Patents

Literature

40results about How to "Improve automation capabilities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

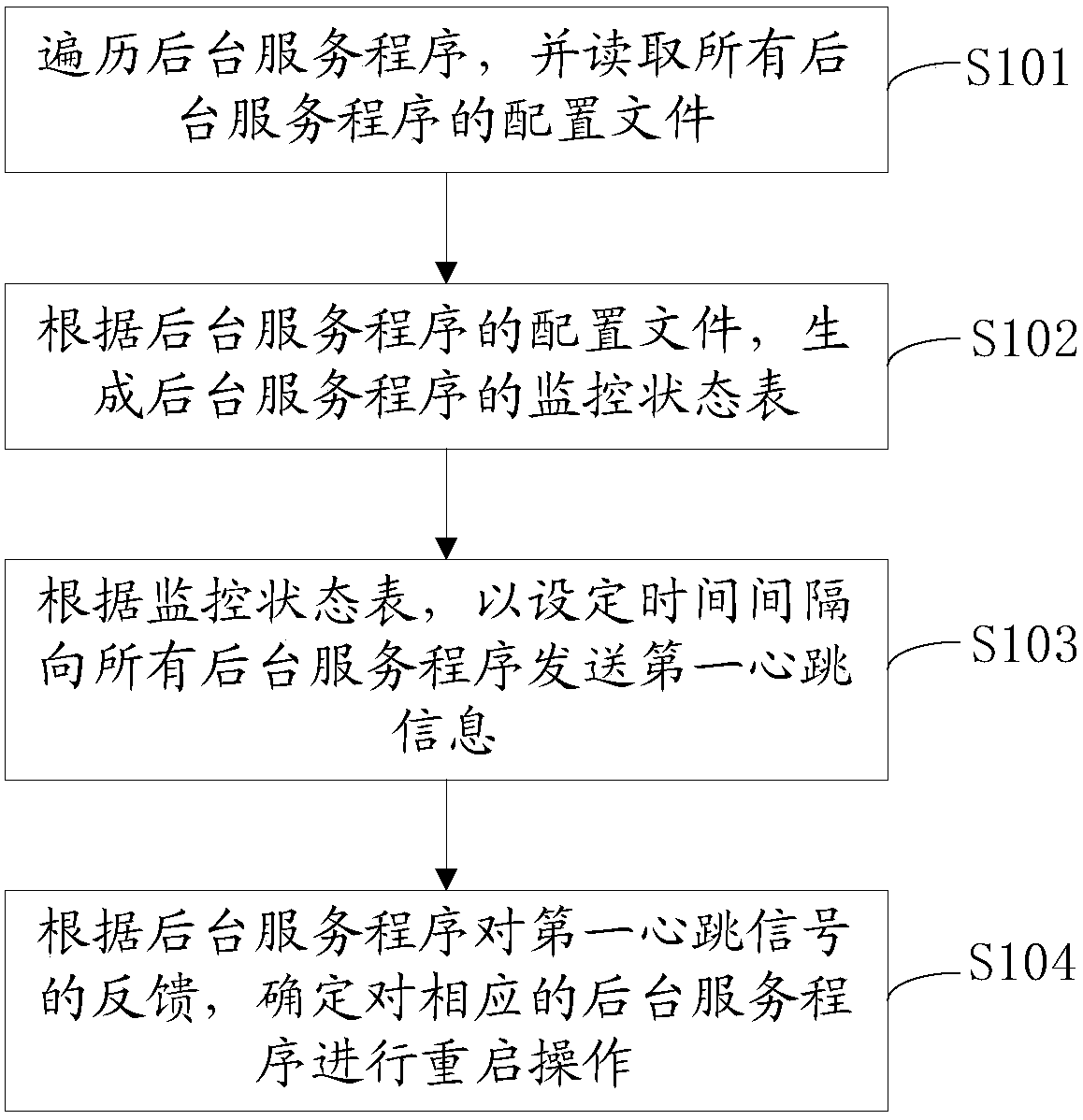

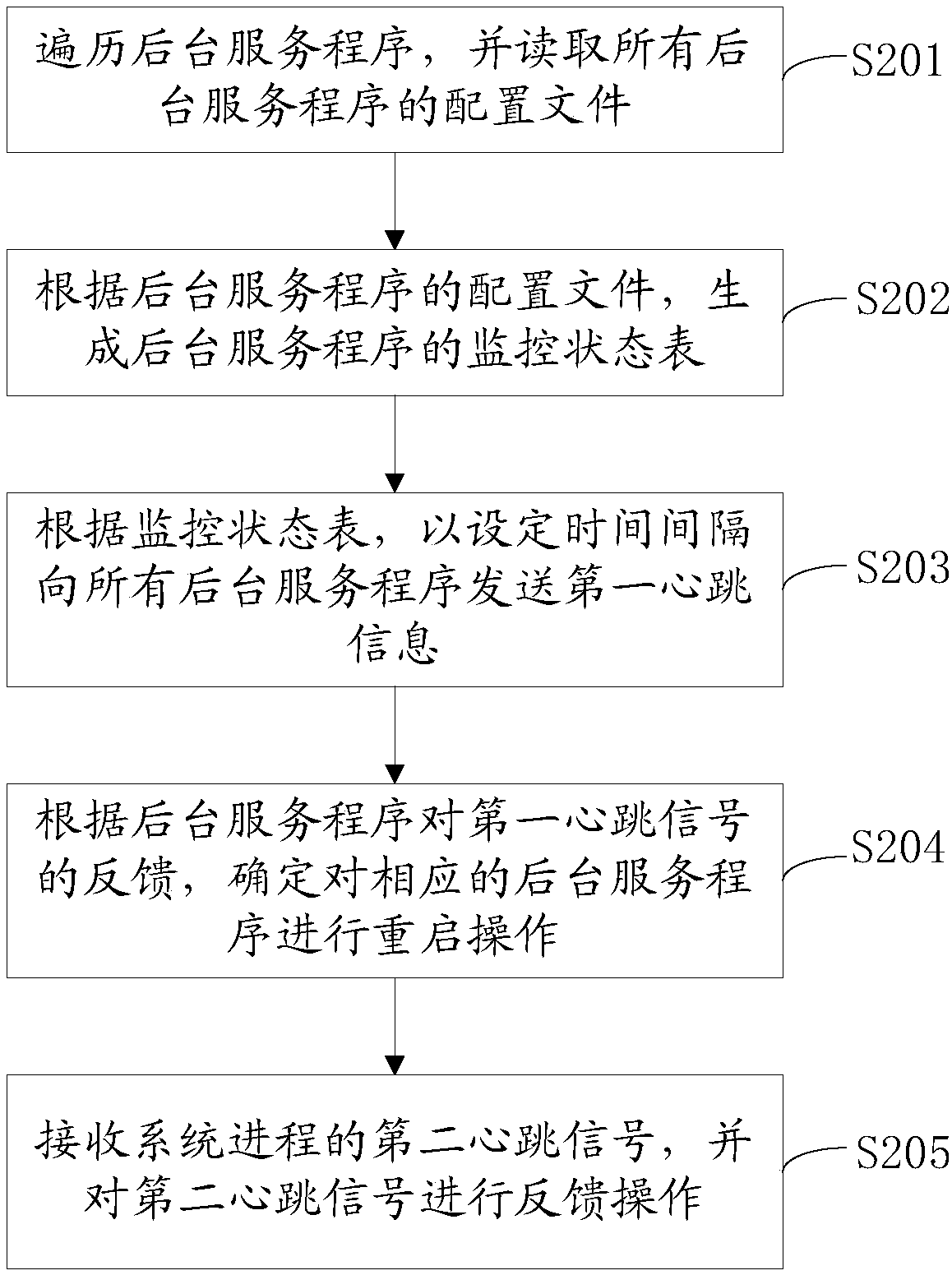

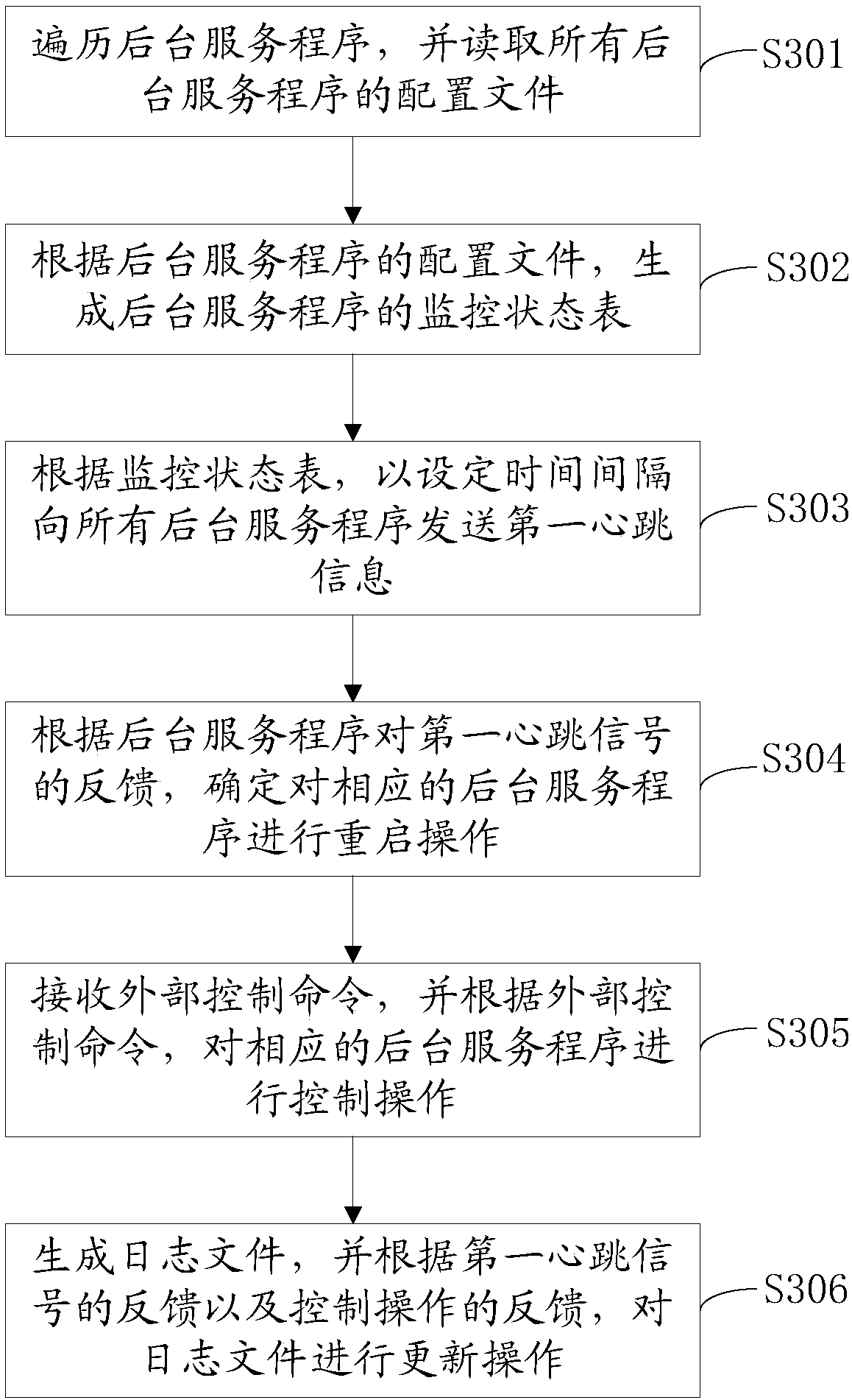

Background program monitoring method and monitoring apparatus

ActiveCN108427616AThe judgment result is accurateImprove automation capabilitiesHardware monitoringMonitoring statusSetting time

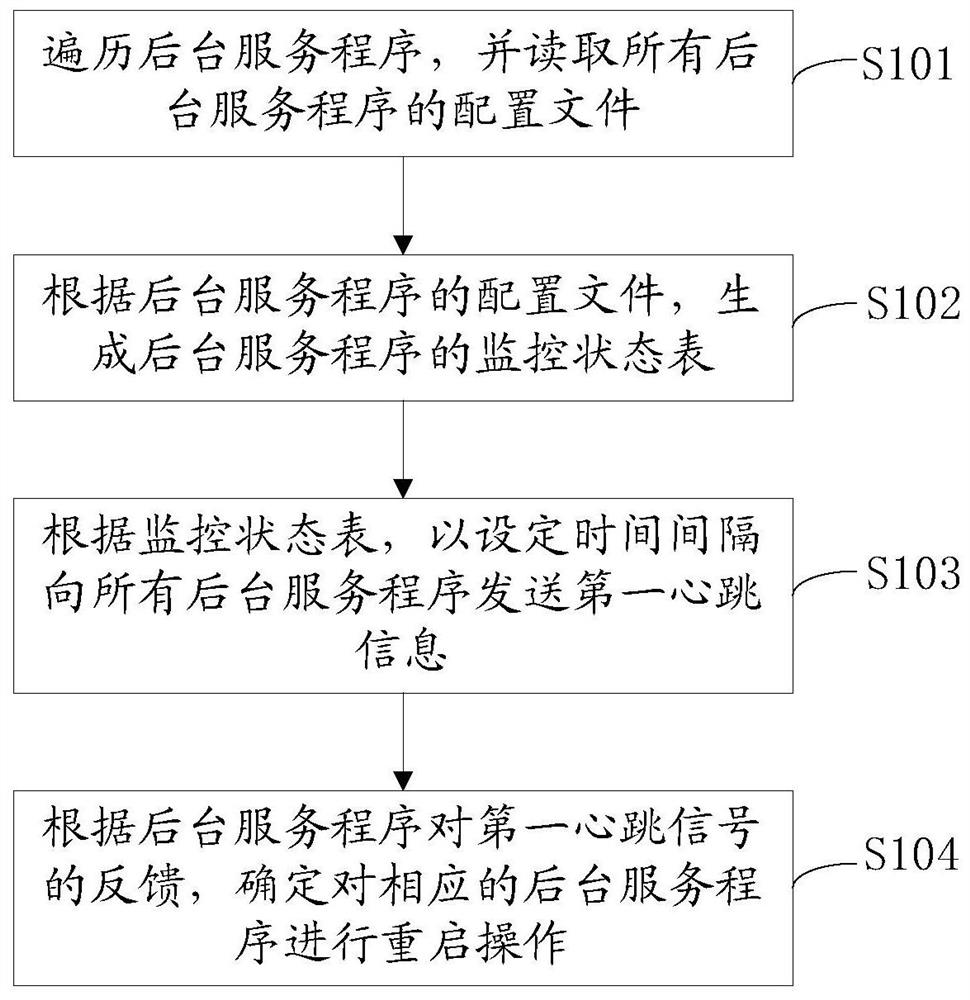

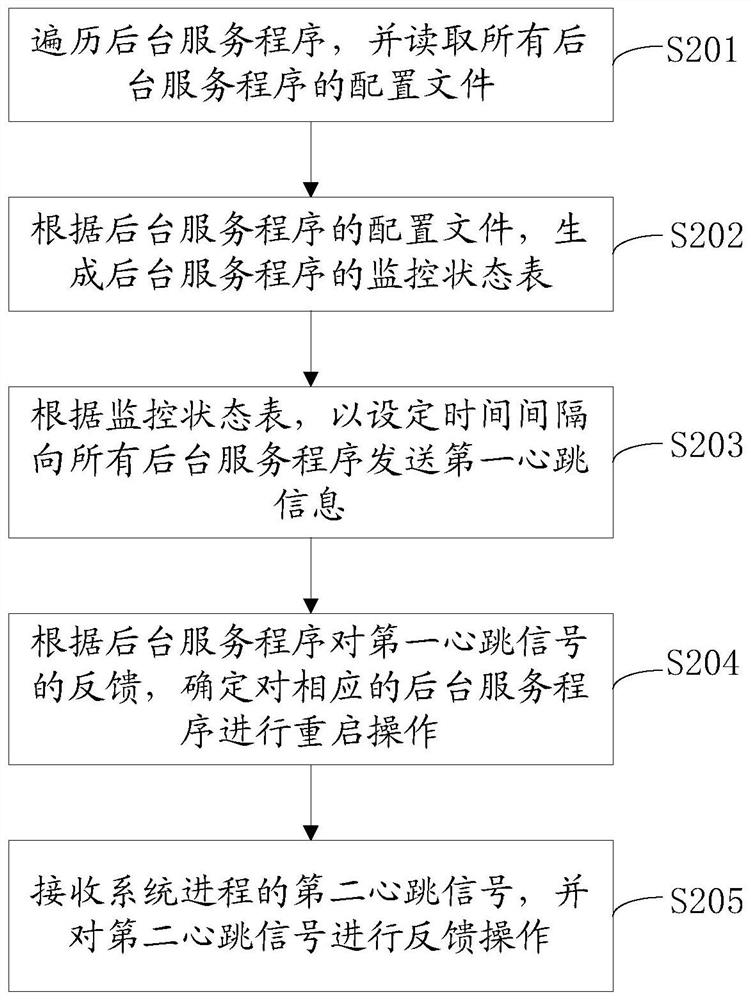

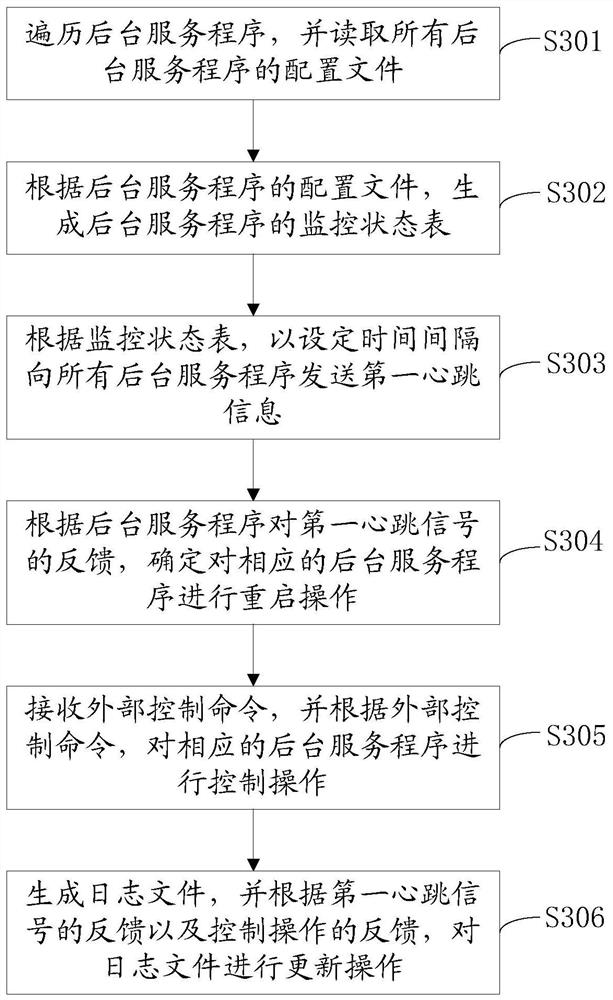

The invention provides a background program monitoring method. The method comprises the steps of traversing background service programs, and reading configuration files of all the background service programs; according to the configuration files of the background service programs, generating a monitoring state table of the background service programs; according to the monitoring state table, sending a first heartbeat signal to all the background service programs by a set time interval; and according to feedbacks of the background service programs to the first heartbeat signal, determining to perform restarting operation on the corresponding background service programs. The invention furthermore provides a background program monitoring apparatus. According to the background program monitoring method and the background program monitoring method apparatus, whether the background service programs run normally or not by sending the heartbeat signal to the background service programs, so that a judgment result is more accurate, the automatic running capability of a background program monitoring process can be improved, and the operation of manually performing state confirmation of the background service programs is avoided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

