Strip steel coiling method, device and equipment and storage medium

A strip coiling machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low coiling accuracy, piled steel, and stuck tail of strip steel, etc., to improve automatic operation capacity, improved production quality, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

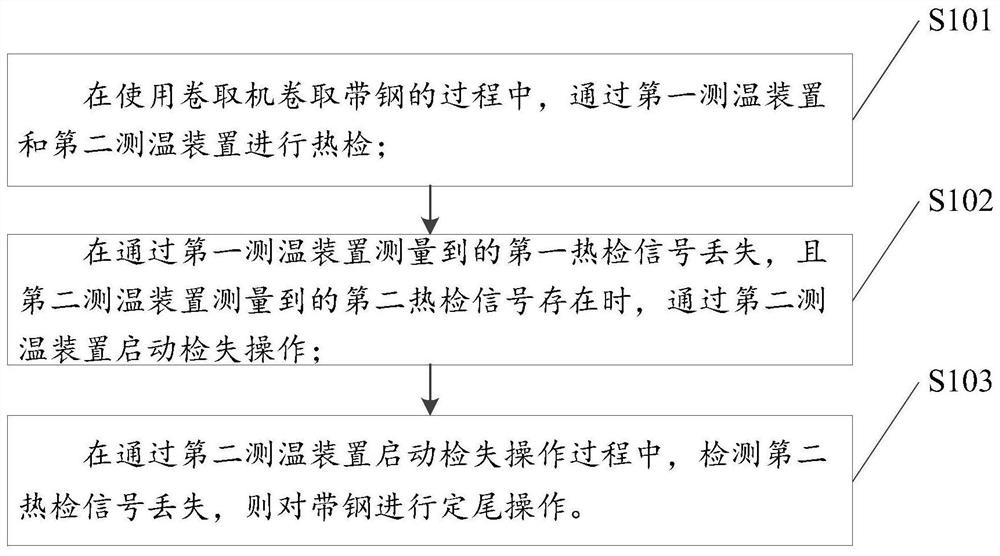

Embodiment 1

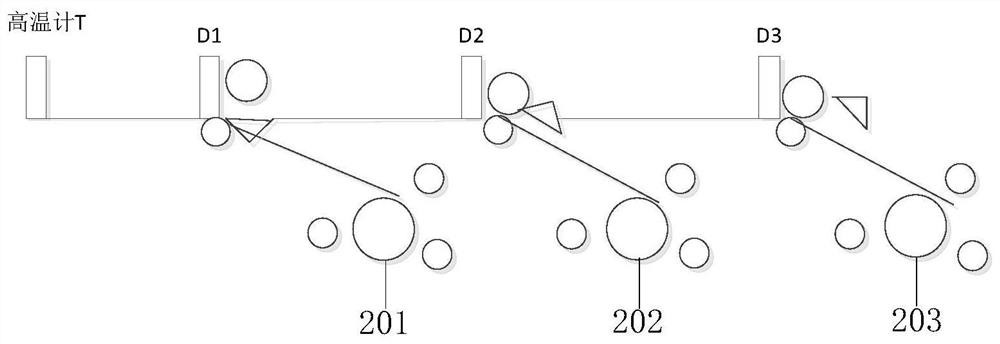

[0041] The first embodiment of the present invention provides a strip coiling method, which is applied to a coiling system. In order to illustrate the method of this embodiment more clearly, the coiling system is introduced first. The coiling system includes at least one coiler, a first temperature measuring device, a second temperature measuring device, a pinch roller and an unloading vehicle, the first temperature measuring device is arranged in front of the second temperature measuring device, and the second temperature measuring device is arranged Before the coiler. The pinch rollers are arranged on the coiler to stabilize the steel strip, so that the steel strip can be stably delivered to the coiler and avoid deformation of the steel strip. The unloading car is placed under the mandrel of the coiler and is used to load the coiled strip.

[0042] Both the first temperature measuring device and the second temperature measuring device include a heat detector (that is, a Ho...

Embodiment 2

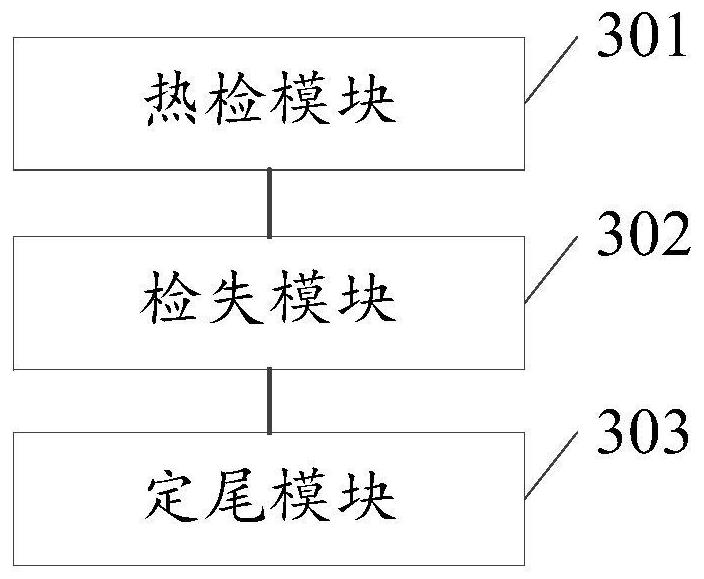

[0086] Based on the same inventive concept, the second embodiment of the present invention also provides a strip coiling device, such as image 3 As shown, it is applied to a coiling system, and the coiling system includes a coiling machine, a first temperature measuring device and a second temperature measuring device, and the first temperature measuring device is arranged in front of the second temperature measuring device, so The second temperature measuring device is arranged before the coiler; the device includes:

[0087] A heat detection module 301, configured to perform heat detection through the first temperature measuring device and the second temperature measuring device during the process of coiling the steel strip with the coiler;

[0088] The loss detection module 302 is configured to, when the first thermal detection signal measured by the first temperature measuring device is lost and the second thermal detection signal measured by the second temperature measur...

Embodiment 3

[0108] Based on the same inventive concept, the third embodiment of the present invention also provides a computer device, such as Figure 4 As shown, it includes a memory 404, a processor 402 and a computer program that is stored on the memory 404 and can run on the processor 402. When the processor 402 executes the program, any one of the above-mentioned strip coiling methods is realized. method steps.

[0109] Among them, in Figure 4 In, bus architecture (represented by bus 400), bus 400 may include any number of interconnected buses and bridges, bus 400 will include one or more processors represented by processor 402 and various types of memory represented by memory 404 circuits linked together. The bus 400 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. The bus interface 406 provides an interface between the bus 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com