Coiler device provided with chute roller

A technology of winding device and chute roller, applied in manufacturing tools, metal processing equipment, metal rolling, etc., can solve the problems of large bulging of metal plates, inability to coil metal plates, and inability to guide metal plates smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

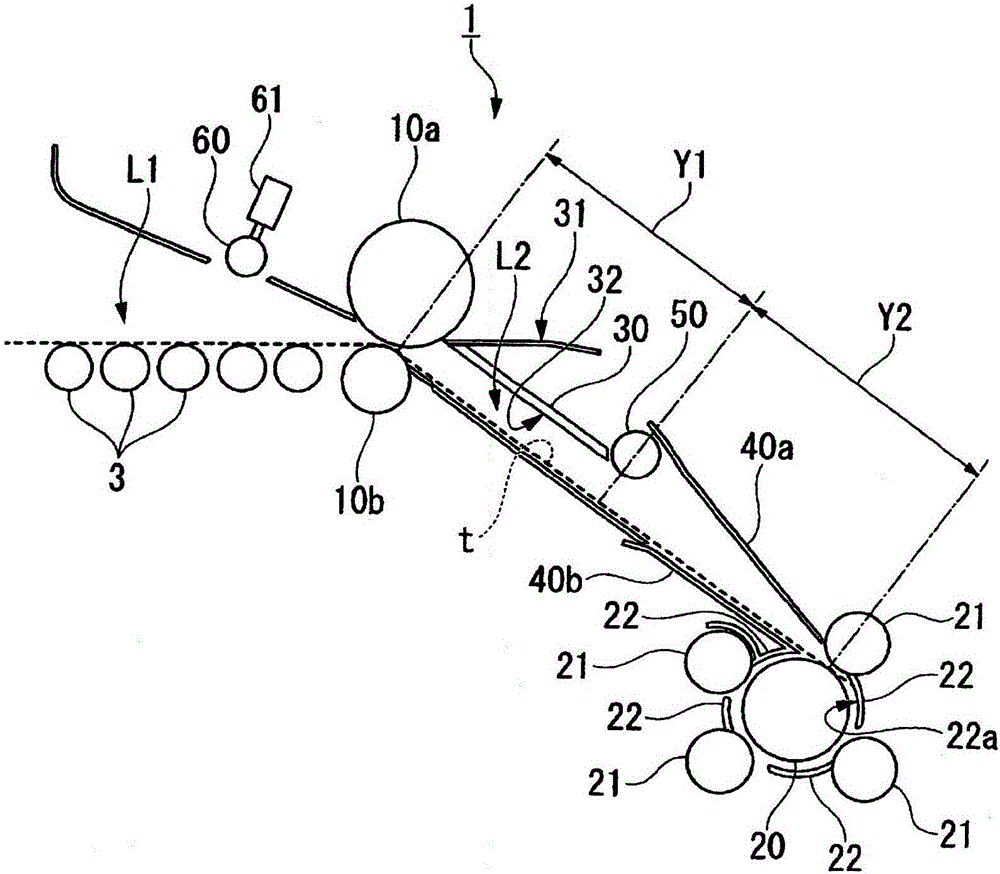

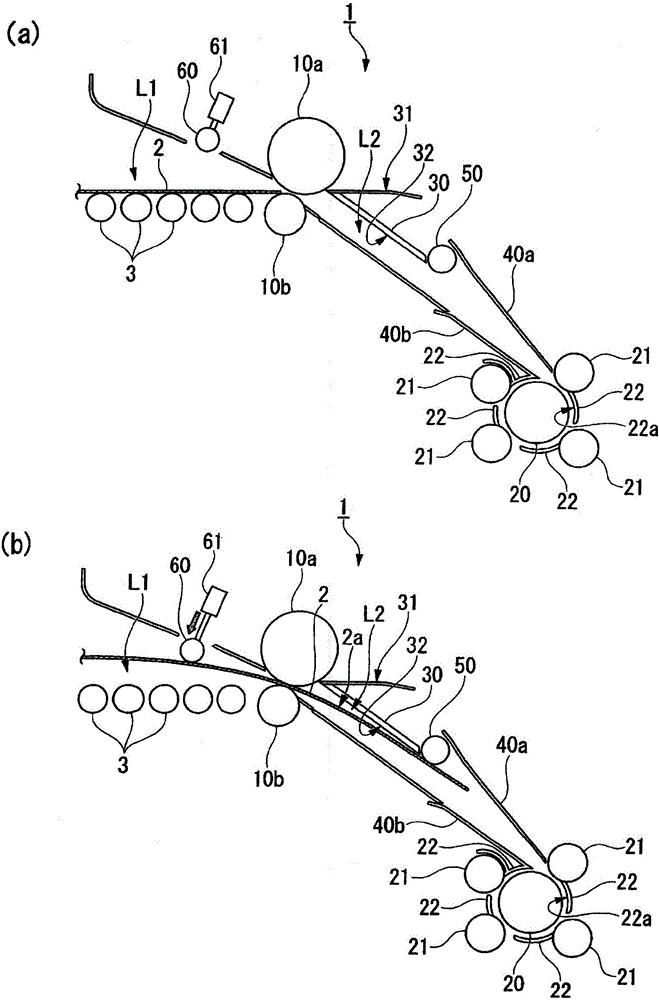

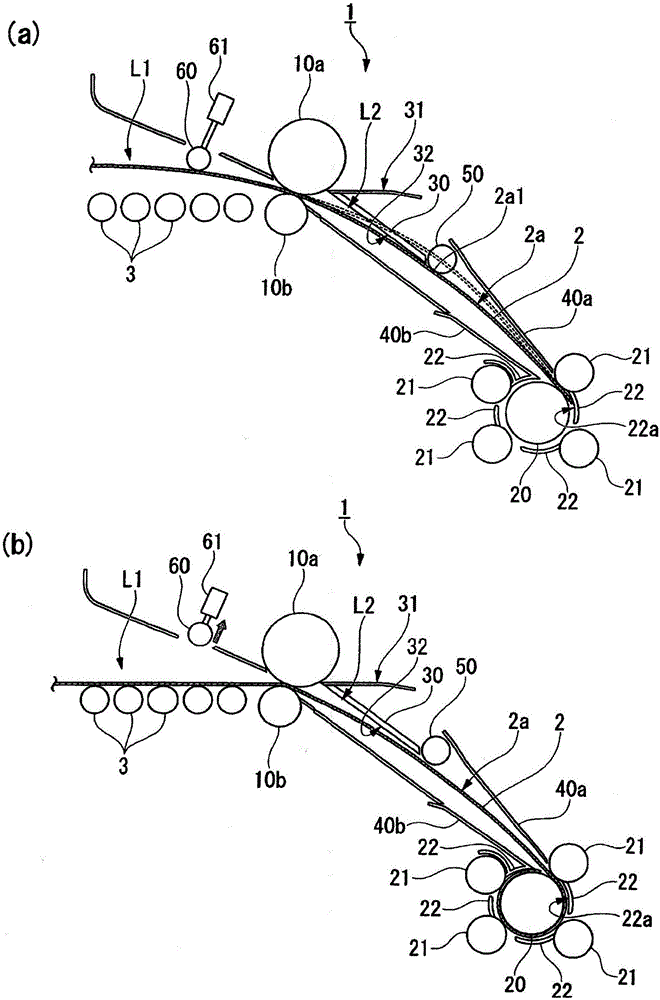

[0031] figure 1 It is a configuration diagram showing the winding device 1 according to the first embodiment of the present invention.

[0032] The coiling device 1 of this embodiment is arranged on the downstream side of a rolling mill not shown, and passes through the rolling mill and conveys the metal plate 2 along the transport path L1 (refer to the following description). figure 2 as well as image 3 ) into the coiling path L2 for coiling. The transport path L1 is formed by a plurality of transport rollers 3 arranged horizontally.

[0033] The winding device 1 includes pinch rollers 10a and 10b. The pinch rollers 10a and 10b guide the metal plate 2 conveyed along the conveyance path L1 to the winding path L2 curved from the conveyance path L1. The take-up path L2 extends obliquely downward from the transport path L1. The upper pinch roller 10a is configured so as to be able to approach and separate from the lower pinch roller 10b. The pinch roll 10a on the upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com