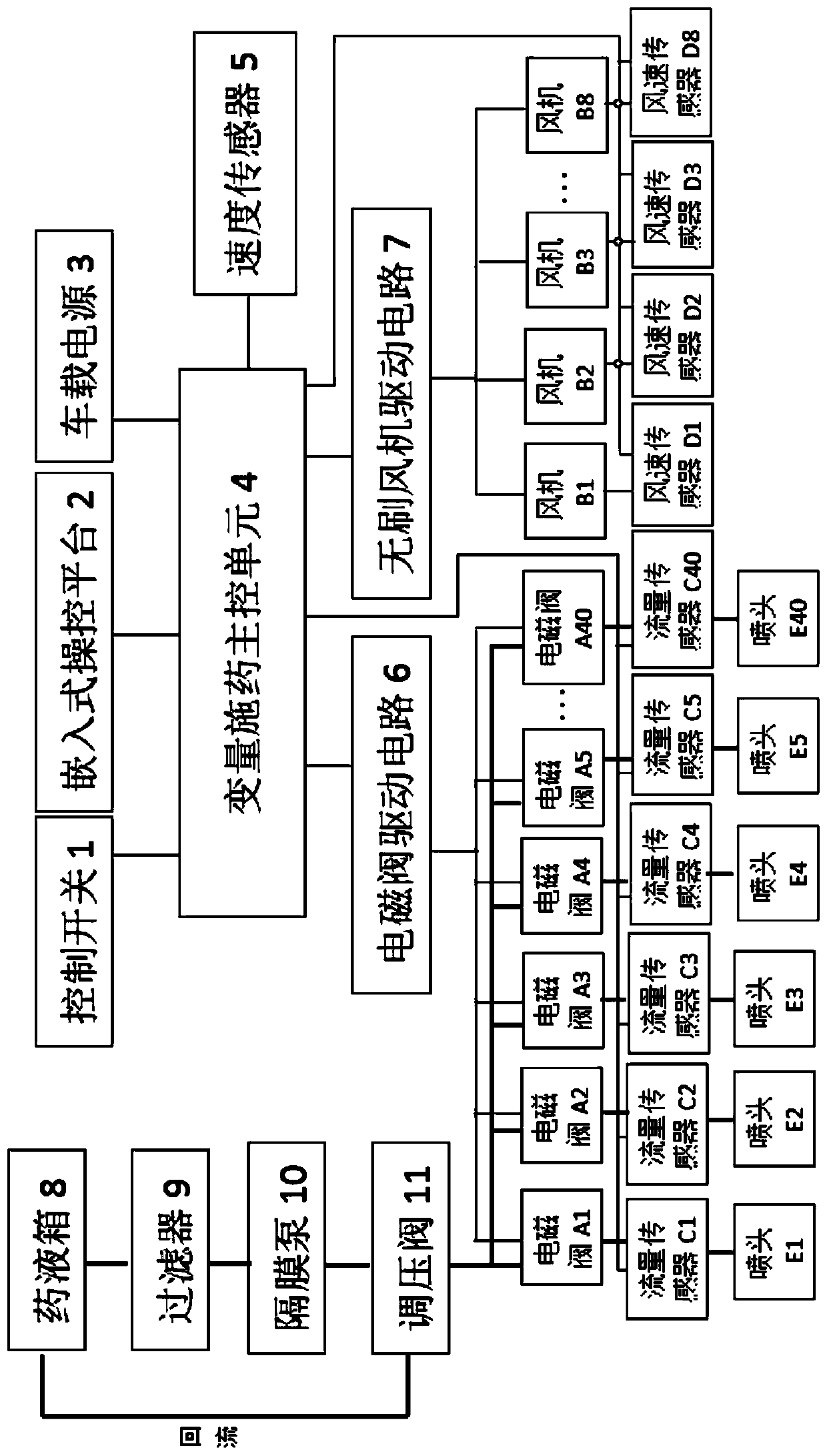

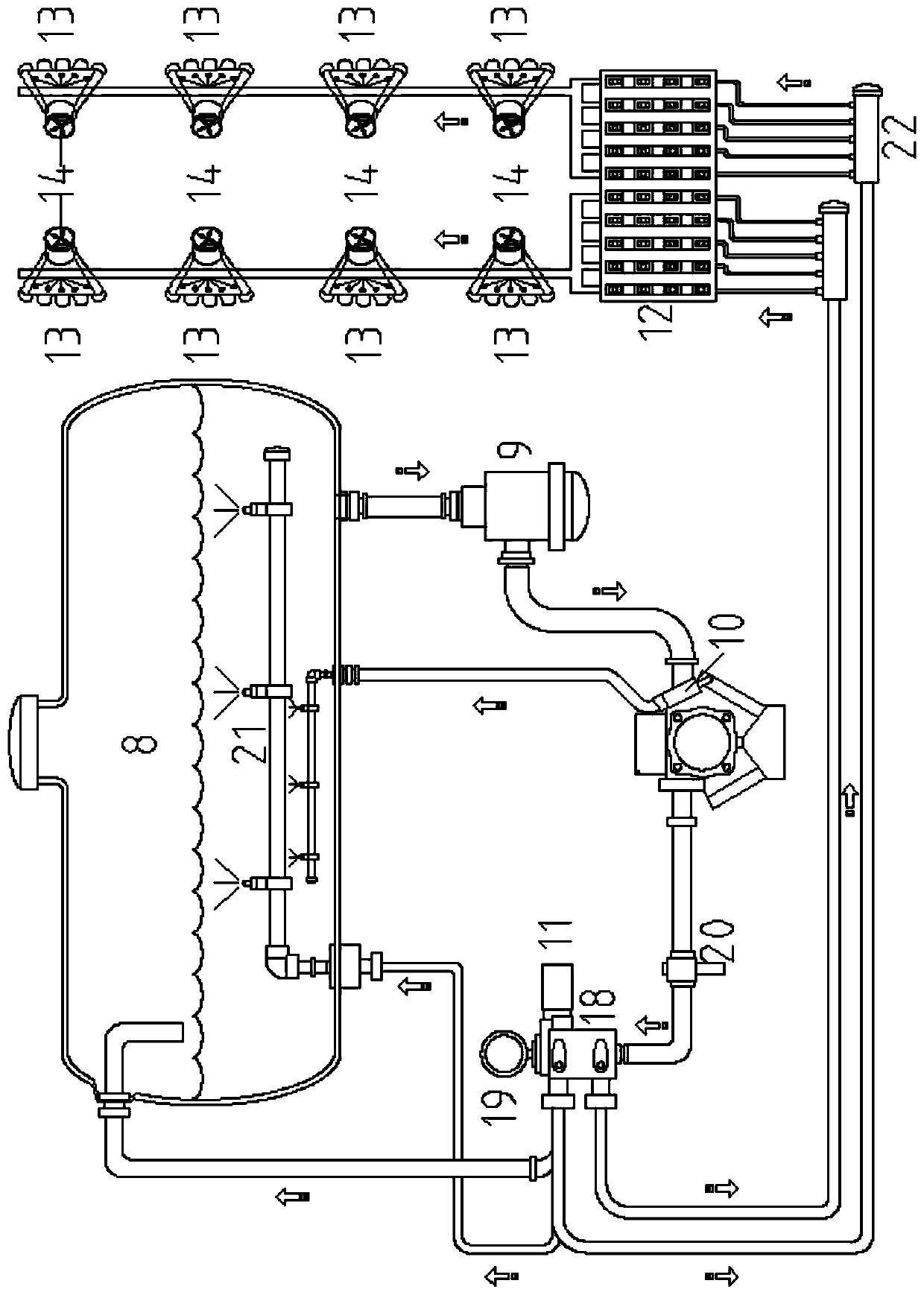

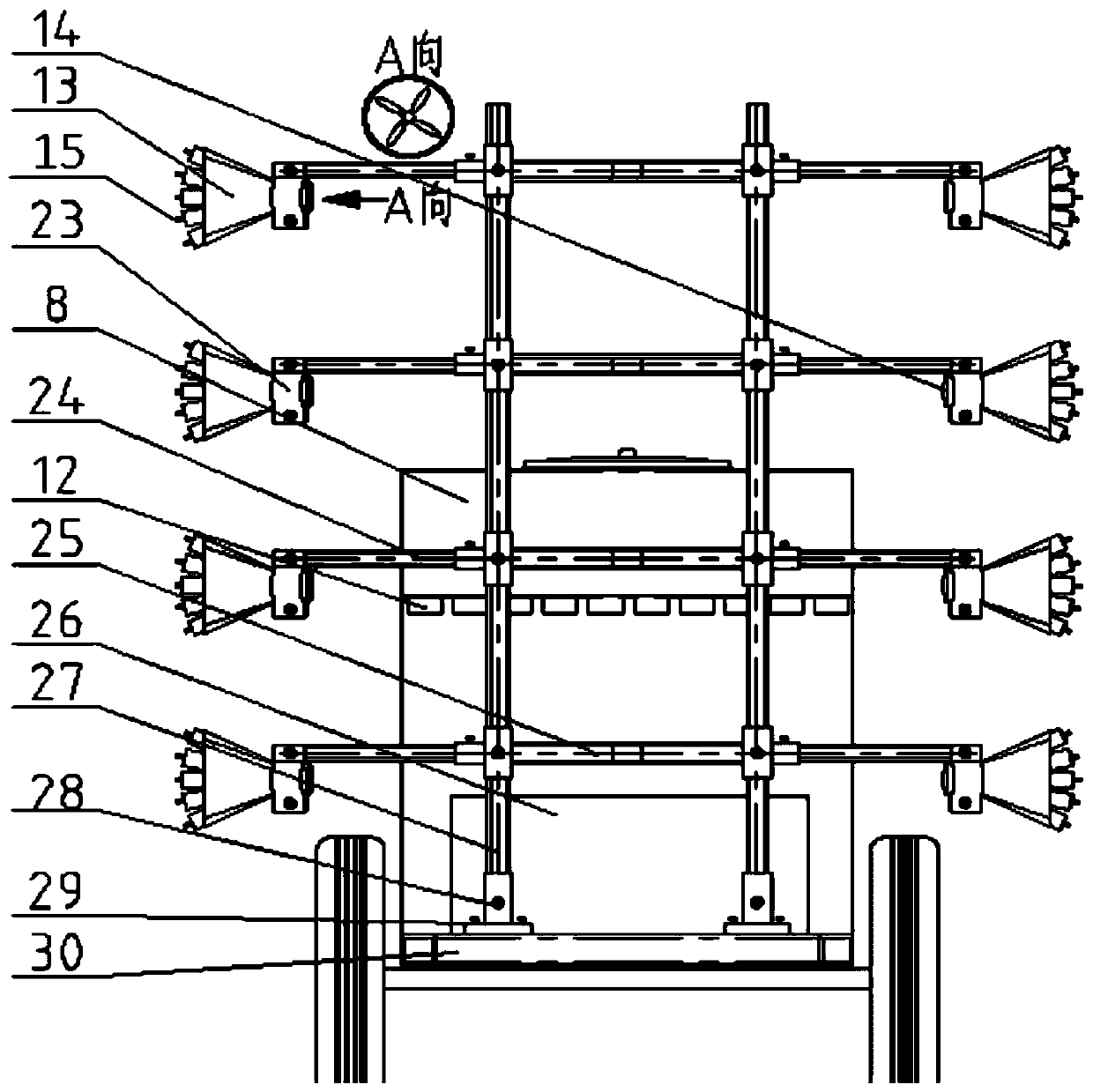

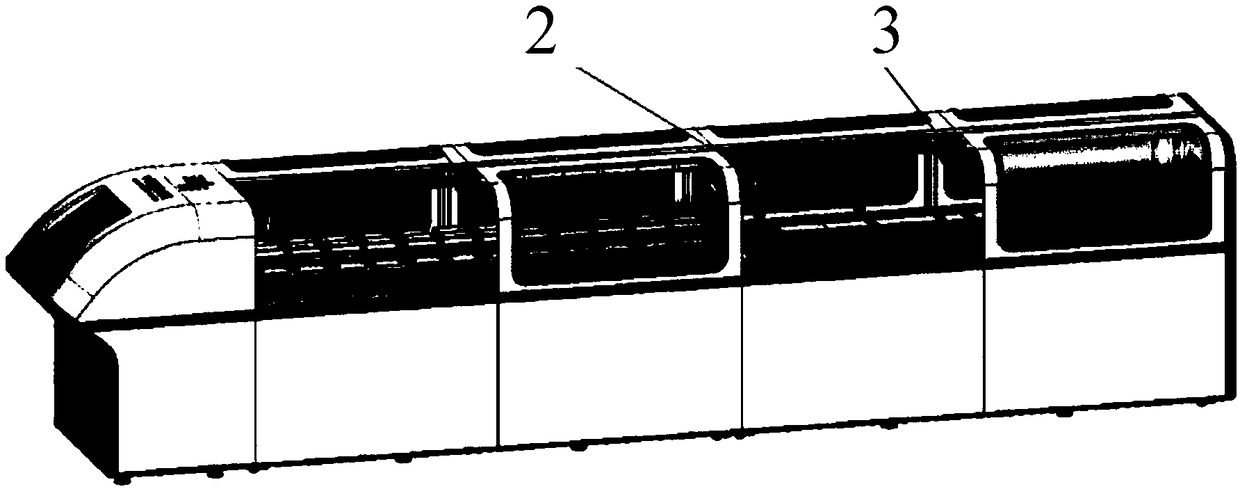

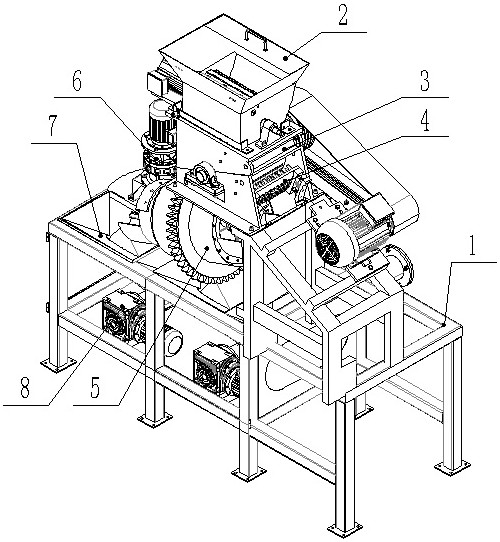

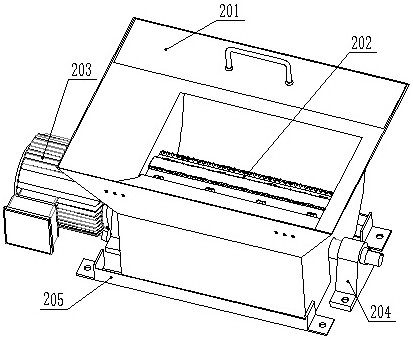

Method for automatically adjusting flow rate of sprinkler of profiling variable spraying system of spraying machine

PendingCN111084173AExtended working hoursKnow the dosage in real timeInsect catchers and killersControl signalAgricultural engineering

The invention belongs to the field of agricultural plant protection machinery, in particular to a method for automatically adjusting the flow rate of a sprinkler of a profiling variable spraying system of a spraying machine. The invention aims to provide a method for automatically adjusting the flow rate of the sprinkler of the profiling variable spraying system of the spraying machine. PWM control signals are adopted to adjust the flow rate of the sprinkler and the air flow of a fan which is used for assisting transportation of sprayed droplets, the flow rate of the sprinkler and the air flowof the fan are set according to the type of a tree crown, and a spray bar can be adjusted according to the growth trend of the crown so as to achieve profiling spraying, so that the utilization rateof pesticide is improved effectively, the uniformity of deposition of a chemical liquid on a canopy is improved, and environmental pollution and personal injury which are caused by the drifting pesticide are reduced in the spraying process. The method has the characteristics of good applicability, high working efficiency, fast response to a control system and precise application of pesticide, andpromotion of pesticide-saving technologies is facilitated.

Owner:CHINA AGRI UNIV

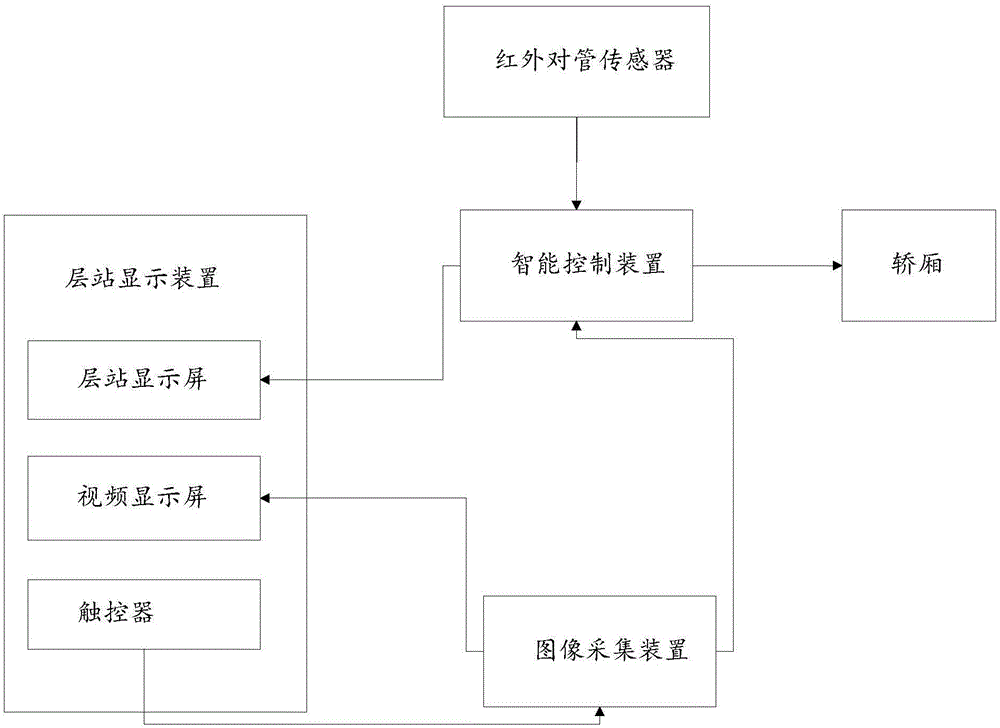

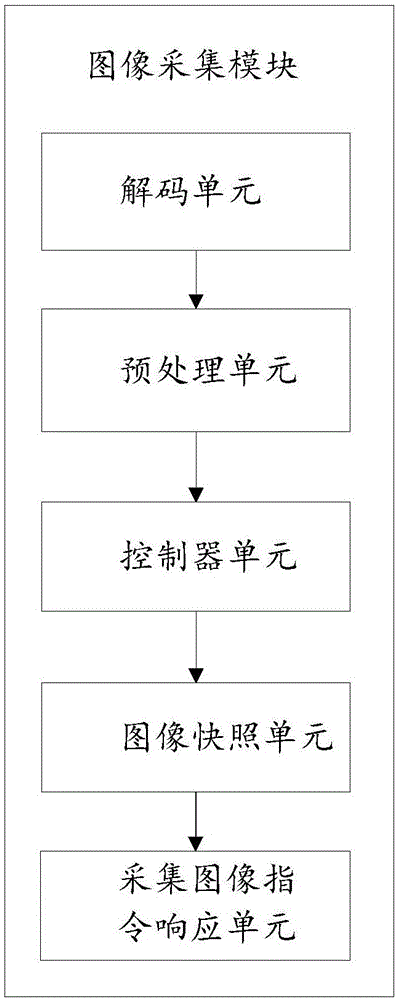

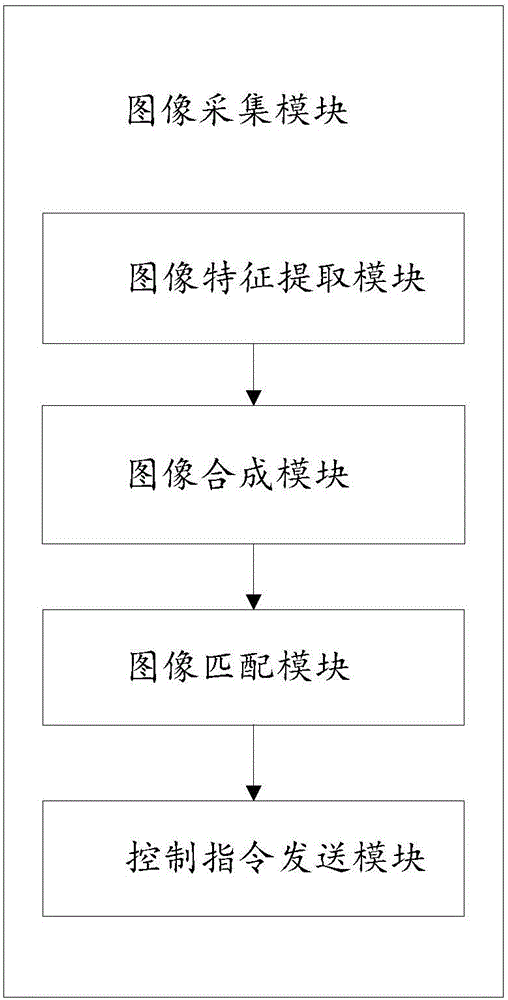

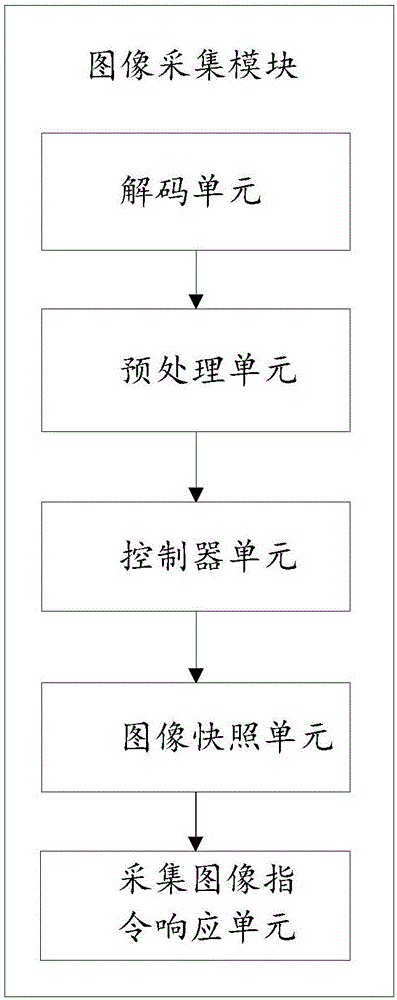

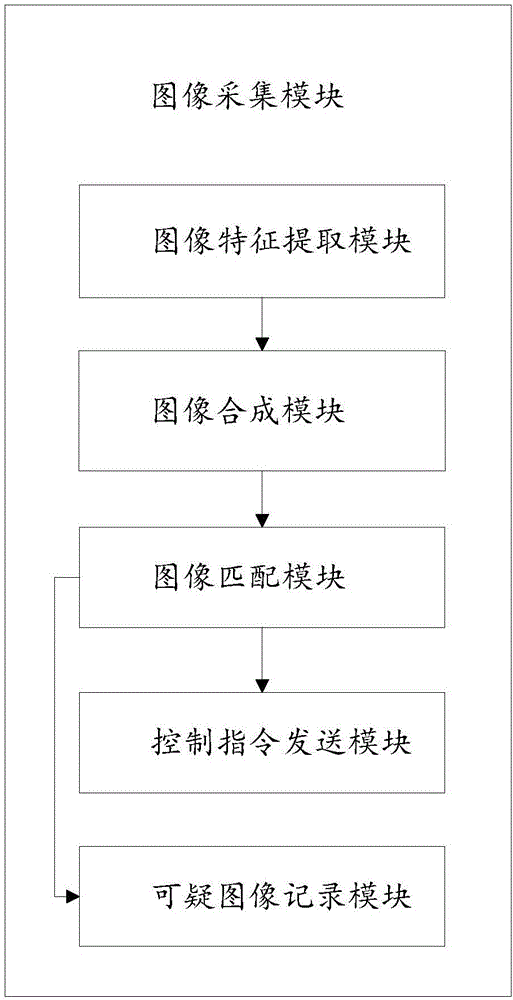

Multifunctional intelligent elevator system and control method

ActiveCN106829662AImprove automation capabilitiesSave the actions of destination designation and card swiping attendanceElevatorsAutomatic judgementElevator system

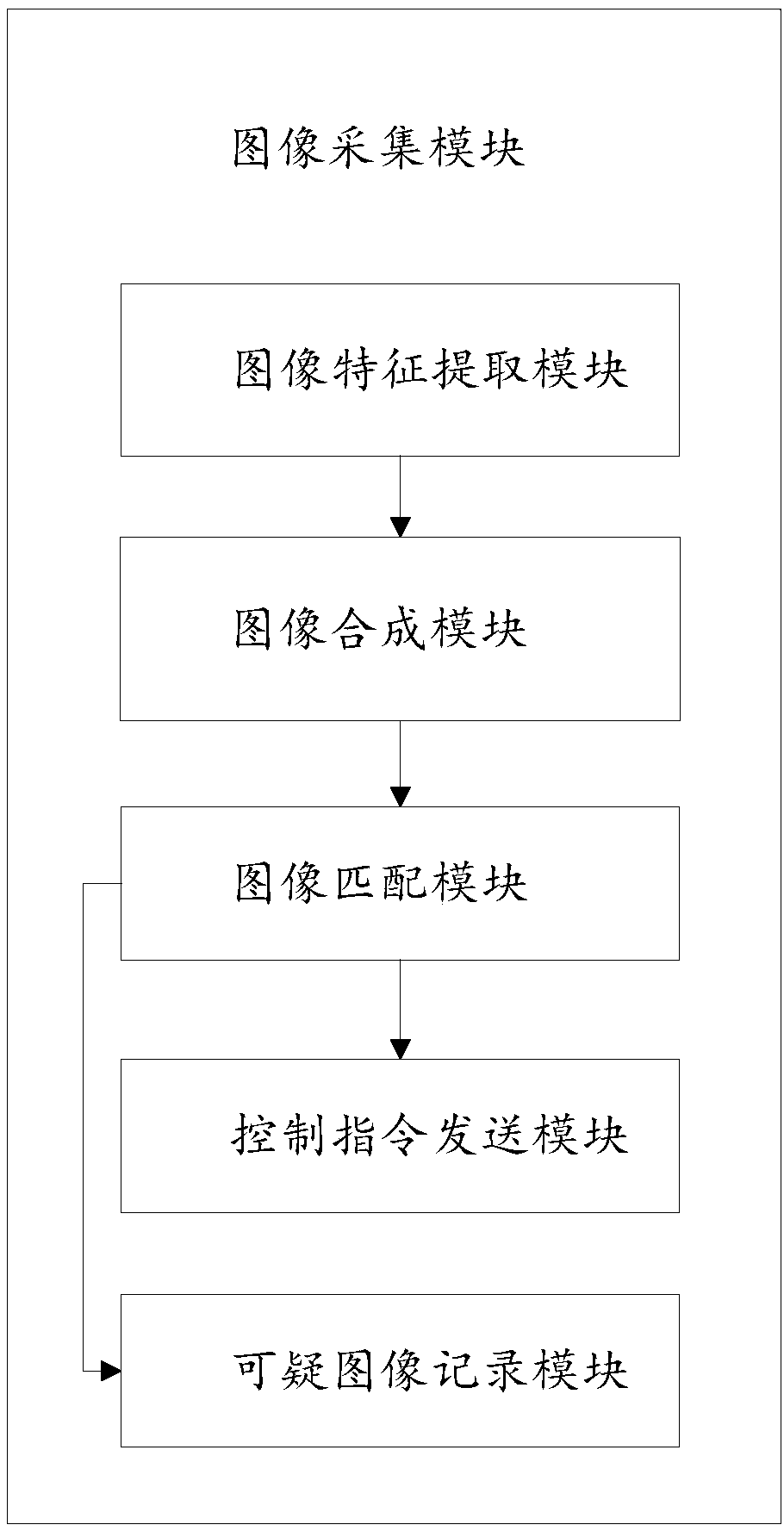

The invention provides a multifunctional intelligent elevator system and a control method. User images are acquired through the shooting of a user video and the response to user issued image acquisition instructions, and according to the user images matched with the acquired images, user identity is thus confirmed; according to the user identity,a target floor whichthe user needs to visit is obtained, control instructionsare automatically sent to a lift car so as to control the lift car to move to the target floor, user operations are spared, and the function of automatically judging user destination is achieved. Furthermore, through the method of obtaining the user image time of the user collection and according to the generated attendance records of thesaid time, automatic generations of the attendance records are achieved, and the generation of attendance records and the automatic judgement of user destination are automatically completed through image recognitions, the automatic operation capacity of an elevator is significantly enhanced, and the designation of user routine destinationsand theaction of card attendance are spared,and user experience is enhanced.

