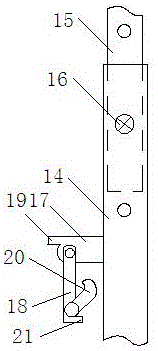

[0019] Such as figure 1 As shown in , this embodiment includes a bolt cutter body 1, the first tong arm 9 of the bolt cutter body is fixedly connected to the operating rod 3 through the fixing buckle I2, and the rear part of the operating rod is provided with a mounting seat 11, on the mounting seat A pressing arm 8 is hinged, and two connecting rods III7 are connected to the pressing arm, and the other ends of the two connecting rods III are connected to form a connection point 12. The second clamp arm 10 of the bolt cutter is fixedly connected to the connecting rod through the fixing buckle II4 I5, the other end of the connecting rod I is hinged with the connecting rod II6, and the other end of the connecting rod II is hinged at the connection point 12.

[0020] The jaw of the bolt cutter body is a "U-shaped" hook jaw 13 with a crotch structure. The jaw clamps the wire to be broken thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com