Owner:北菱电梯股份有限公司

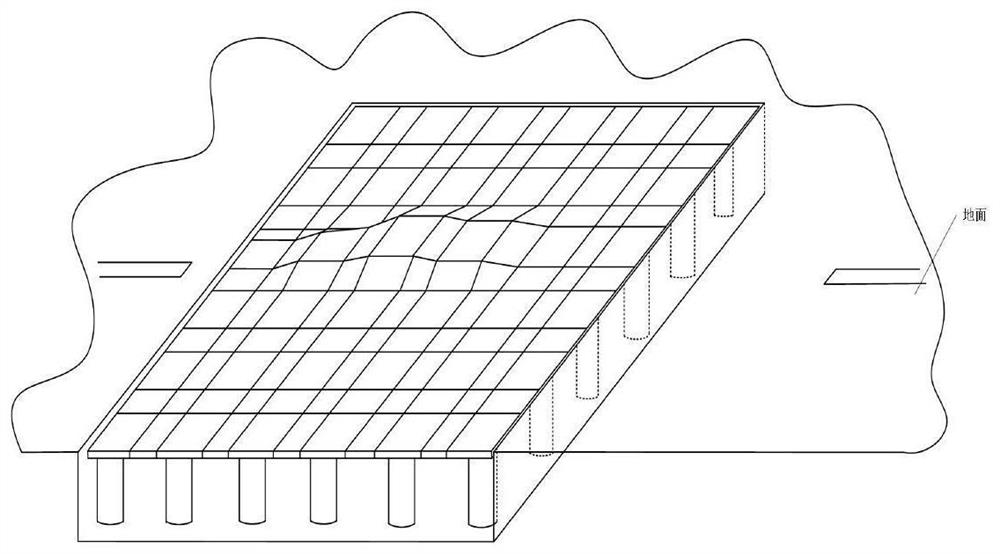

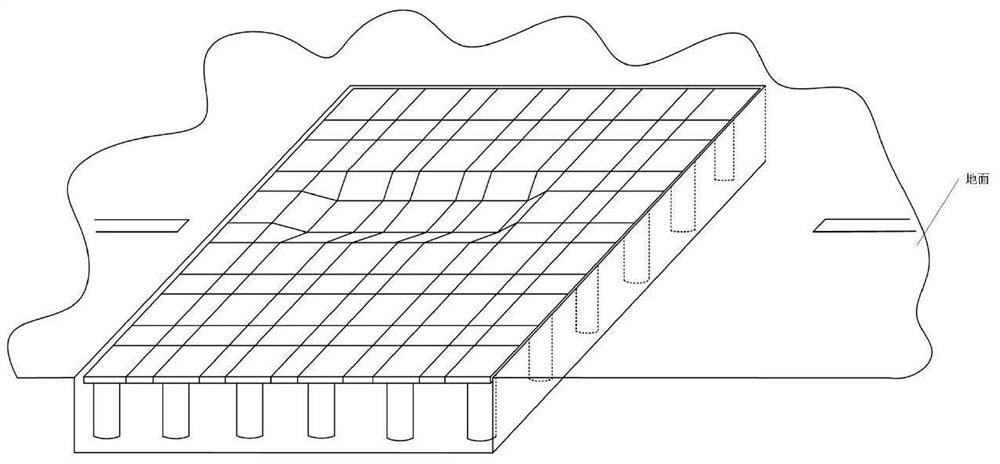

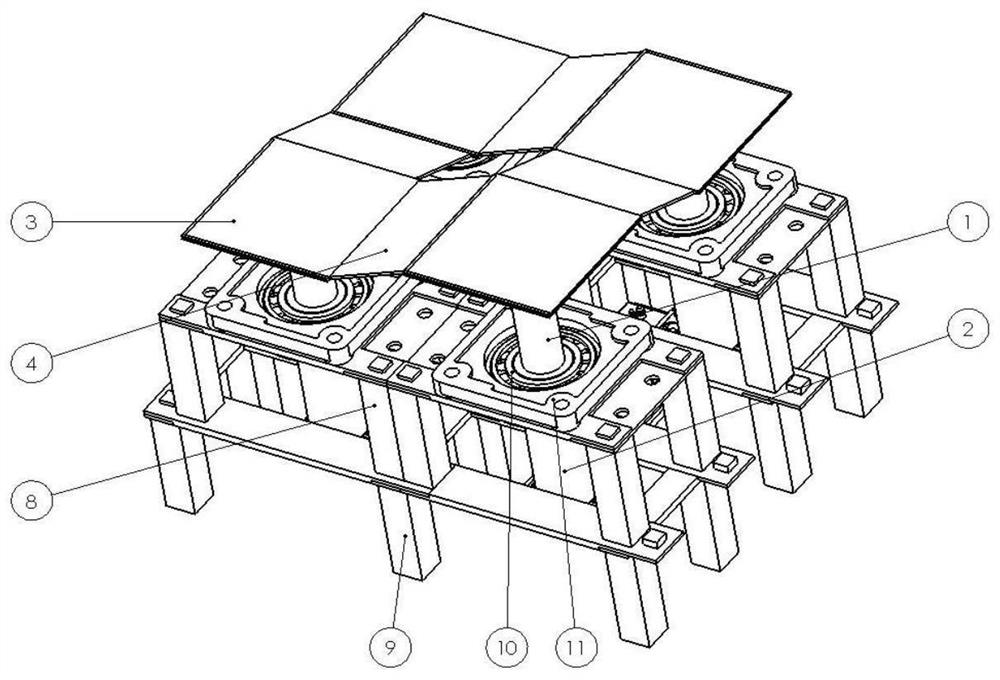

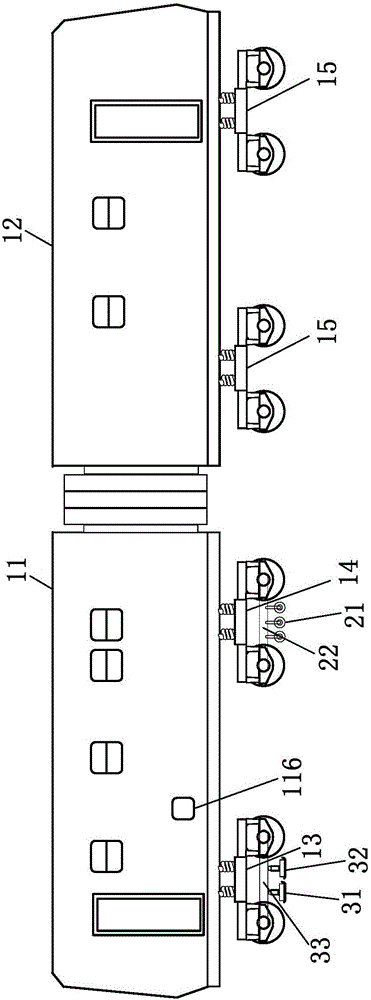

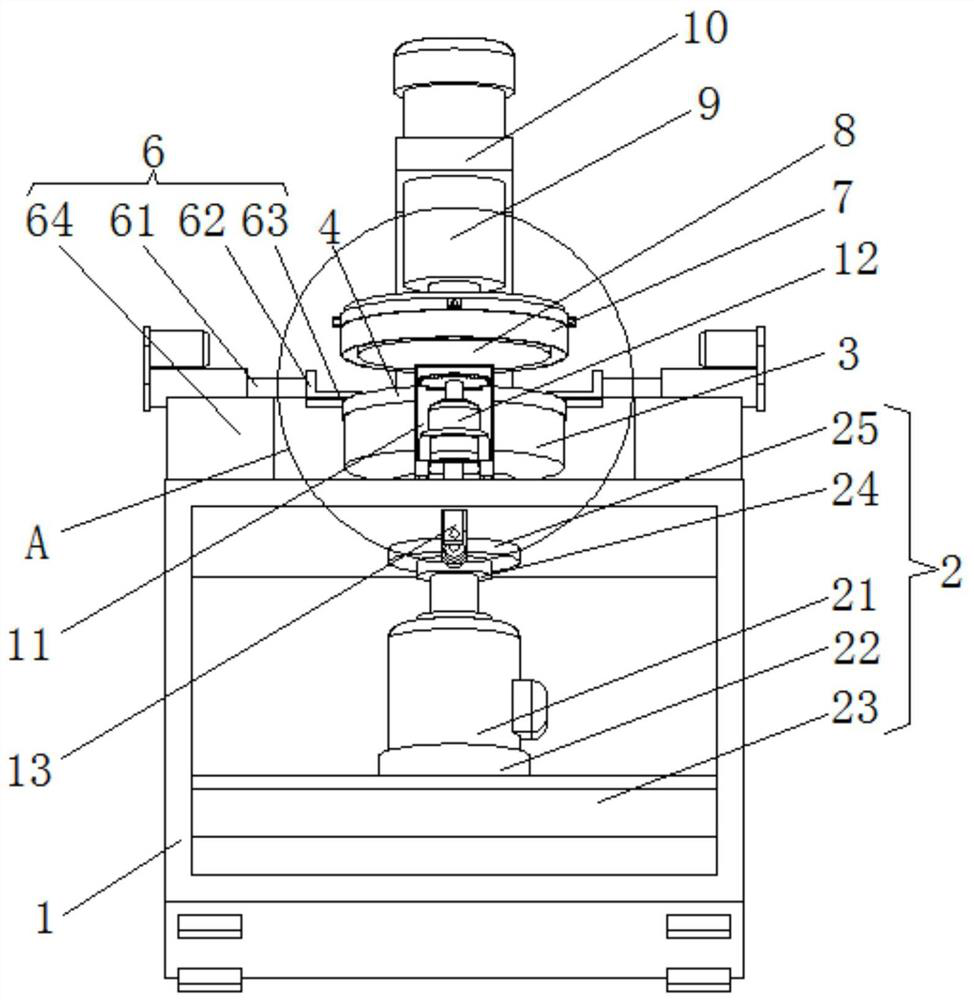

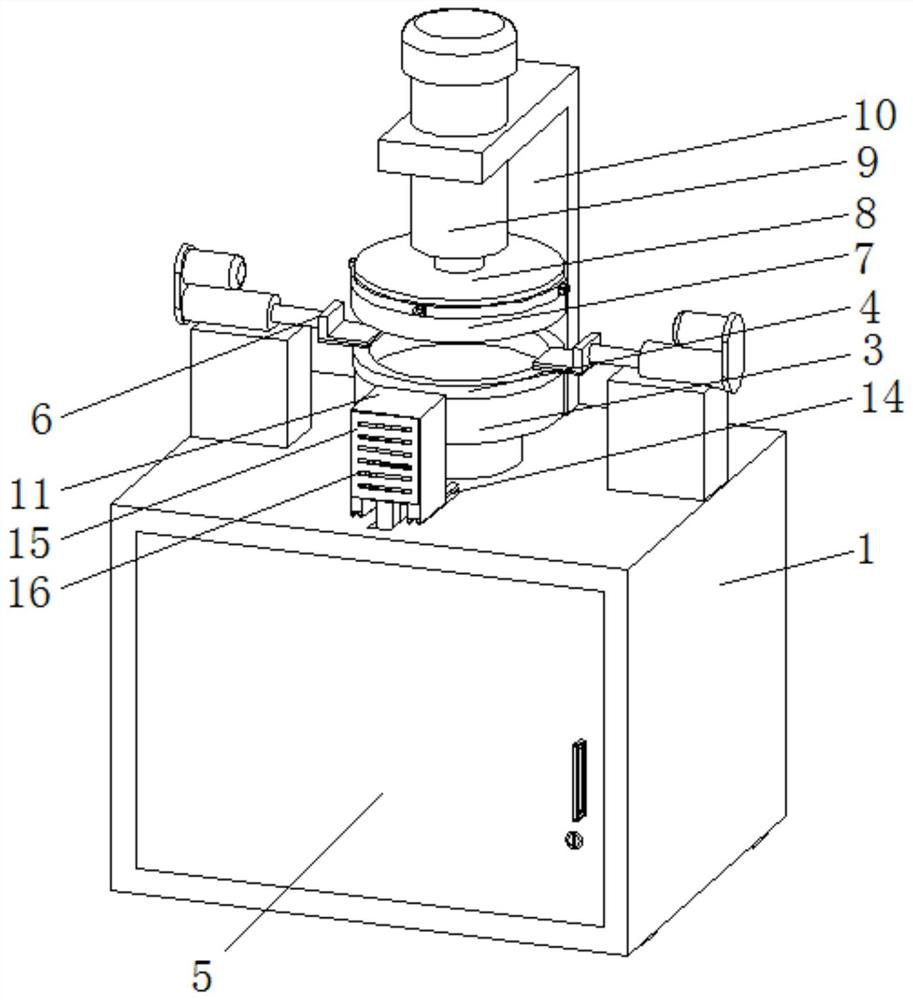

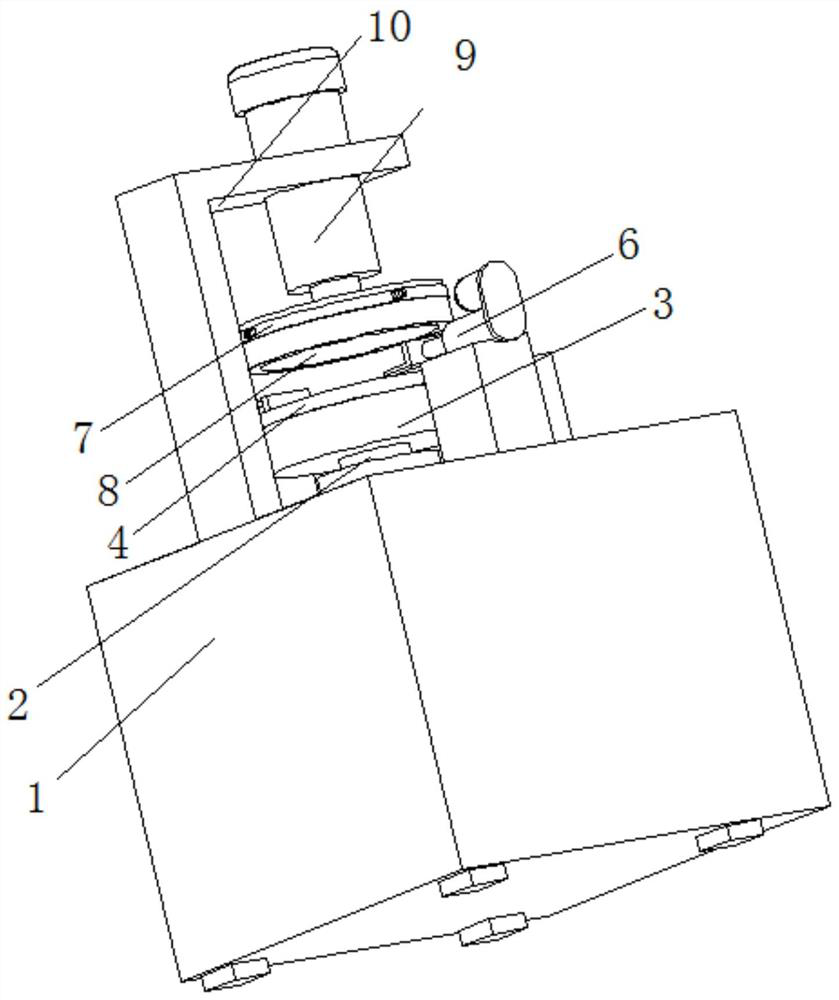

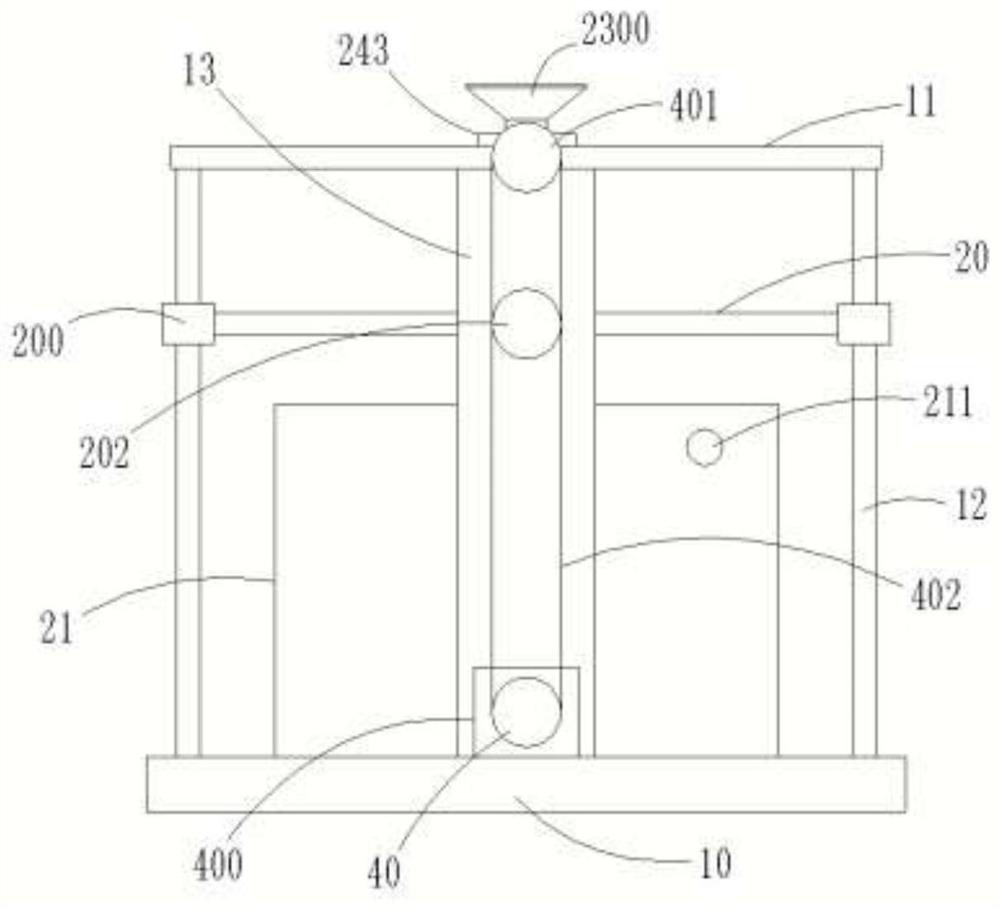

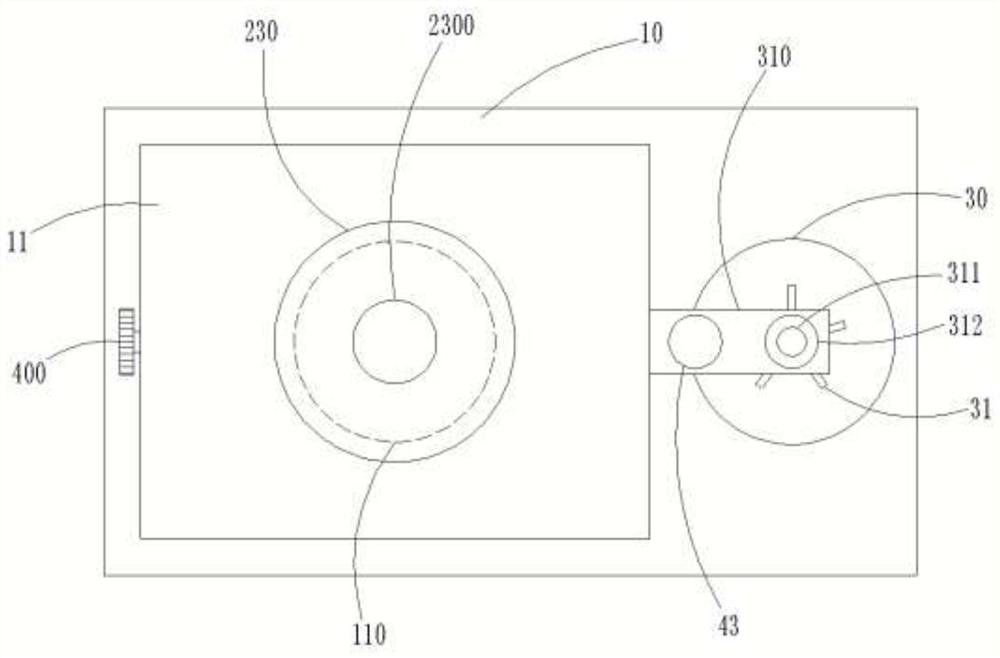

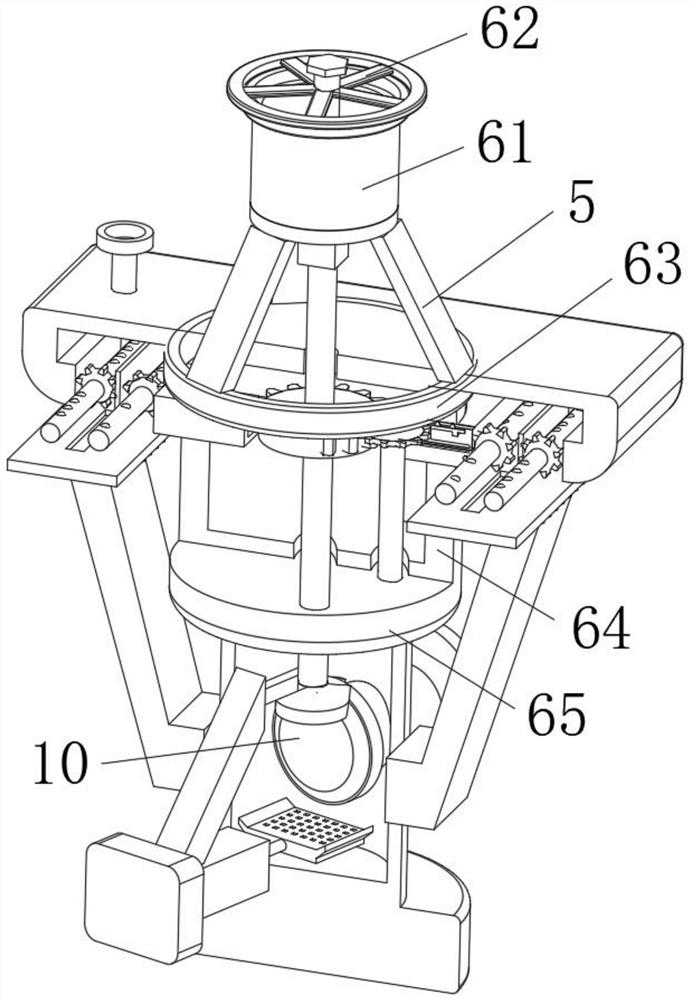

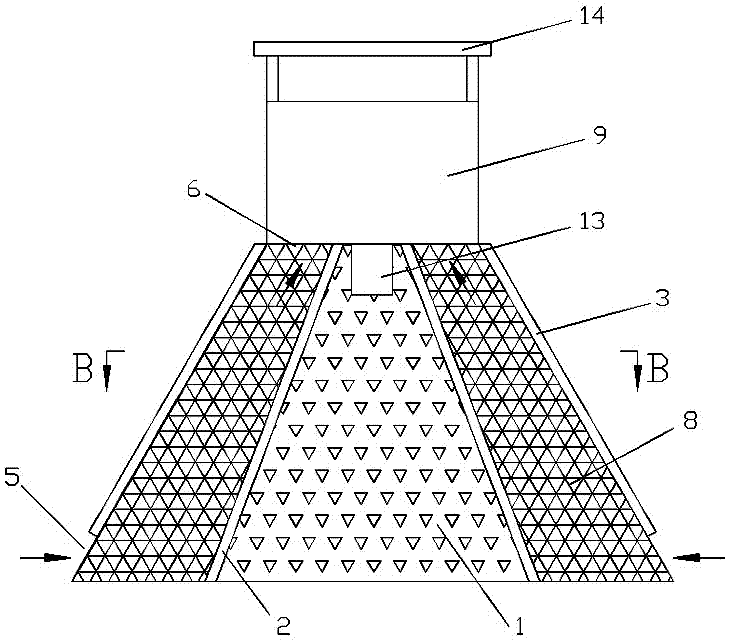

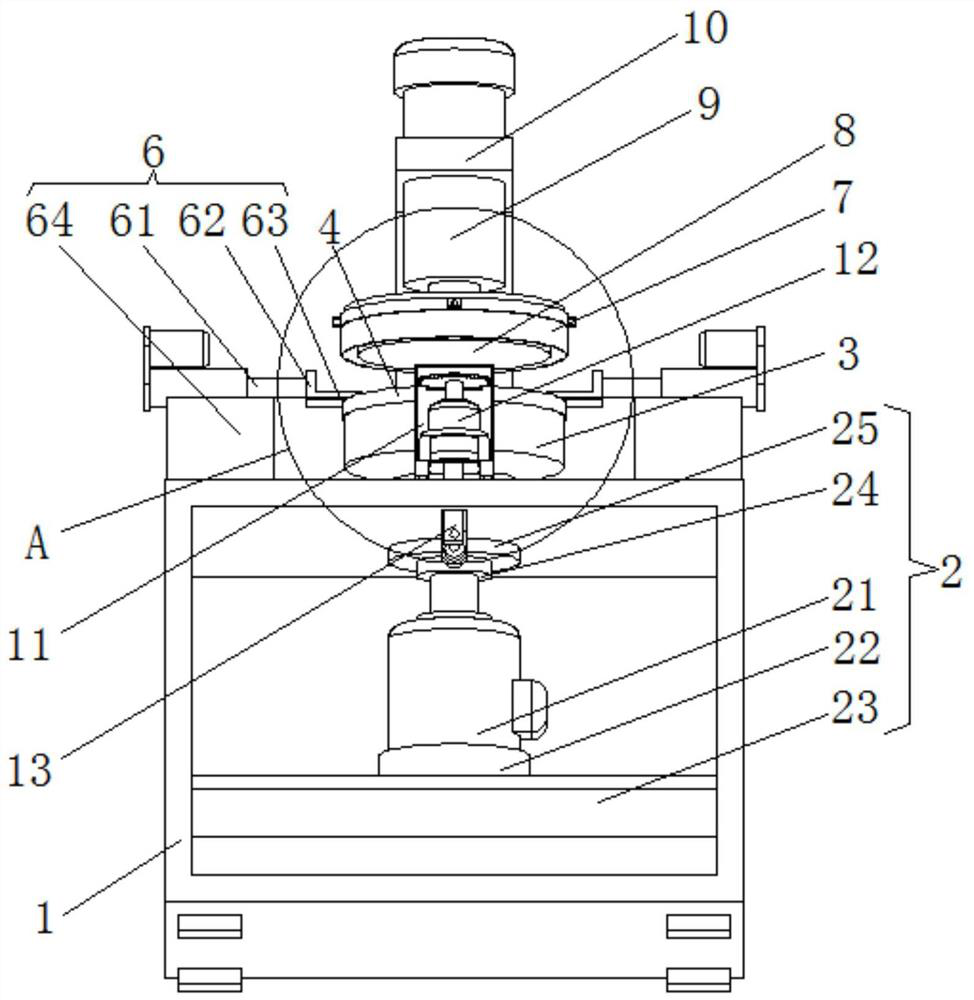

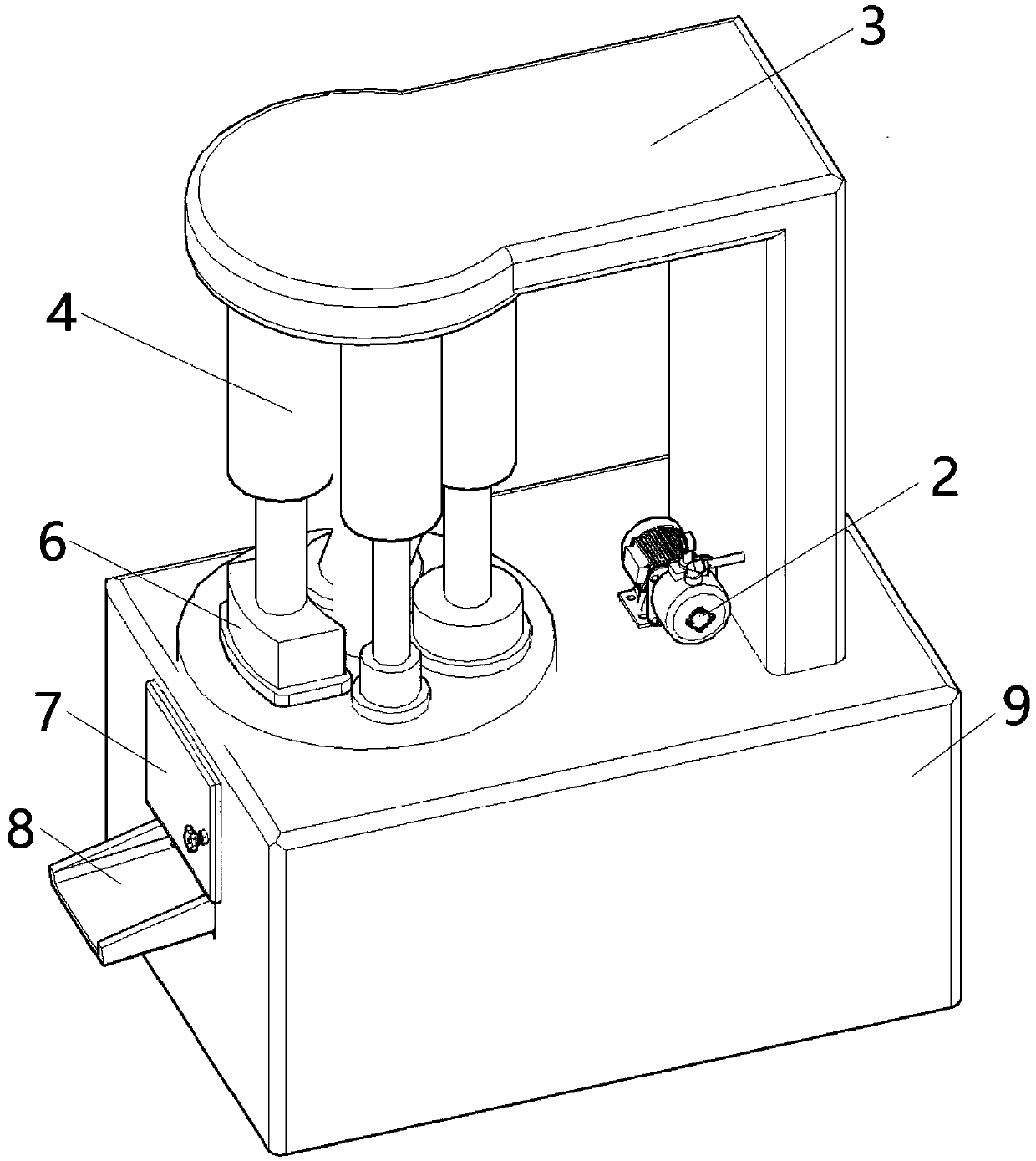

Simulation device and device set capable of adjusting and controlling concave-convex degree of road surface

ActiveCN112444405AImprove automation capabilitiesImprove drive test efficiencyVehicle testingGear wheelRoad surface

The invention discloses a simulation device and device set capable of adjusting and controlling the concave-convex degree of a road surface belongs to the field of automobile testing, and aims to provide traffic road scenes of various road surfaces with different concave-convex degrees in automobile driving simulation. A bearing is mounted in a bearing seat supported by a support frame; the circumferential surface of one section of the top end of a sleeve is installed in an inner ring of the bearing; the inner circumferential surface of the sleeve is provided with internal threads; the circumferential surface of one section of the bottom end of the sleeve is provided with a gear ring formed by teeth meshed with a gear; a road plate is laid on the top end face of a threaded supporting column; external threads matched with the internal threads of the sleeve are arranged on the periphery of the threaded supporting column; the sleeve rotates in two opposite directions to adjust the depth of the threaded supporting column located in the sleeve due to threaded connection, so that the height of the threaded supporting column between the bearing seat and the road plate is adjusted. As manydrive test environments as possible can be provided for driverless automobiles.

Owner:DALIAN NATIONALITIES UNIVERSITY

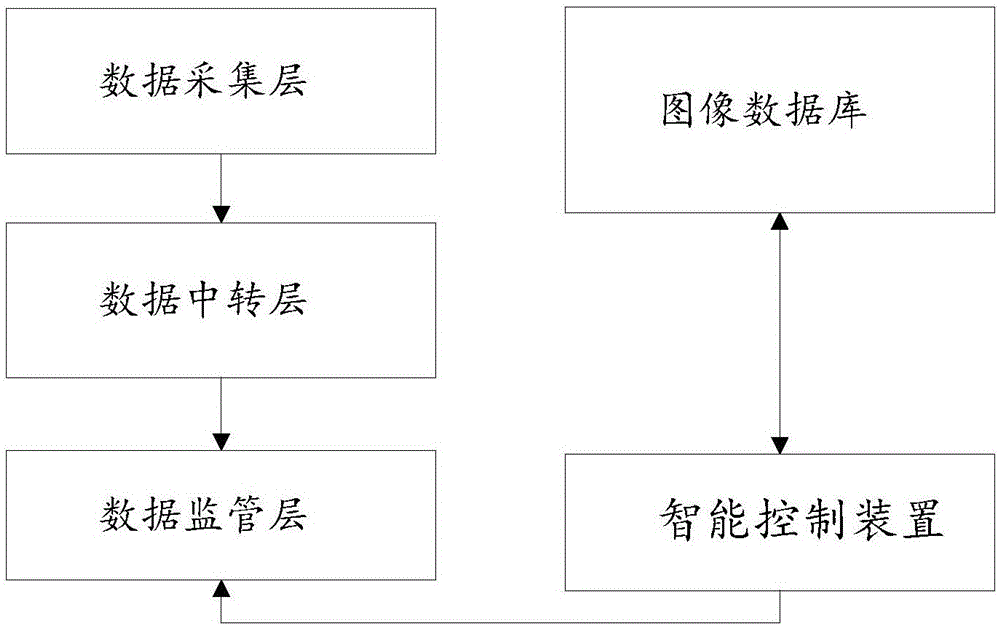

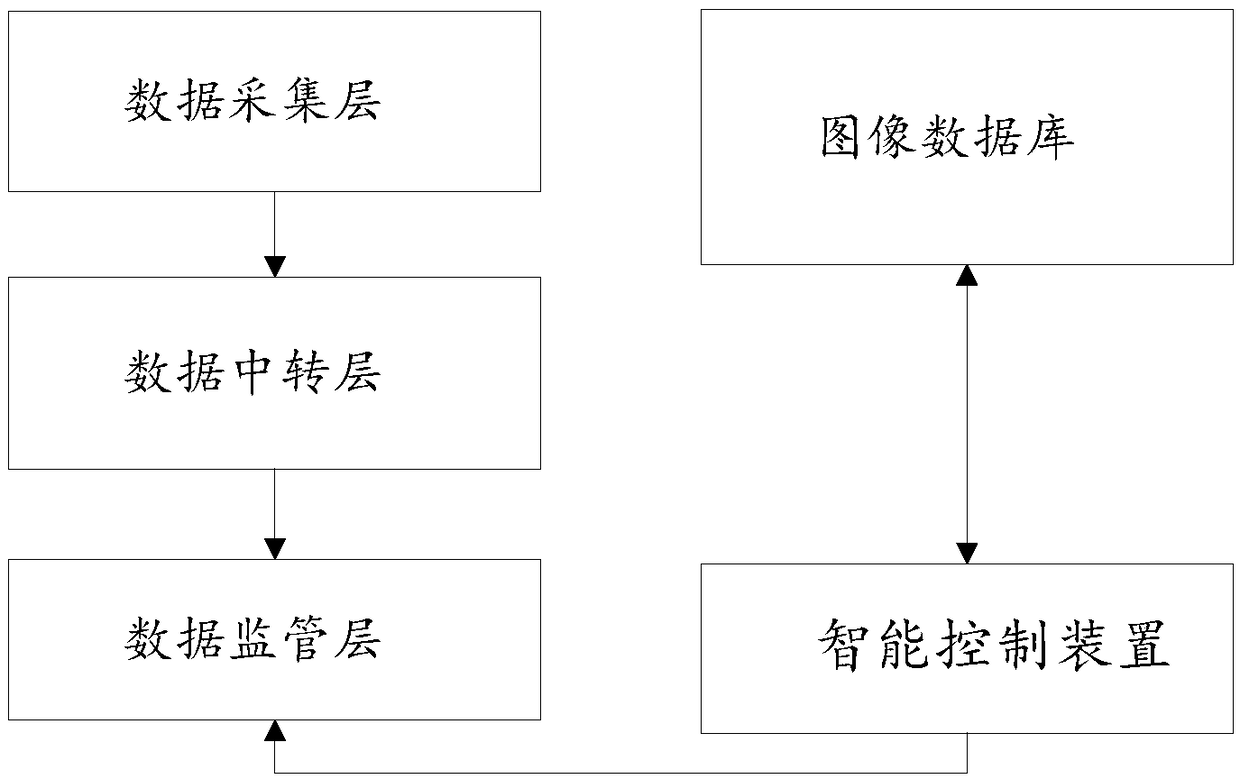

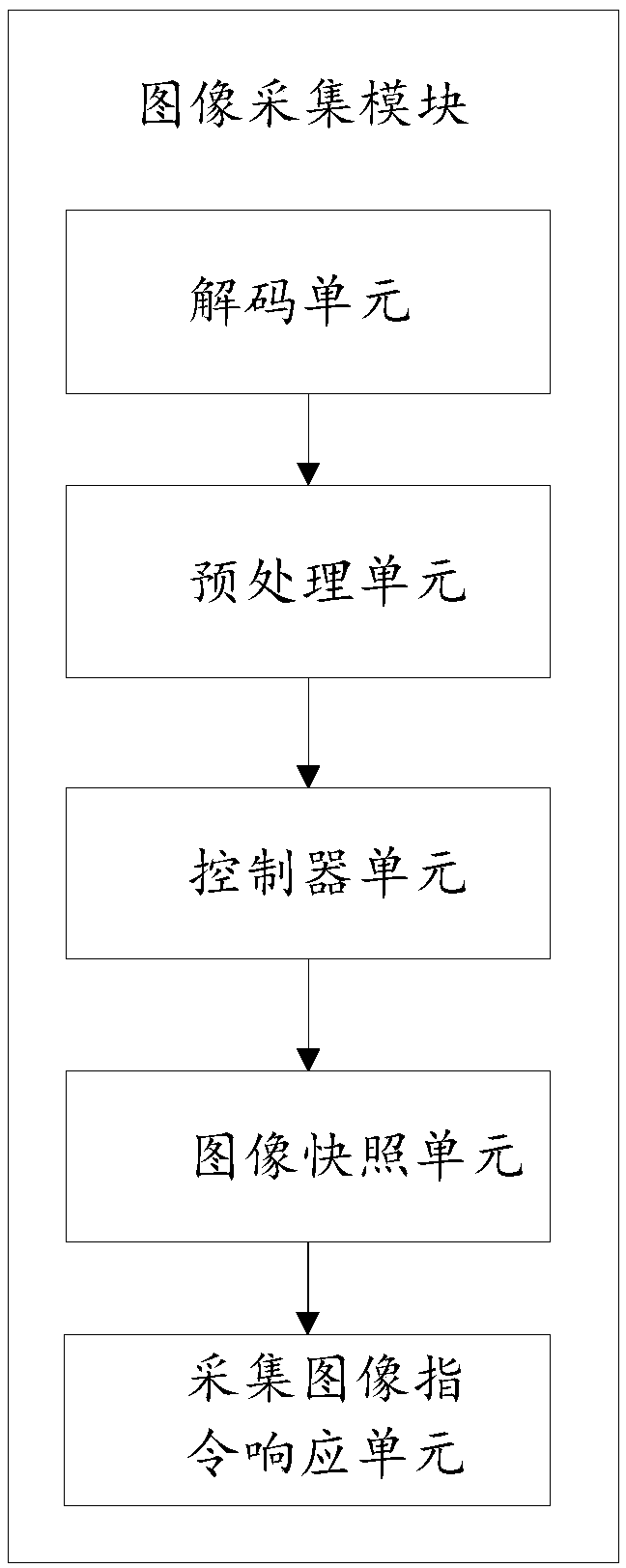

Elevator system with three-level monitoring network

The invention provides an elevator system with a three-level monitoring network. By the arrangement of the monitoring network with a three-level structure and an intelligent control device connected with the monitoring network in a communicated mode, an Internet of Things around an elevator is constructed, and therefore elevator operation environment is comprehensively monitored from multiple degrees, and the safety of the elevator is significantly improved. Besides, the elevator system is also capable of shooting a user video, responds to an image acquisition instruction sent by the user, acquires user images, matches the user images according to the acquired user images, and therefore a user identity is determined; according to the user identity, the destination floor which the user needs to go is obtained, and therefore a control instruction is automatically sent to a lift car to control the lift car to move to the destination floor, the user's operation is saved, and the function that users' destinations are determined automatically is achieved. The automated operation capacity of the elevator is significantly improved, the designated action of user conventional destinations is saved, and the user's experience is improved.

Owner:北菱电梯股份有限公司

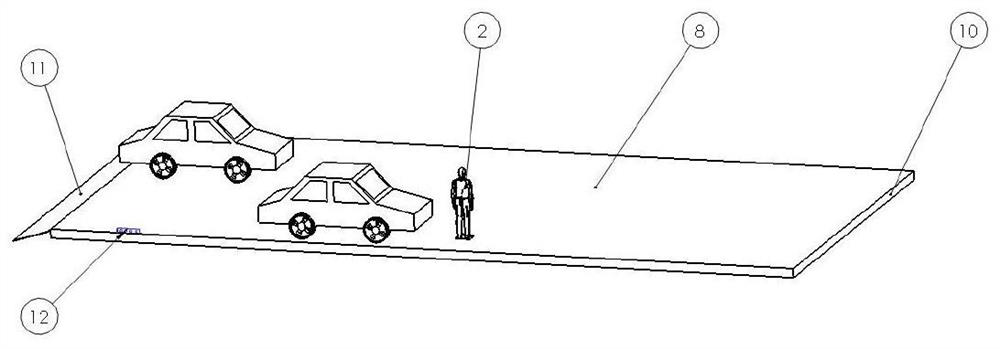

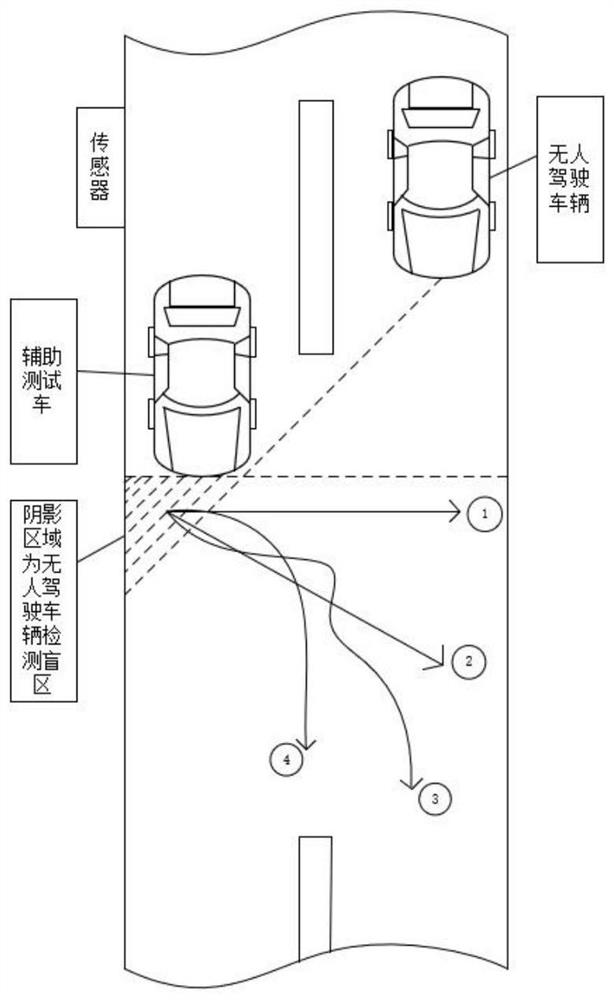

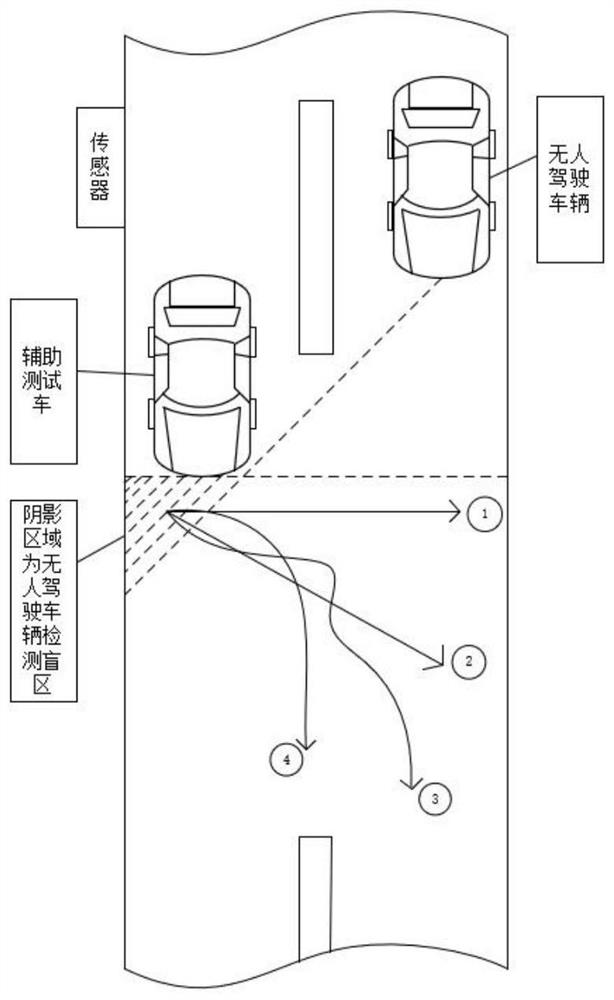

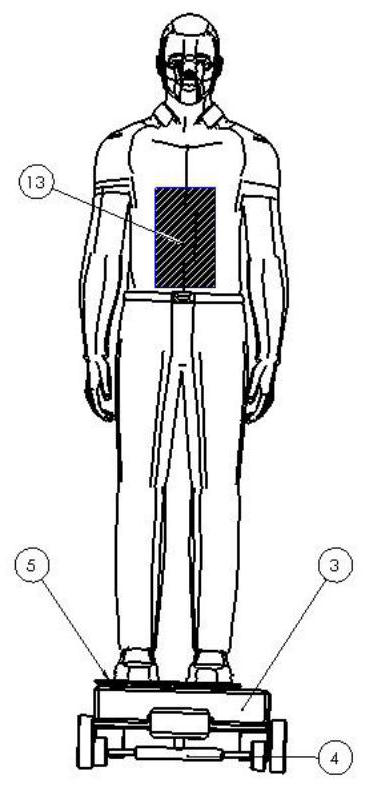

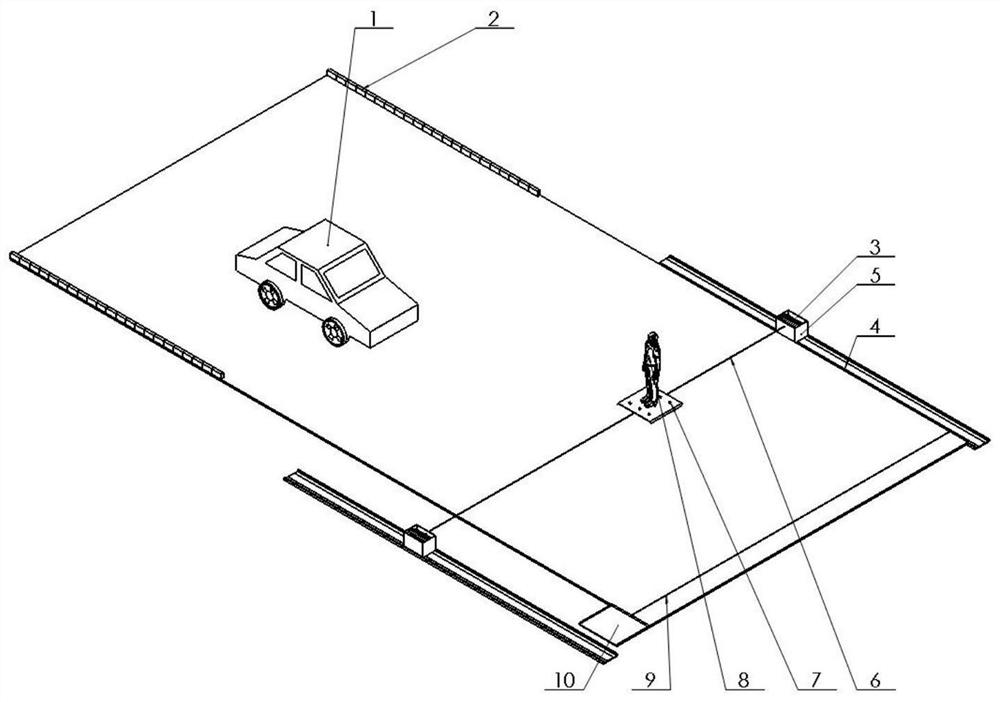

Method for testing driverless automobile by using moving target

ActiveCN112444403AImprove automation capabilitiesImprove drive test efficiencyVehicle testingElectric carsElectric vehicle

The invention discloses a method for testing a driverless automobile by using a moving target, belongs to the field of driverless automobile road test experiments, and aims to present road test sceneswith various different running tracks during the simulation of the running state of an obstacle in the running process of a driverless automobile. A device is arranged an open site; the moving targetcan be a simulated pedestrian or a motorcycle or an electric vehicle or a dog; the moving target is vertically placed beside a road initially; tin foil paper is pasted to the inner surface of the moving target and used for enabling a millimeter-wave radar to recognize the moving target in an unmanned driving test; a real vehicle is arranged on one side of the moving target, parks on the roadsideand is fixed in situ without moving; a blind area environment with a certain range is provided for the moving target, the blind area is similar to a triangular area; and as many test scenes as possible are provided for the driverless automobile.

Owner:DALIAN NATIONALITIES UNIVERSITY

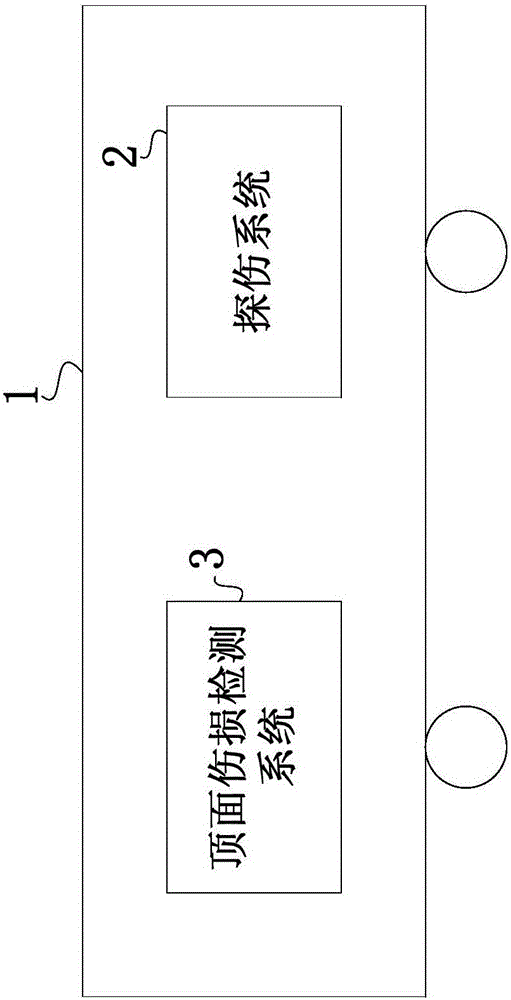

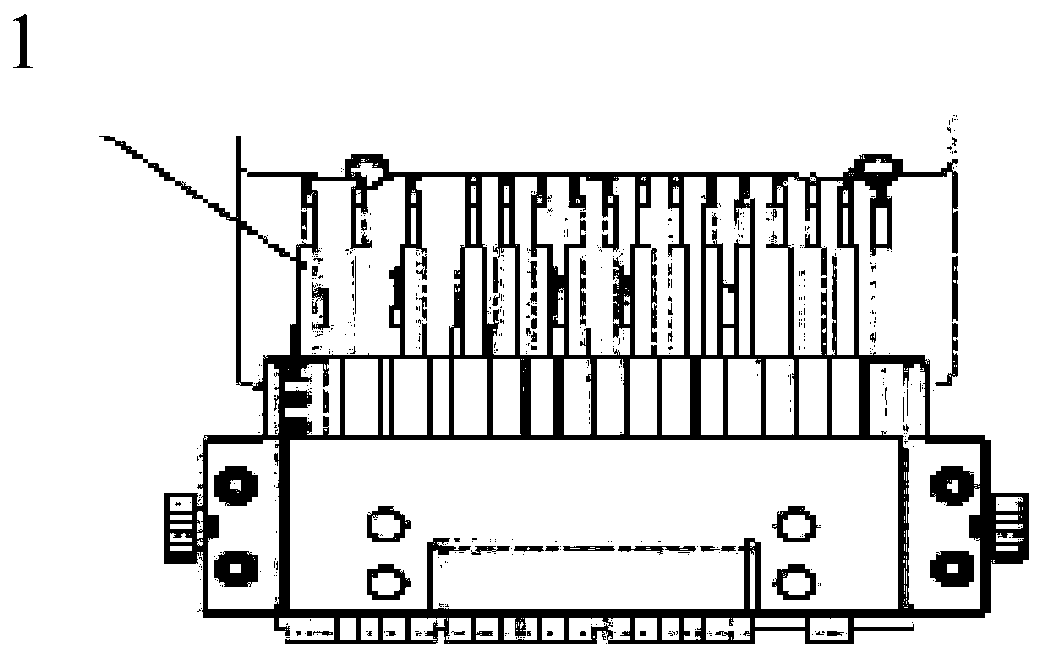

Rail flaw detection vehicle capable of detecting flaws on top surfaces of rails

ActiveCN105818823AImprove working environment comfortImprove automation capabilitiesRailway inspection trolleysRailway auxillary equipmentEngineering

The invention provides a rail flaw detection vehicle capable of detecting flaws on top surfaces of rails. The rail flaw detection vehicle comprises a flaw detection vehicle, a flaw detection system, and a top surface flaw detection system, wherein the flaw detection vehicle travels on the rails; the flaw detection system is mounted on the flaw detection vehicle and is used for detecting the flaws in the rails; the top surface flaw detection system is mounted on the flaw detection vehicle and is used for detecting the flaws on the surfaces and the subsurfaces of rail heads of the rails.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

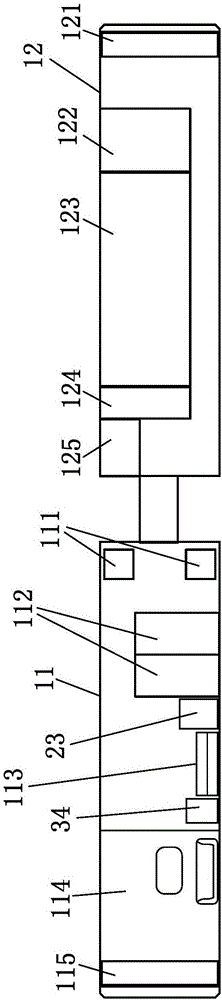

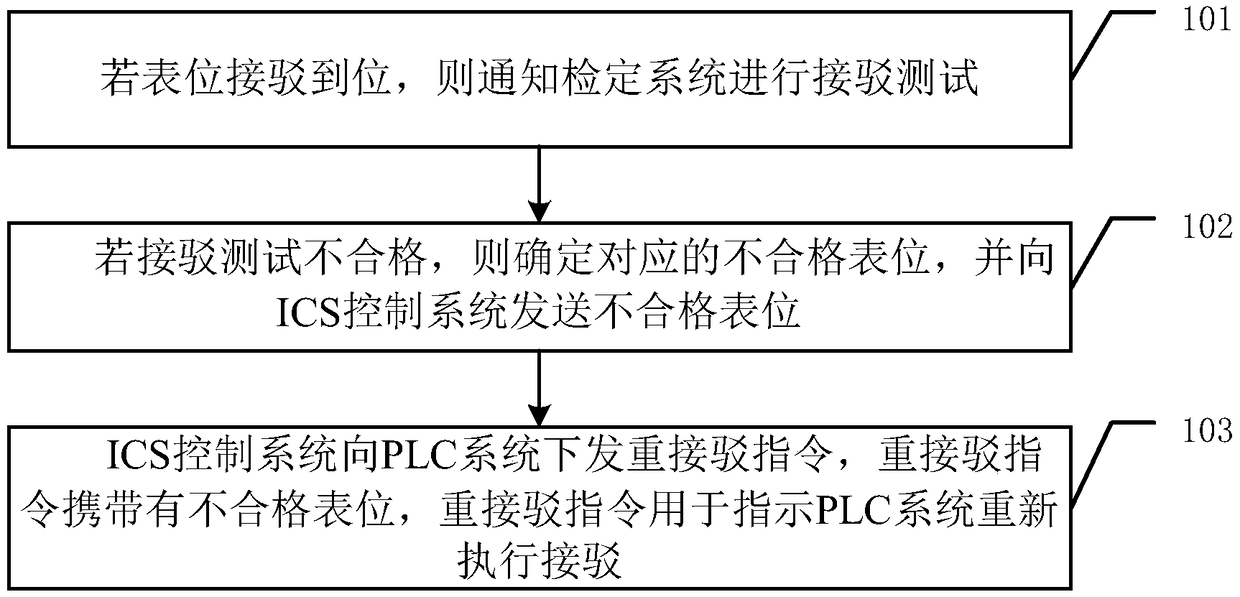

Calibration method and device for improving connection rate

InactiveCN109507631AImprove automation capabilitiesIncrease productivityElectrical measurementsControl systemComputer science

The embodiment of the invention discloses a calibration method for improving the connection rate. The calibration method comprises the steps that if epitope connection is carried out in place, a calibration system is informed to carry out a connection test; if the connection test is not qualified, a corresponding unqualified epitope is determined, and the unqualified epitope is sent to an ICS control system; the ICS control system issues a re-connection instruction to a PLC system, wherein the re-connection instruction carries the unqualified epitope and is used for indicating the PLC system to execute connection again. In this way, in the automatic metering and calibration process, if the connection test is not qualified, the ICS system is informed of the corresponding unqualified epitope, the re-connection instruction is issued to a PLC, the re-connection instruction is used for indicating the PLC system to execute connection again, automatic connection of the epitope is achieved, and the automatic work capacity and production efficiency of an epitope inspecting line are improved.

Owner:GUANGDONG POWER GRID CO LTD +1

Automatic edge cutting device for stamping die

PendingCN112845766AShorten the production cycleIncrease productivityShaping toolsMetal-working feeding devicesStampingEngineering

The invention relates to the technical field of stamping machining equipment, and discloses an automatic edge cutting device for a stamping die. The automatic edge cutting device comprises a supporting box body, the inner side of the middle of the supporting box body is fixedly connected with a rotary positioning mechanism in a sleeving manner, a lower stamping die is fixedly installed on the top face of the rotary positioning mechanism, and a workpiece is movably sleeved with the interior of the lower stamping die; and the two sides of the top face of the workpiece are movably connected with constant pressure mechanisms, the bottom faces of the constant pressure mechanisms are fixedly connected to the top face of the middle of the supporting box body, a lower pressing sleeve is arranged at the top of the workpiece, and the inner side of the top of the lower pressing sleeve is fixedly connected with an upper stamping die in a sleeving manner. According to the automatic edge cutting device for the stamping die and an edge cutting method of the automatic edge cutting device, through mutual cooperation of four mechanisms including the constant pressure mechanisms, an adjusting composite box body, an edge cutting mechanism and an advancing mechanism, redundant materials of the workpiece are subjected to automatic edge cutting operation after the workpiece is stamped, an integrated stamping and edge cutting machining technology is achieved, the production cycle of the workpiece is shortened, and the production efficiency is improved.

Owner:赣州佳广智能装备科技有限公司

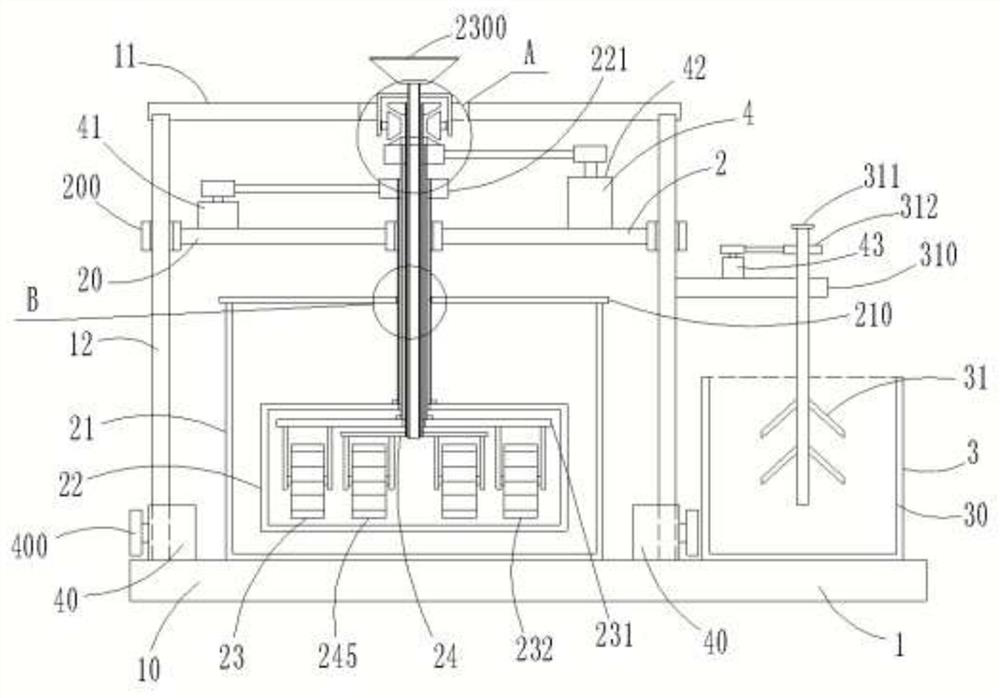

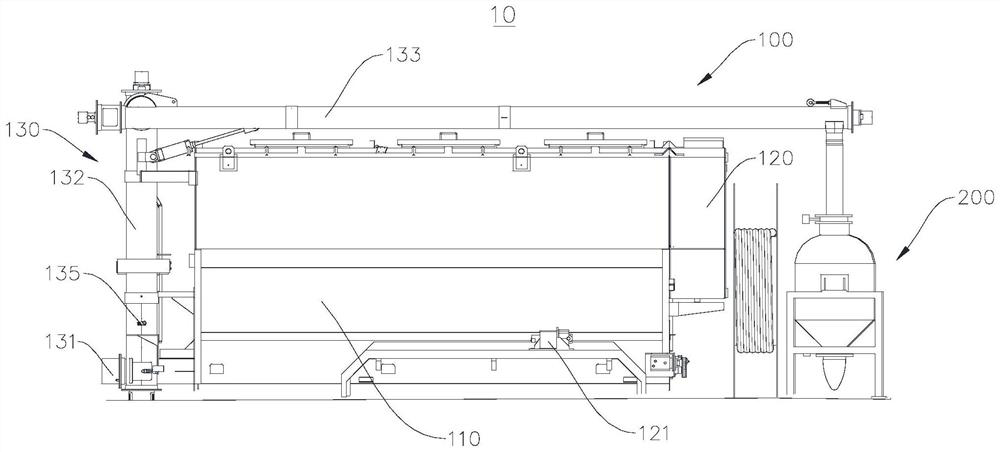

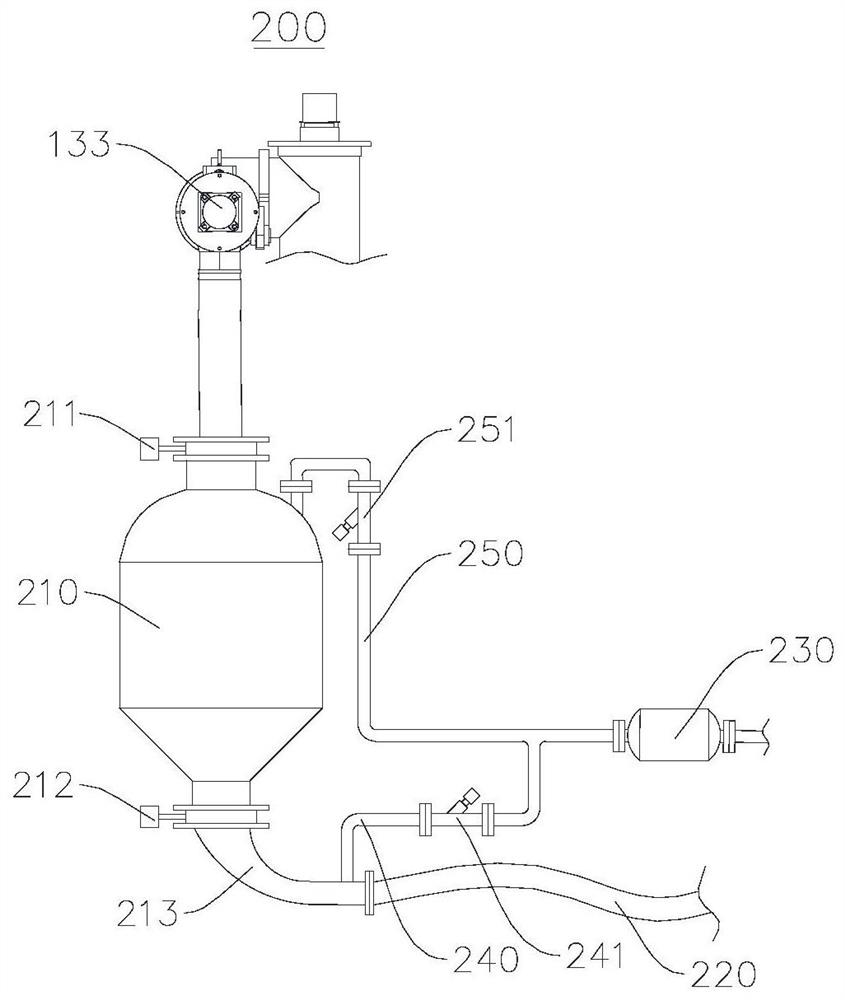

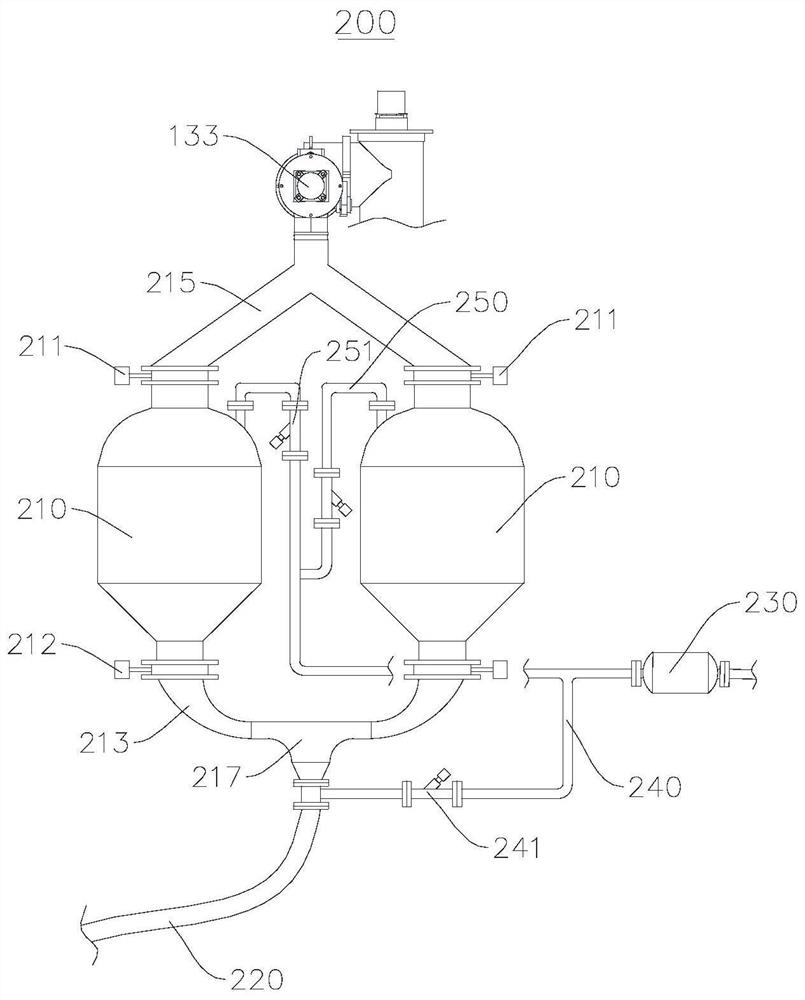

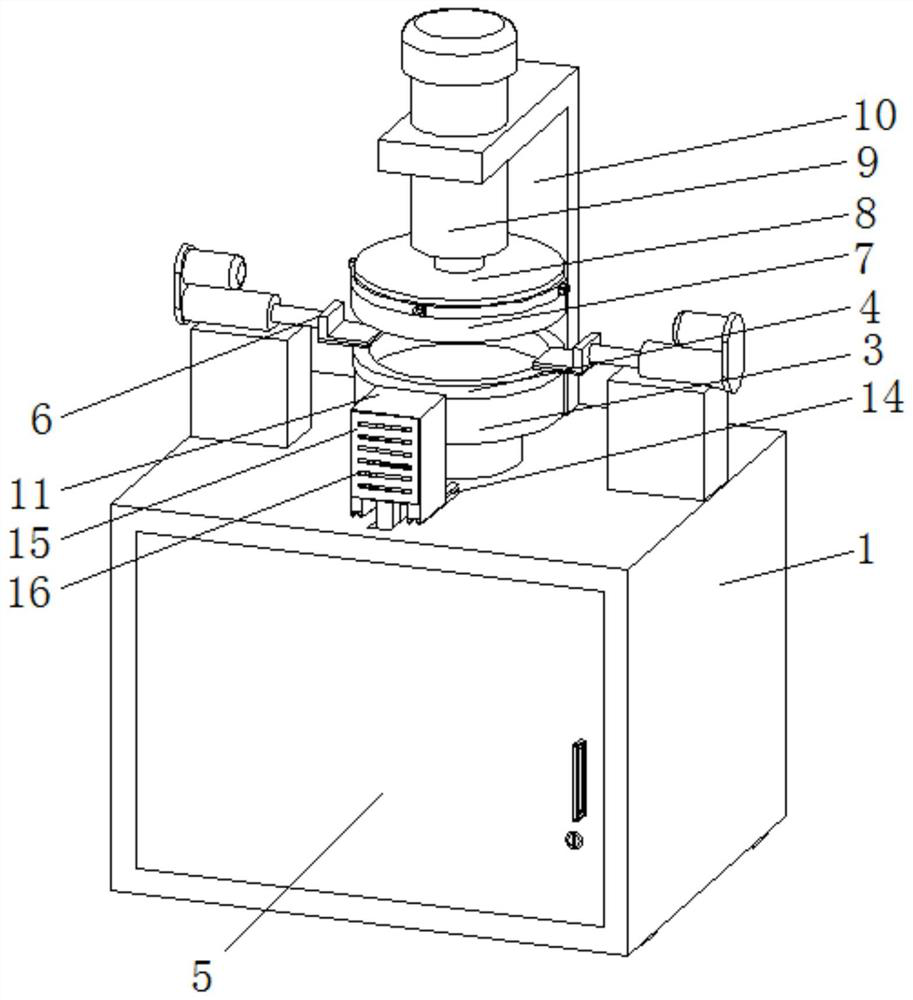

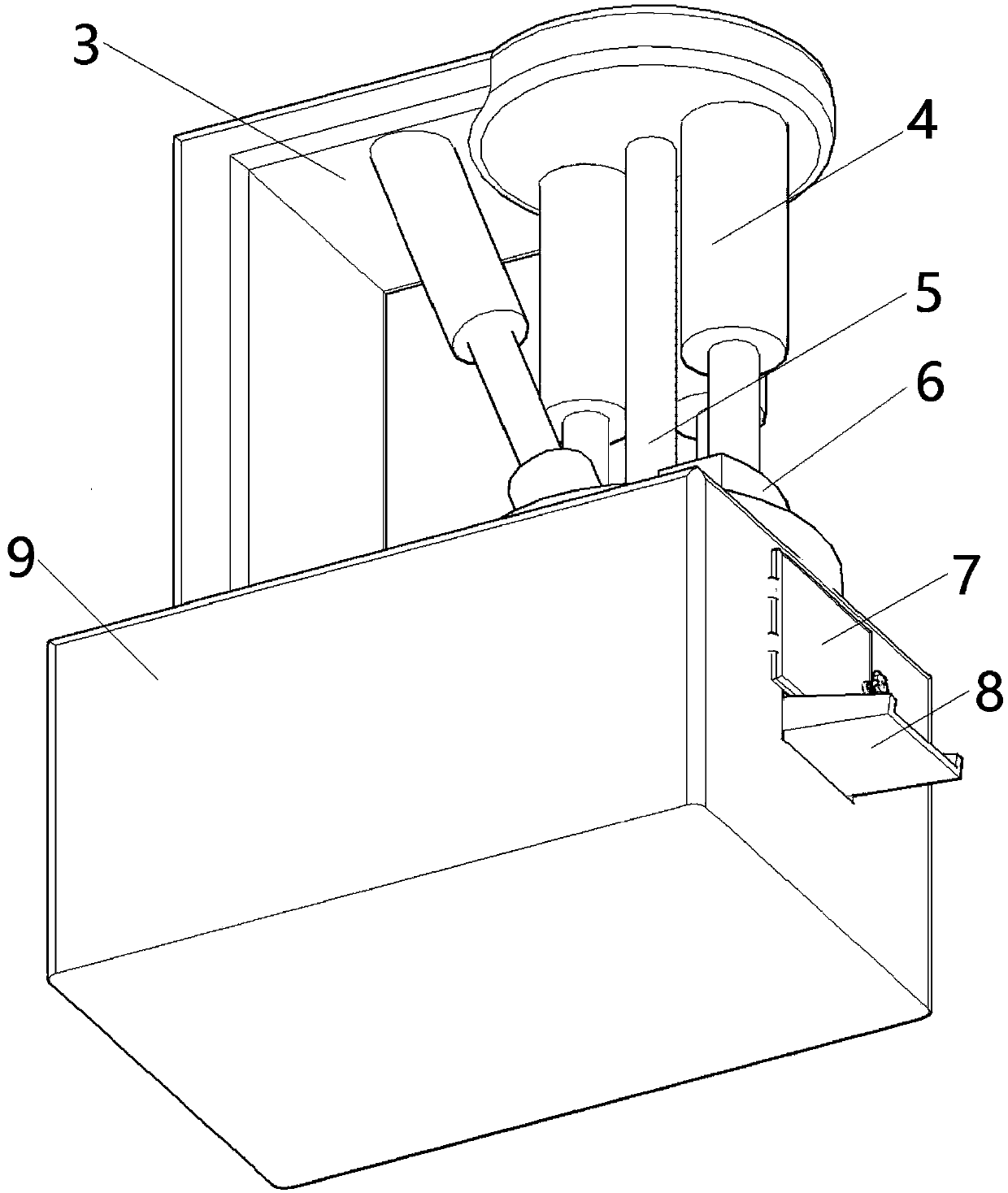

Extraction device and method for recycling phosphorus in sludge incineration ash

ActiveCN111646444AImprove automation capabilitiesIncrease productivityPhosphatesTransportation and packagingElectric machinePhosphorus

The invention discloses an extraction device and method for recycling phosphorus in sludge incineration ash. The device comprises a mounting frame, an acid leaching assembly, a precipitation assemblyand a power assembly, a sliding column is arranged on the mounting frame, the acid leaching assembly comprises a lifting plate, an acid leaching cylinder, an ash residue cylinder and a mixing component, the lifting plate is connected with the sliding column, the acid leaching cylinder is arranged on a bottom plate, the ash residue cylinder is arranged in the acid leaching cylinder, the mixing component is arranged in the ash residue cylinder, the precipitation assembly comprises a precipitation cylinder and a stirrer, the precipitation cylinder is connected with the acid leaching cylinder, thestirrer is arranged at the upper end of the precipitation cylinder, the power assembly comprises a lifting motor, a first mixing motor, a second mixing motor and a stirring motor, the lifting motor provides power for the lifting plate, the first mixing motor and the second mixing motor provide power for the ash residue cylinder and the mixing component respectively, and the stirring motor provides power for a second belt wheel. The device is reasonable in structural design, can effectively promote the phosphorus recovery efficiency, and is suitable for large-scale popularization.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

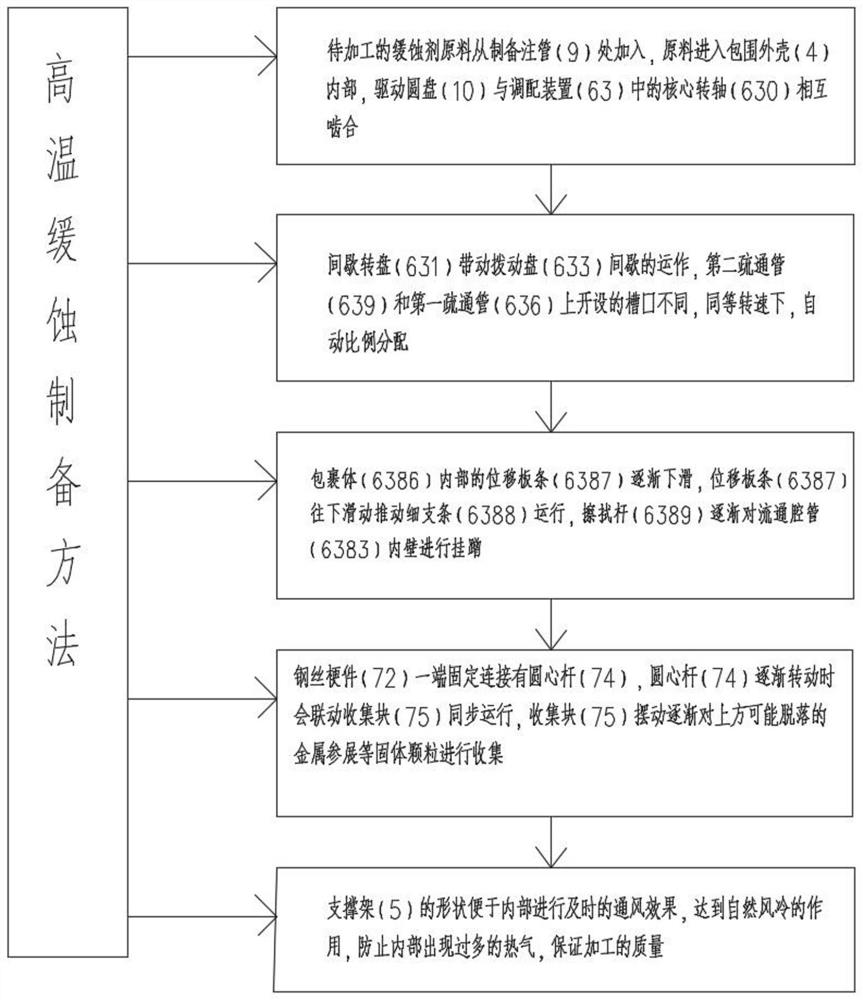

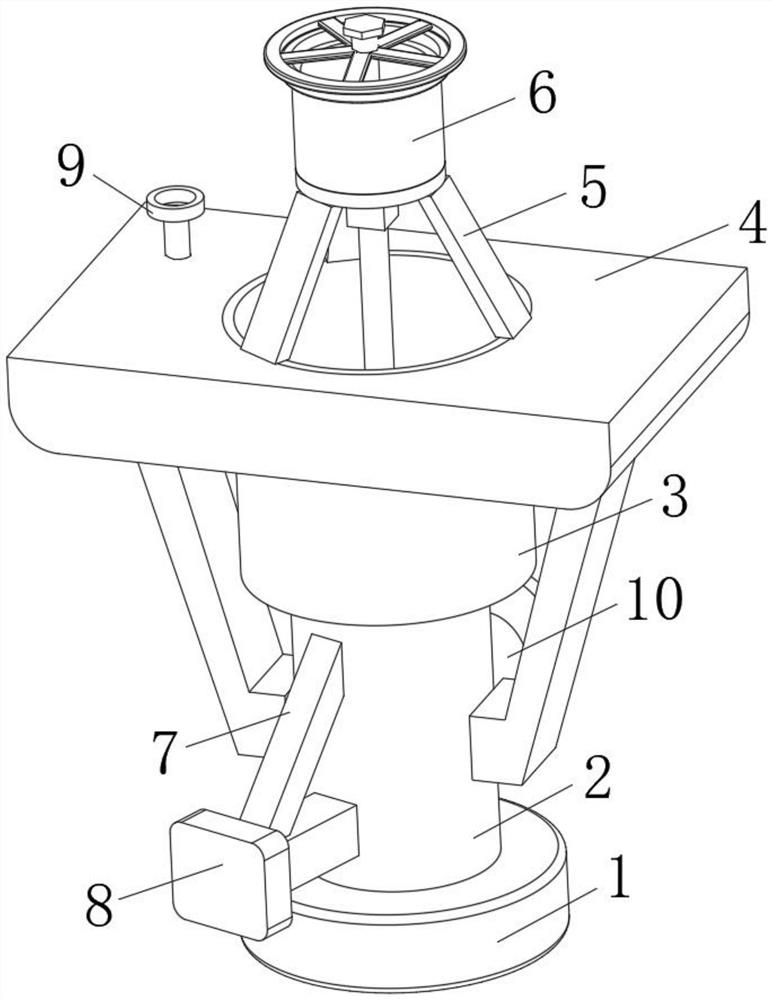

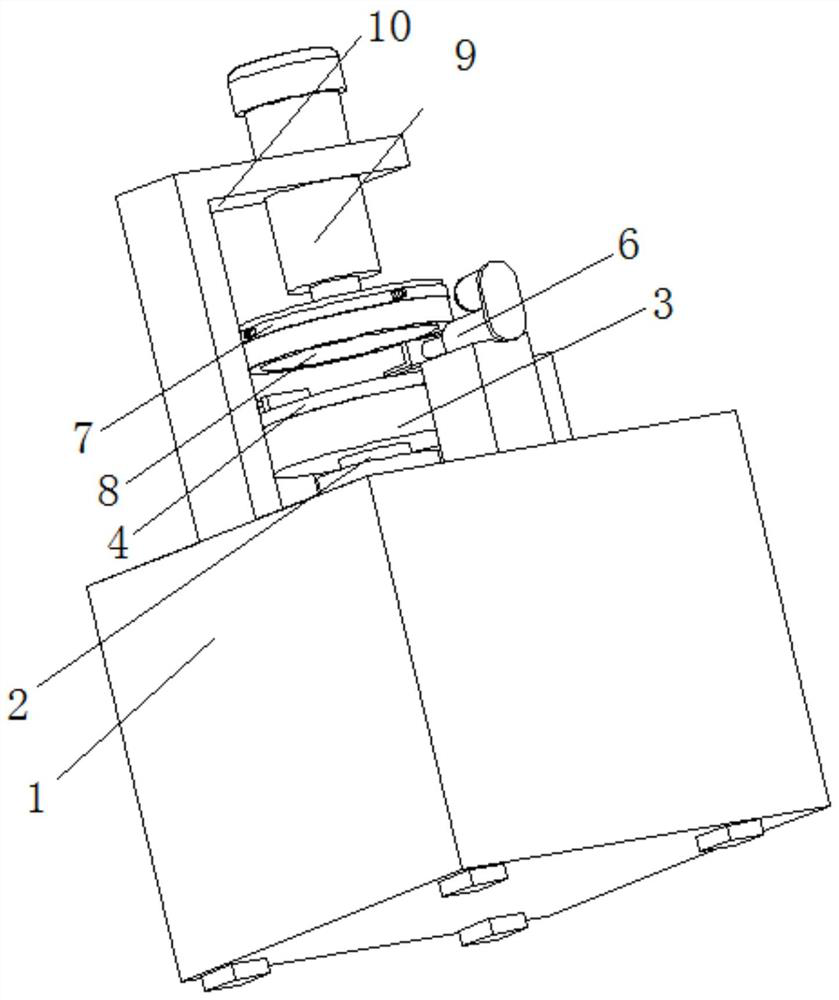

Preparation device and preparation method of high-temperature corrosion inhibitor

InactiveCN114682154AWith automatic operationHas a mixing effectTransportation and packagingMixer accessoriesSoil sciencePipe

The invention relates to the technical field of corrosion inhibitors, and discloses a high-temperature corrosion inhibitor preparation device and method.The high-temperature corrosion inhibitor preparation device comprises a metal base, a supporting table column is fixedly connected to the top of the metal base, a mixing pipeline is fixedly connected to the top of the supporting table column, and a mixing device is fixedly connected to the top end of a supporting frame; the left side of the upper surface of the surrounding shell is fixedly connected with a remark making pipe, and the remark making pipe penetrates through the surrounding shell and extends to an inner cavity of the surrounding shell. According to the high-temperature corrosion inhibitor preparation device and method, the first dredging pipe and the second dredging pipe rotate mutually, raw material solutions in the first dredging pipe and the second dredging pipe are spilled out from notches of the first dredging pipe and the second dredging pipe, and the notch of the second dredging pipe is larger than that of the first dredging pipe, so that the proportions of raw materials injected into the first dredging pipe are different; finally, the effect of automatically blending the raw materials is achieved through the automatic adjustment effect, and compared with manual blending in the prior art, the working efficiency is improved.

Owner:山东晨煜石油技术有限公司

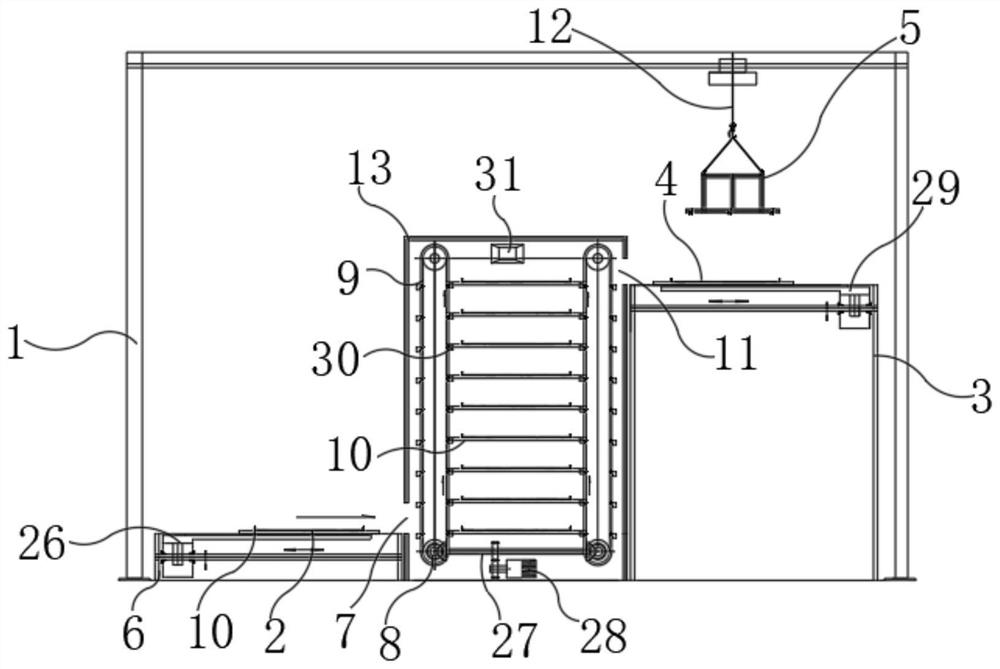

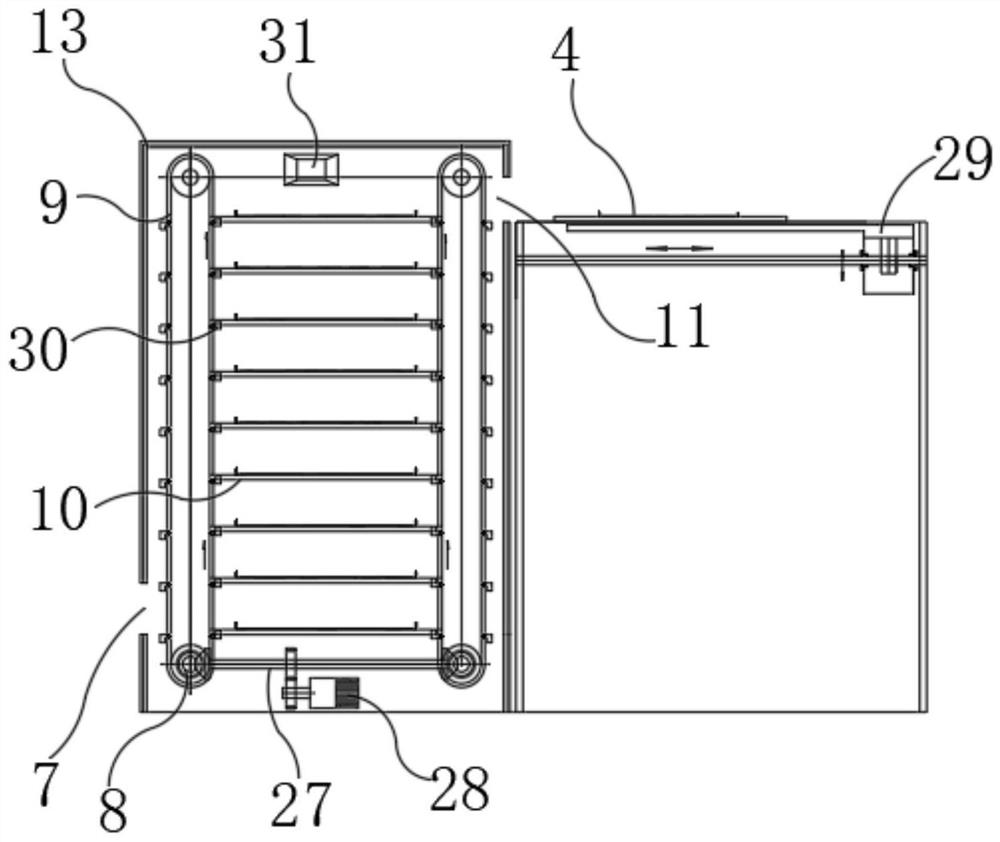

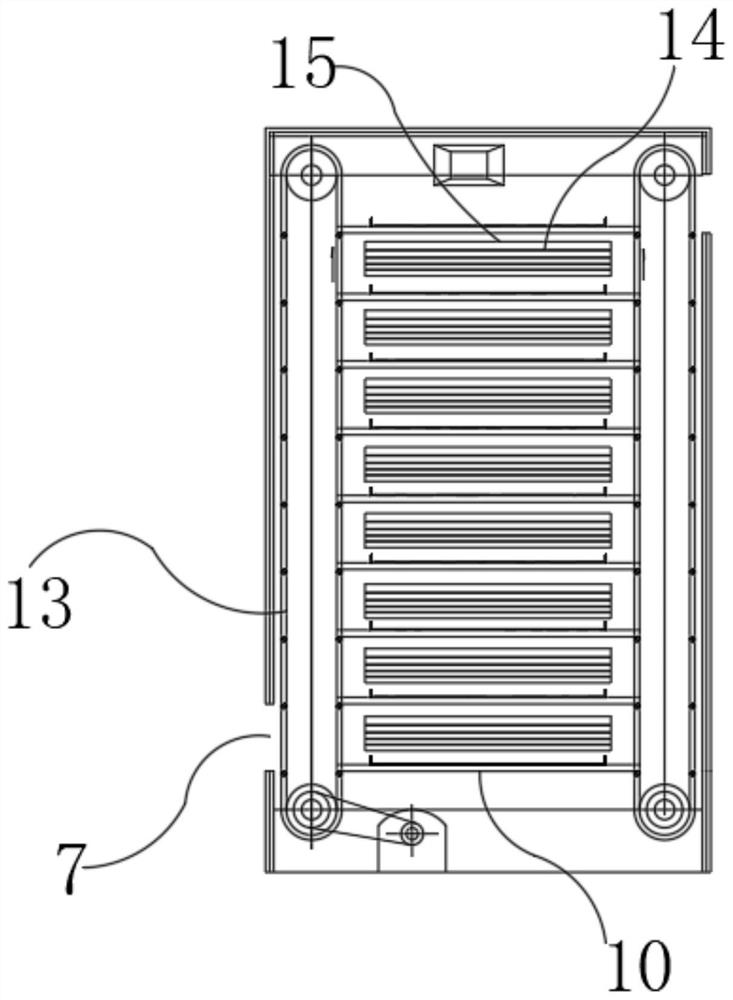

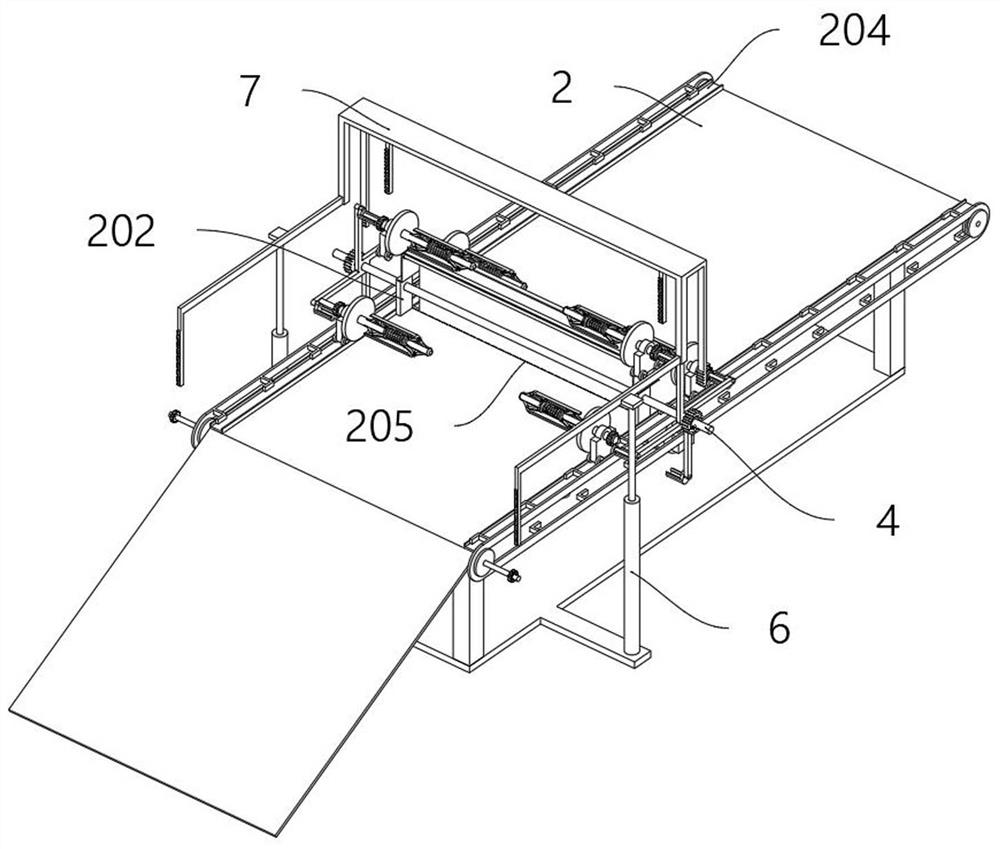

Automatic vertical drying and curing box for metal composite curtain wall plate

InactiveCN113926670AConvenient processing and drying operationGood processing and dryingPretreated surfacesCoatingsProduction lineTextile printer

The invention discloses an automatic vertical drying and curing box for a metal composite curtain wall plate. The automatic vertical drying and curing box for the metal composite curtain wall plate comprises a device main body, wherein a charging workbench, a vertical hot-air drying oven and a high discharging table are sequentially installed at the bottom of the device main body, wherein a charging port is formed in the lower end of one side of the vertical hot-air drying oven, and a discharging port is formed in the upper end of the other side of the vertical hot-air drying oven; and closed chain wheels are installed at the two sides in the vertical hot-air drying oven, locating pins are arranged on the closed chain wheels, a speed reducer is installed at the bottom of the vertical hot-air drying oven, and a transmission shaft is arranged at the output end of the speed reducer. The automatic vertical drying and curing box for the metal composite curtain wall plate is specially developed for an intelligent automatic manufacturing production line machine for the color-coated and printed metal composite curtain wall plate, has the characteristics of stable and reliable operation, controllable temperature, adjustable speed, high efficiency and unmanned operation, is intelligent manufacturing equipment, and fills the blank of an automatic drying process for gluing in a domestic manufacturing process for the metal curtain wall plate.

Owner:SHANGHAI PILOT NEW MATERIAL RES CO LTD

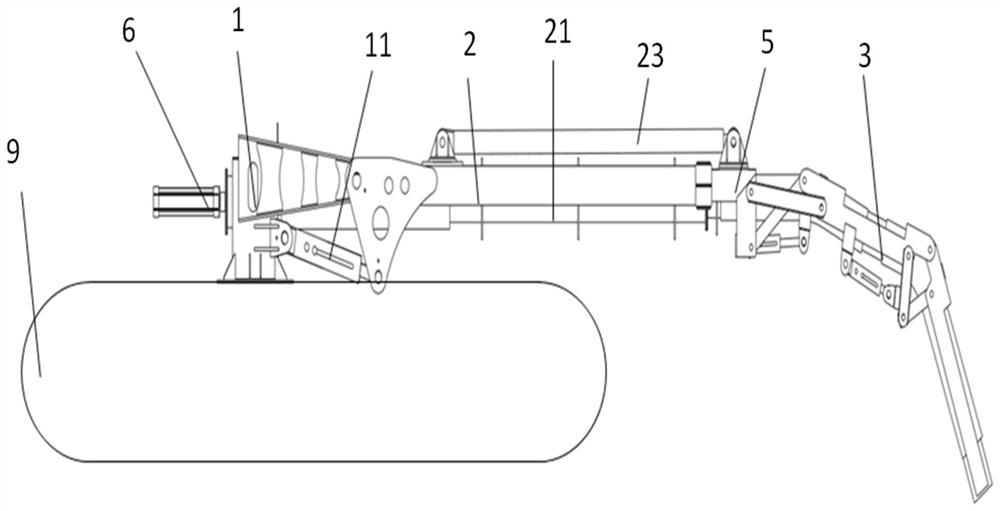

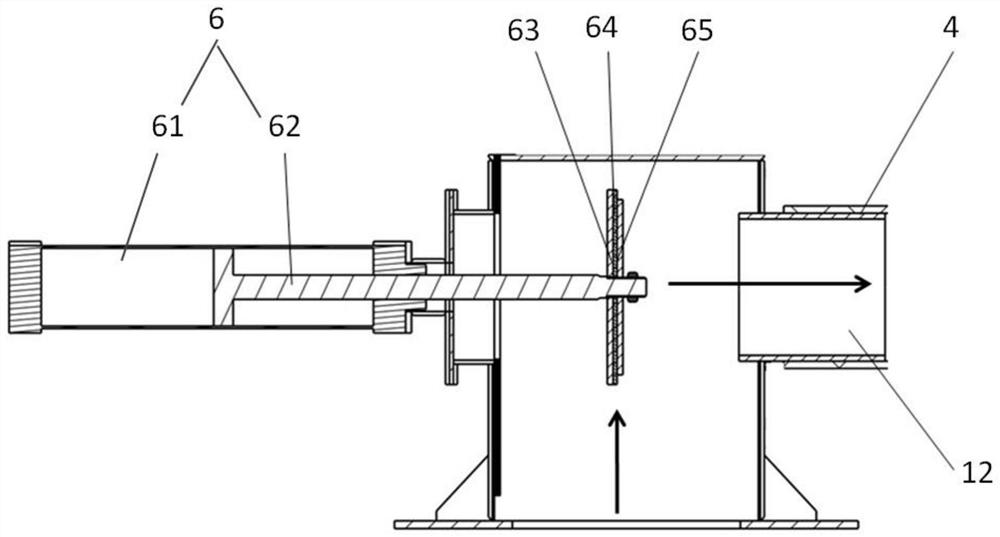

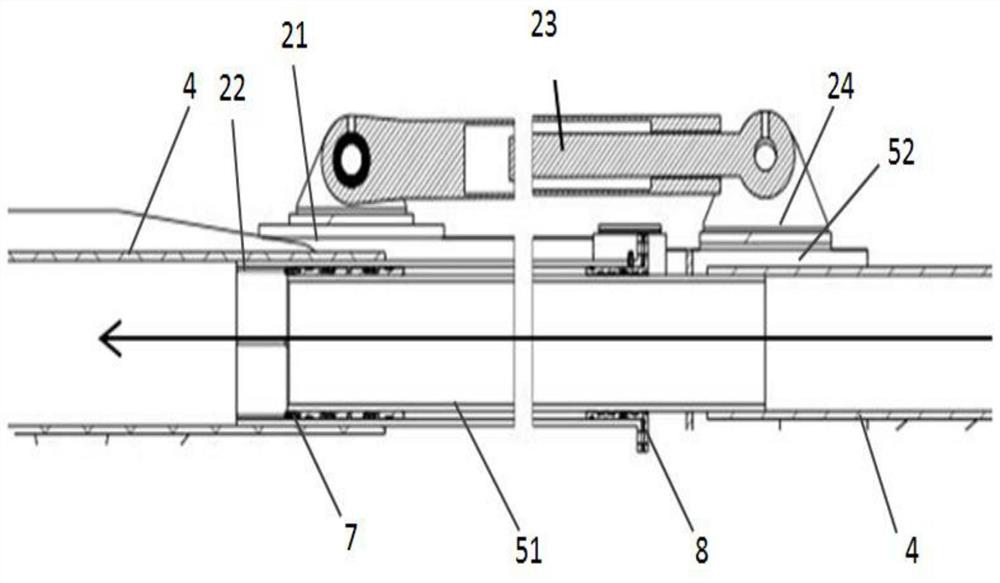

Multi-degree-of-freedom suction arm support and dredging vehicle

PendingCN113846745ASuction achievedAvoid secondary pollutionSewer cleaningMarine engineeringGas passing

The invention discloses a multi-degree-of-freedom suction arm support and a dredging vehicle. The multi-degree-of-freedom suction arm support comprises a swing mechanism, a lifting mechanism, a slip mechanism, a luffing mechanism and a suction hose, the lifting mechanism comprises lifting arm support and a suction outer pipe, slip mechanism comprises a slip rod and a suction inner pipe, the slip mechanism is in transmission connection with the luffing mechanism through the slip rod, the outer suction pipe sleeves the inner suction pipe, a discharge port of the swing mechanism communicates with an anti-overflow sealing mechanism, and the swing mechanism, the lifting mechanism, the slip mechanism and the luffing mechanism are in pipeline connection through the suction hose. When the dredging vehicle performs suction operation, multi-degree-of-freedom, multi-angle and multi-direction suction can be achieved, meanwhile, a suction pipeline is accurately and effectively controlled so as to perform suction, transfer and other work, and in the transportation process, the anti-overflow sealing mechanism can be used for sealing the feeding port of a tank body, so that secondary pollution caused by sewage and peculiar smell gas overflowing through the suction hose is prevented.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

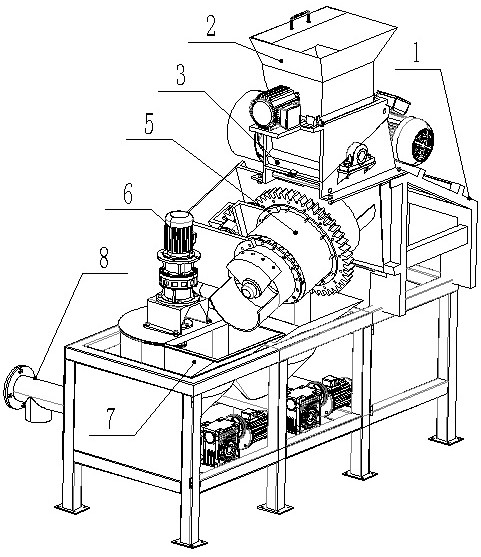

A kind of sweet potato starch extraction device

ActiveCN112221668BGuaranteed crushing speedContinuously workingGrain treatmentsFood scienceChipped potatoesPotato starch

A sweet potato starch extraction device, comprising: a frame body, a crushing device, a crushing device, an anti-blocking mechanism, a screening device, a crushing device, a receiving hopper and a molding device; by installing multiple rows of teeth in the crushing device, the sweet potato The crushing speed makes the work more continuous and improves the work efficiency; the crushed sweet potato pieces enter the crushing device, and then enter the screening device after crushing; through the filtration of the screening device, the sweet potato paddle directly passes through the collecting device. The hopper is recycled to the forming device, and the small sweet potato chips will enter the crushing device for further processing and then output to the forming device for starch extraction, avoiding external environmental interference, and high product quality; the present invention processes sweet potatoes through multiple processes Thorough crushing is carried out to achieve the maximum amount of starch extraction, and the automation effect is more sufficient, which solves the problems of low automation degree of manual operation and low starch quality.

Owner:张家界朝阳冲农产品开发有限责任公司

Solar Wind Wheel Mechanism

InactiveCN104879277BSimple structureEasy to get materialsFrom solar energyFinal product manufactureMechanical energyEngineering

Owner:郑迓仔

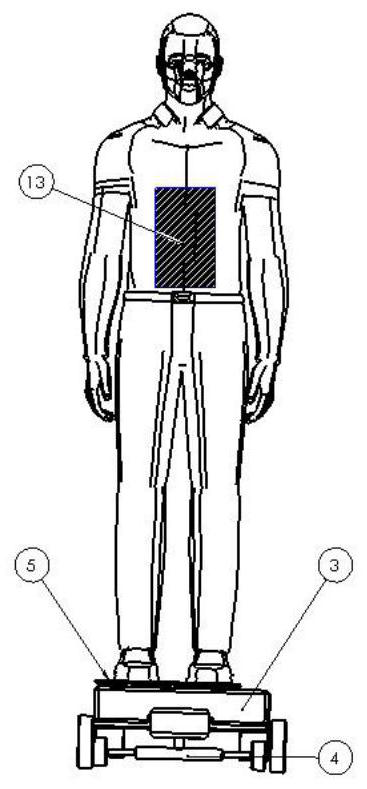

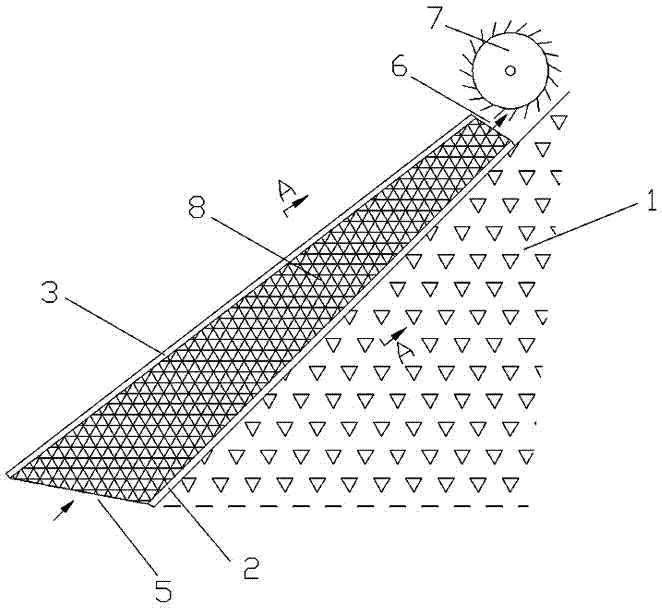

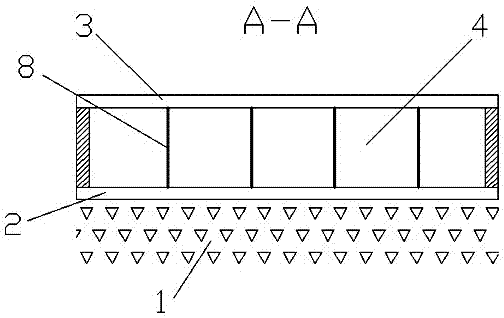

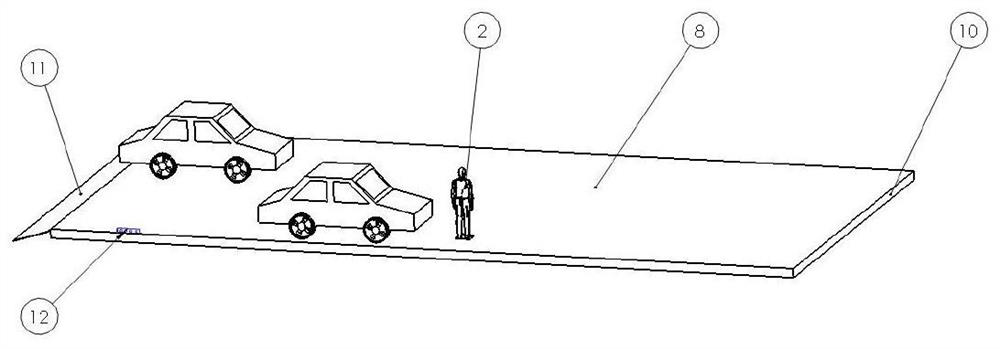

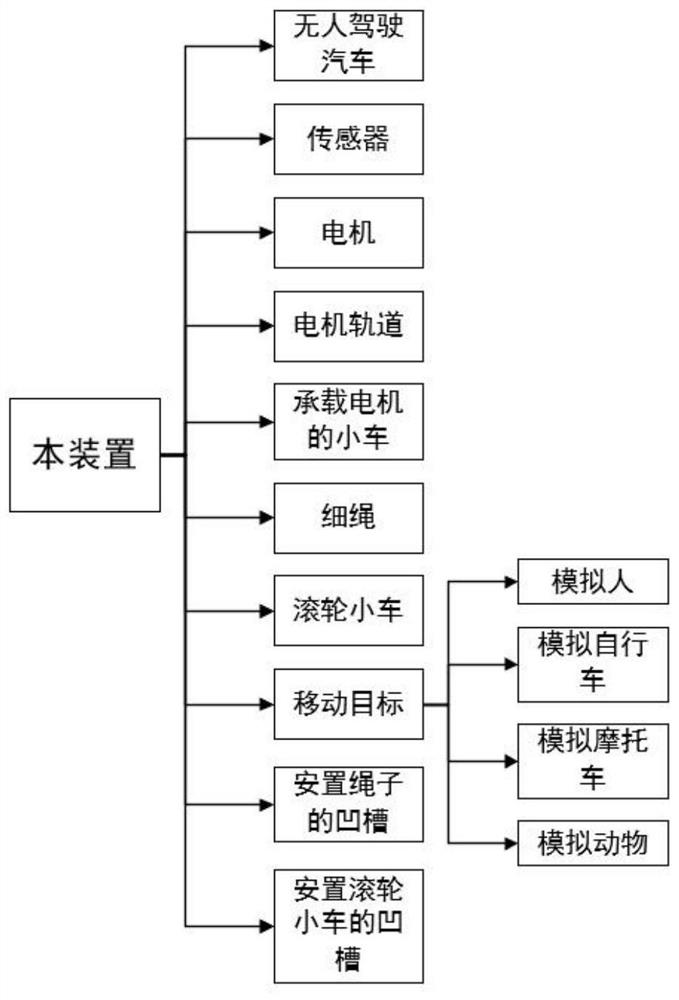

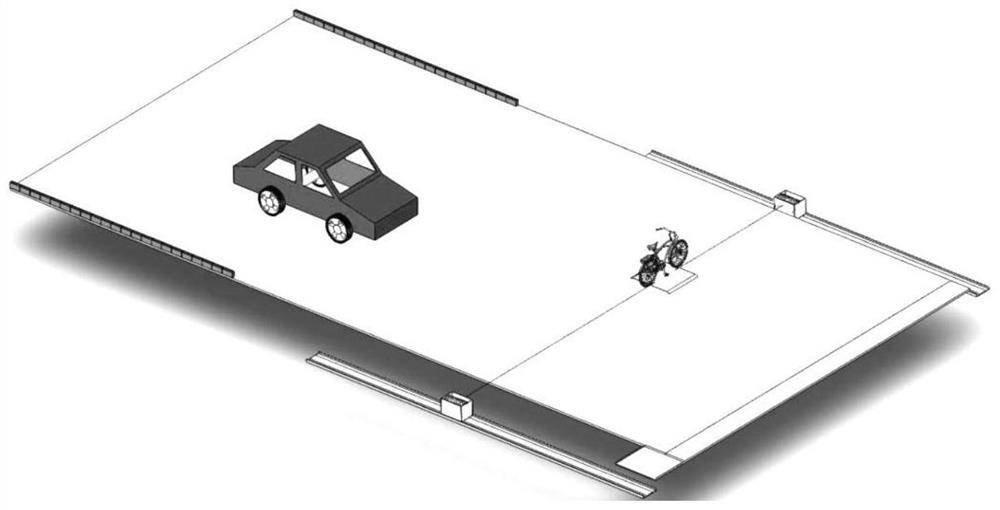

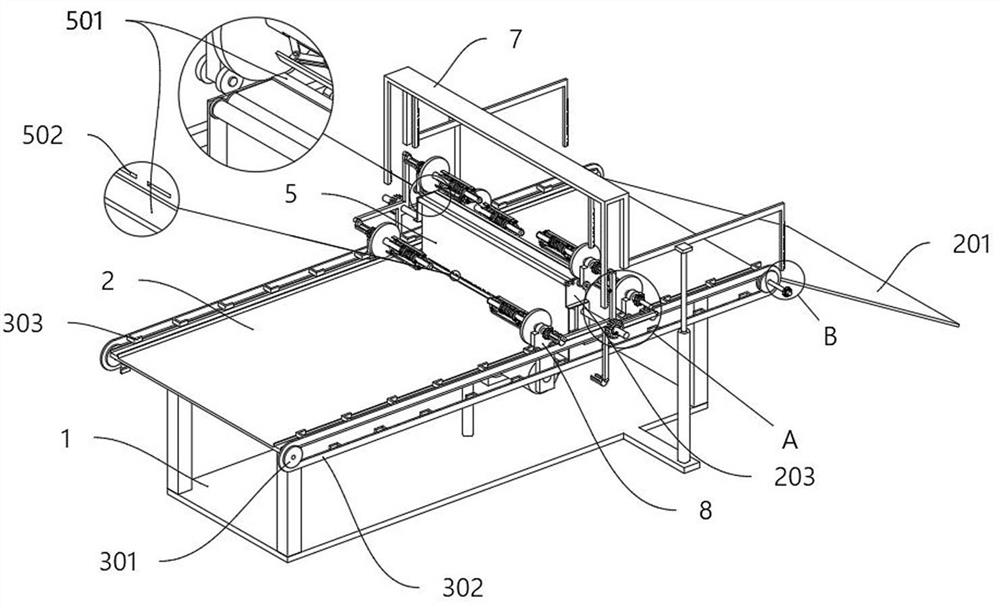

Driverless automobile testing device capable of controlling road surface moving targets

ActiveCN112444401AImprove automation capabilitiesImprove drive test efficiencyVehicle testingRoad surfaceSlide plate

The invention discloses a driverless automobile testing device capable of controlling road surface moving targets, belongs to the field of driverless automobile road test experiments, and aims to present road test scenes with various different running tracks during the simulation of the running state of an obstacle in the running process of a driverless automobile. A pulley trolley is a self-driving trolley, and an electromagnet is mounted on the pulley trolley; the pulley trolley is located between the road surface and the lower surface of a glass road plate and runs on the road surface; a sliding plate is provided with embedded balls, is arranged on an asphalt road surface on the upper surface of the glass road plate and is located above the electromagnet of the pulley trolley correspondingly; and therefore, when the electromagnet of the pulley trolley located below the glass road plate is powered on, the metal sliding plate located above the glass road plate can be attracted, so that the metal sliding plate moves along with the movable pulley trolley through the electromagnet, and as many test scenes as possible can be provided for the driverless automobile.

Owner:DALIAN NATIONALITIES UNIVERSITY

Background program monitoring method and monitoring device

ActiveCN108427616BImprove automation capabilitiesThe judgment result is accurateHardware monitoringMonitoring statusSoftware engineering

The invention provides a background program monitoring method. The method comprises the steps of traversing background service programs, and reading configuration files of all the background service programs; according to the configuration files of the background service programs, generating a monitoring state table of the background service programs; according to the monitoring state table, sending a first heartbeat signal to all the background service programs by a set time interval; and according to feedbacks of the background service programs to the first heartbeat signal, determining to perform restarting operation on the corresponding background service programs. The invention furthermore provides a background program monitoring apparatus. According to the background program monitoring method and the background program monitoring method apparatus, whether the background service programs run normally or not by sending the heartbeat signal to the background service programs, so that a judgment result is more accurate, the automatic running capability of a background program monitoring process can be improved, and the operation of manually performing state confirmation of the background service programs is avoided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

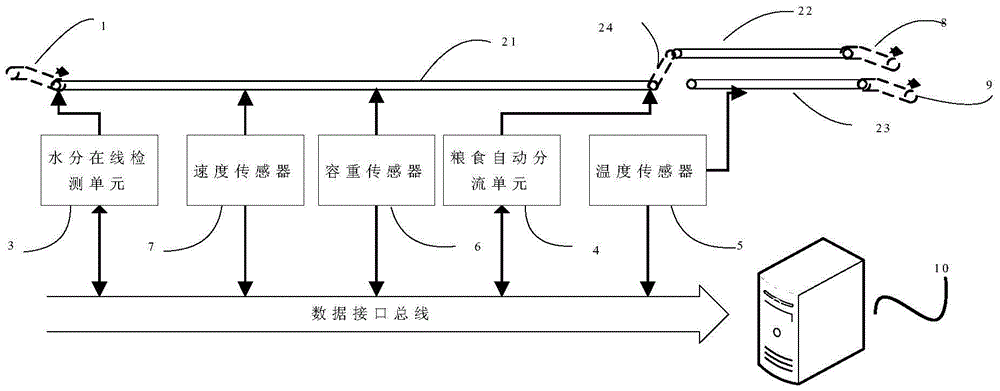

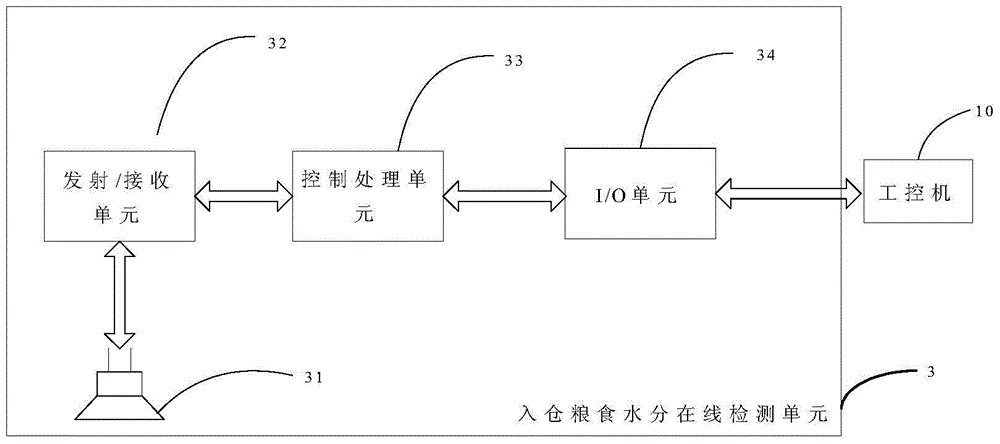

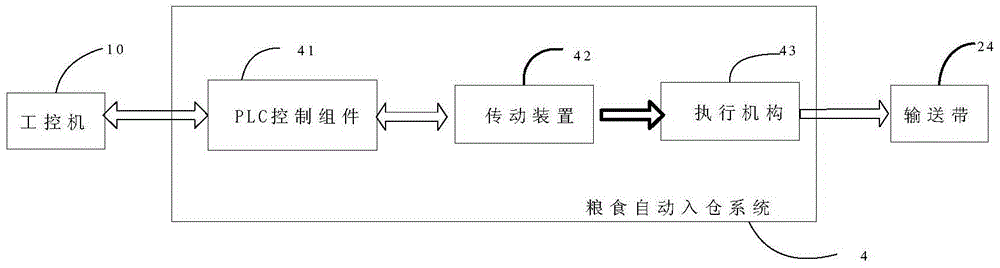

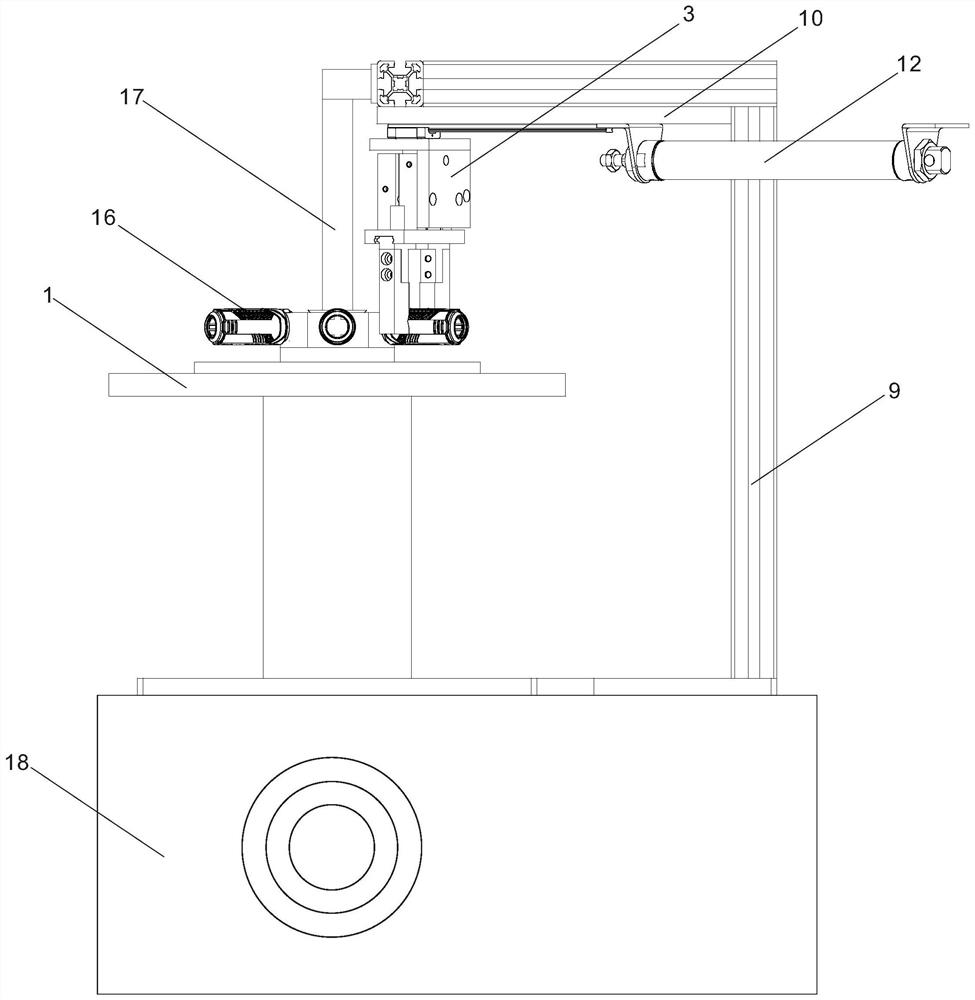

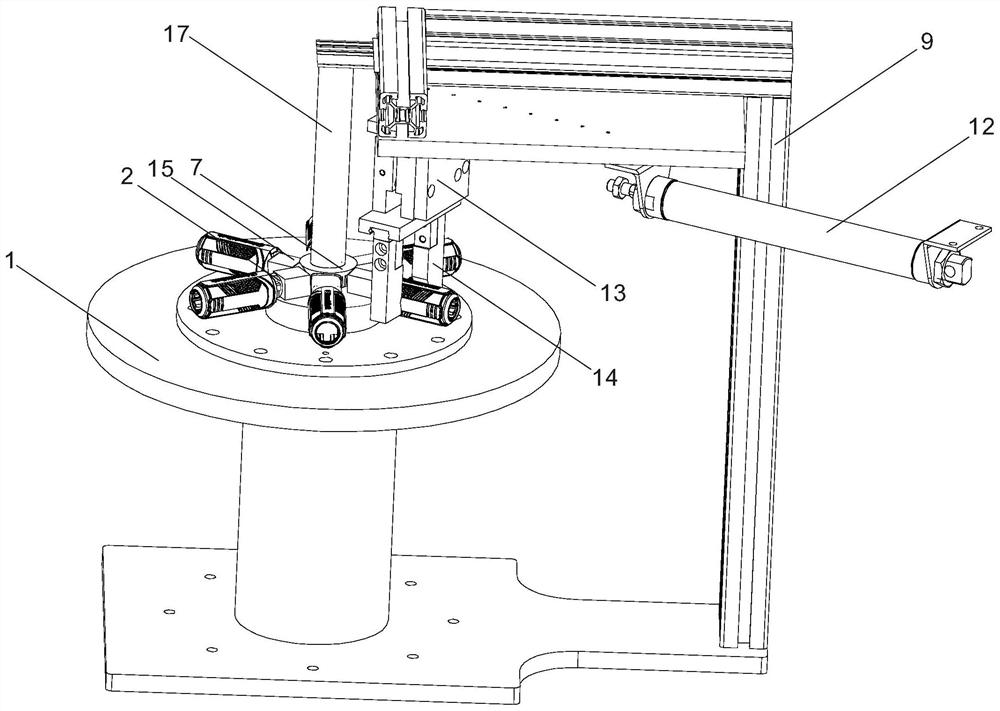

System and method for automatic storage of grain

ActiveCN104555477BPrevent mildewAvoid wastingConveyorsMoisture content investigation using microwavesMicrowaveProgrammable logic controller

Owner:AEROSPACE INFORMATION

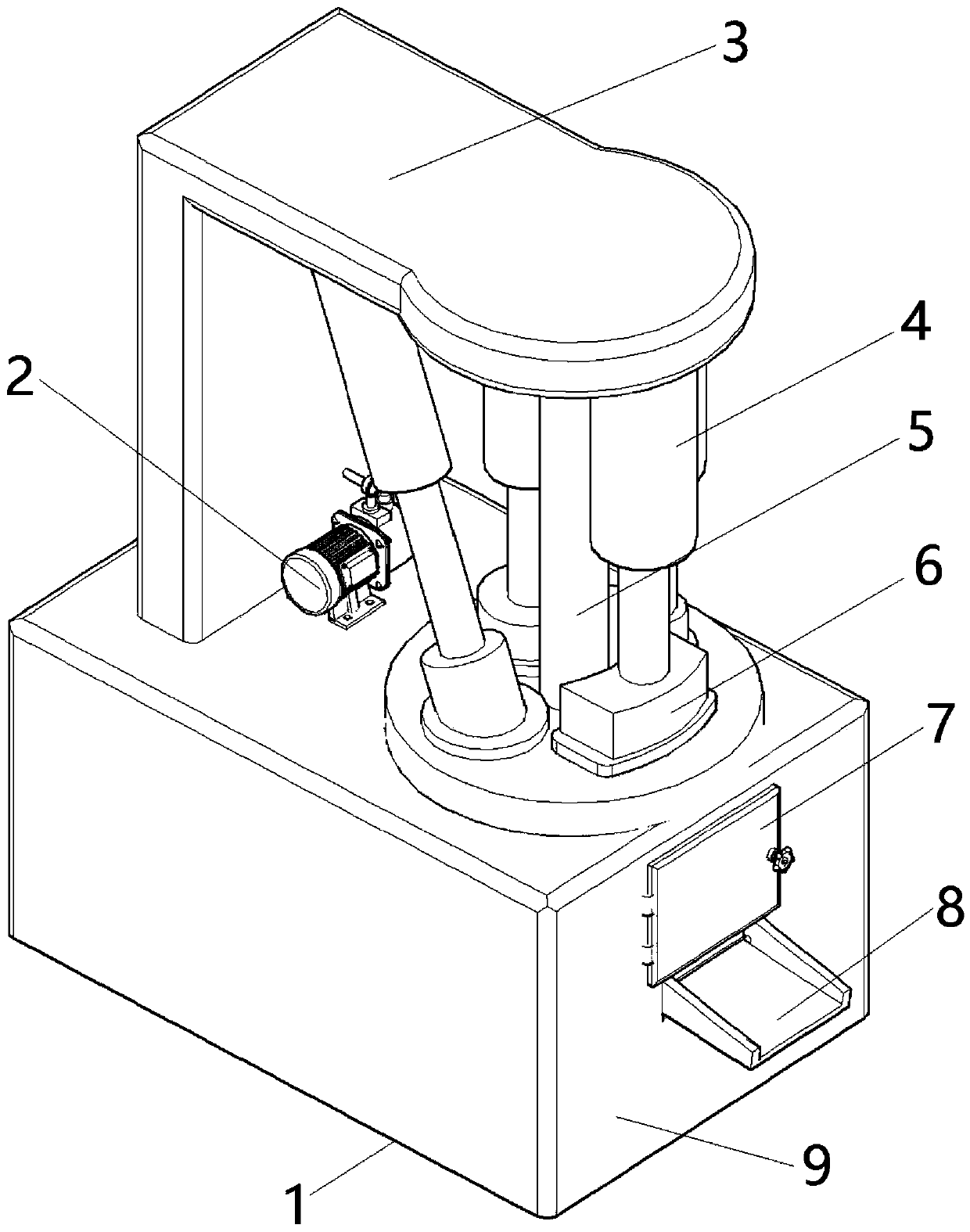

A plastic handle positioning and feeding device and a bronzing machine using the device

ActiveCN110816040BImprove automation capabilitiesImprove work efficiencyRotary pressesRotary conveyorsHot stampingPower efficient

The invention discloses a plastic handle positioning and feeding device, which comprises an intermittently moving dividing turntable, a workpiece support body and a discharge chuck. On the reciprocating mechanism, the unloading chuck corresponds to the discharge position of the dividing turntable, and the unloading chuck is electrically connected to a controller. The invention also provides a bronzing machine using the device. When the present invention works, the plastic handle workpiece is loaded on the workpiece support body, and is positioned on the workpiece support body. As the dividing turntable rotates, the workpiece is transported to different positions and pauses intermittently. During the intermittent pause, it accepts bronzing, printing or other The processing of the surface processing device is finally automatically unloaded from the dividing turntable through the unloading chuck. The plastic handle positioning and feeding device can improve the efficiency of automatic operation, improve work efficiency, liberate labor to a certain extent, and reduce labor intensity of personnel.

Owner:HANGZHOU UNITED TOOLS CO LTD

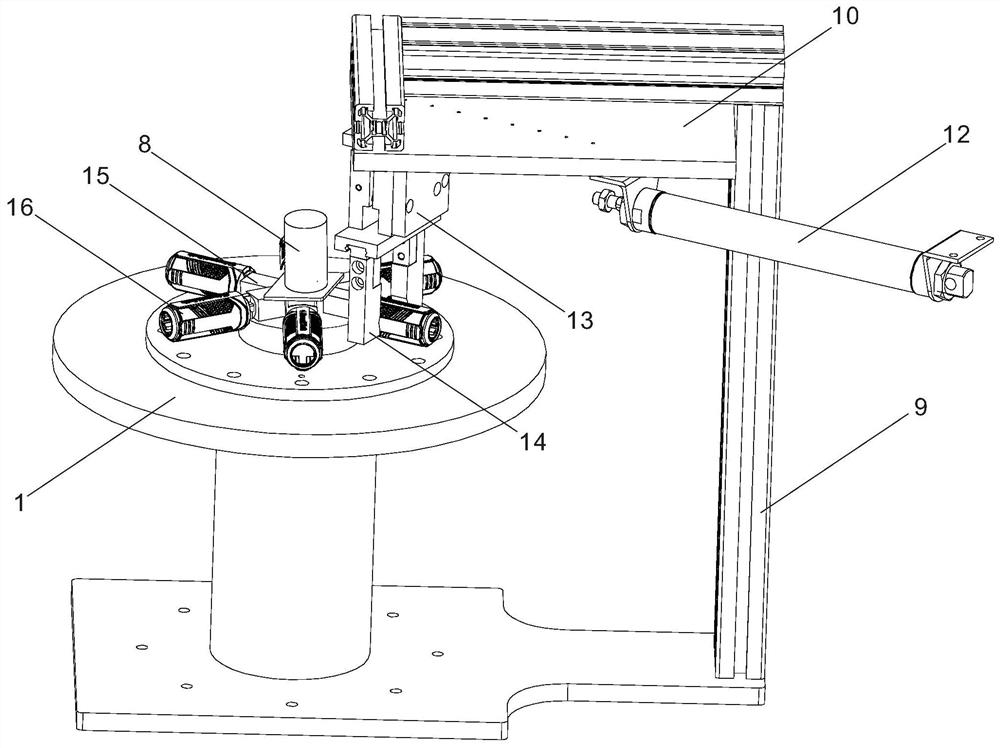

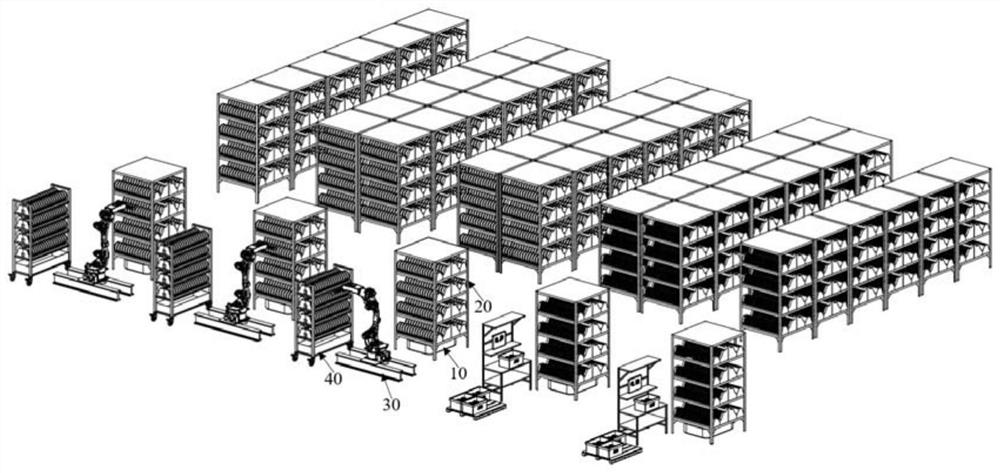

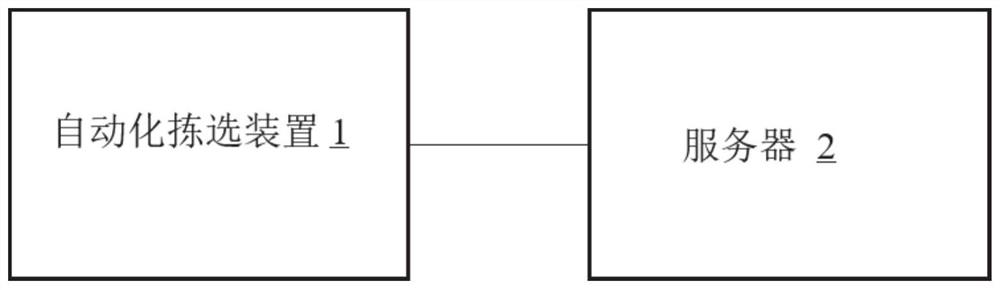

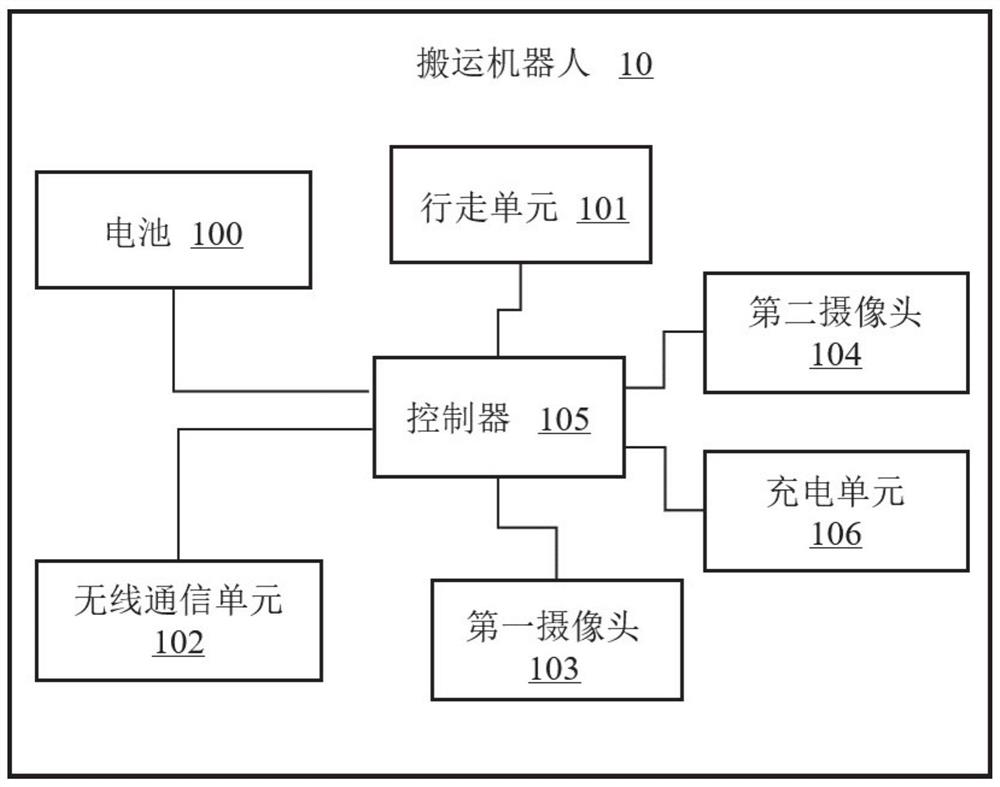

Automatic sorting device, material sorting method and server

ActiveCN114435840AEasy to shipGuaranteed to be correctStorage devicesTotal factory controlRobot handEmbedded system

The invention discloses an automatic sorting device which comprises a carrying robot, an intelligent material frame, a picking robot and an intelligent skip car. The carrying robot is used for receiving the navigation path sent by the server and navigating to the initial position of the intelligent material rack according to the navigation path, and the carrying robot is further used for carrying the intelligent material rack to the picking station and returning the in-place state information of the intelligent material rack to the server; and the picking robot is used for receiving a clamping task instruction sent by the server, controlling the manipulator to clamp materials from the intelligent material rack according to the clamping task instruction, and putting the materials into the intelligent skip car. The invention further provides a material sorting method and a server, and the storage automation operation capacity and efficiency can be improved.

Owner:准时达国际供应链管理有限公司

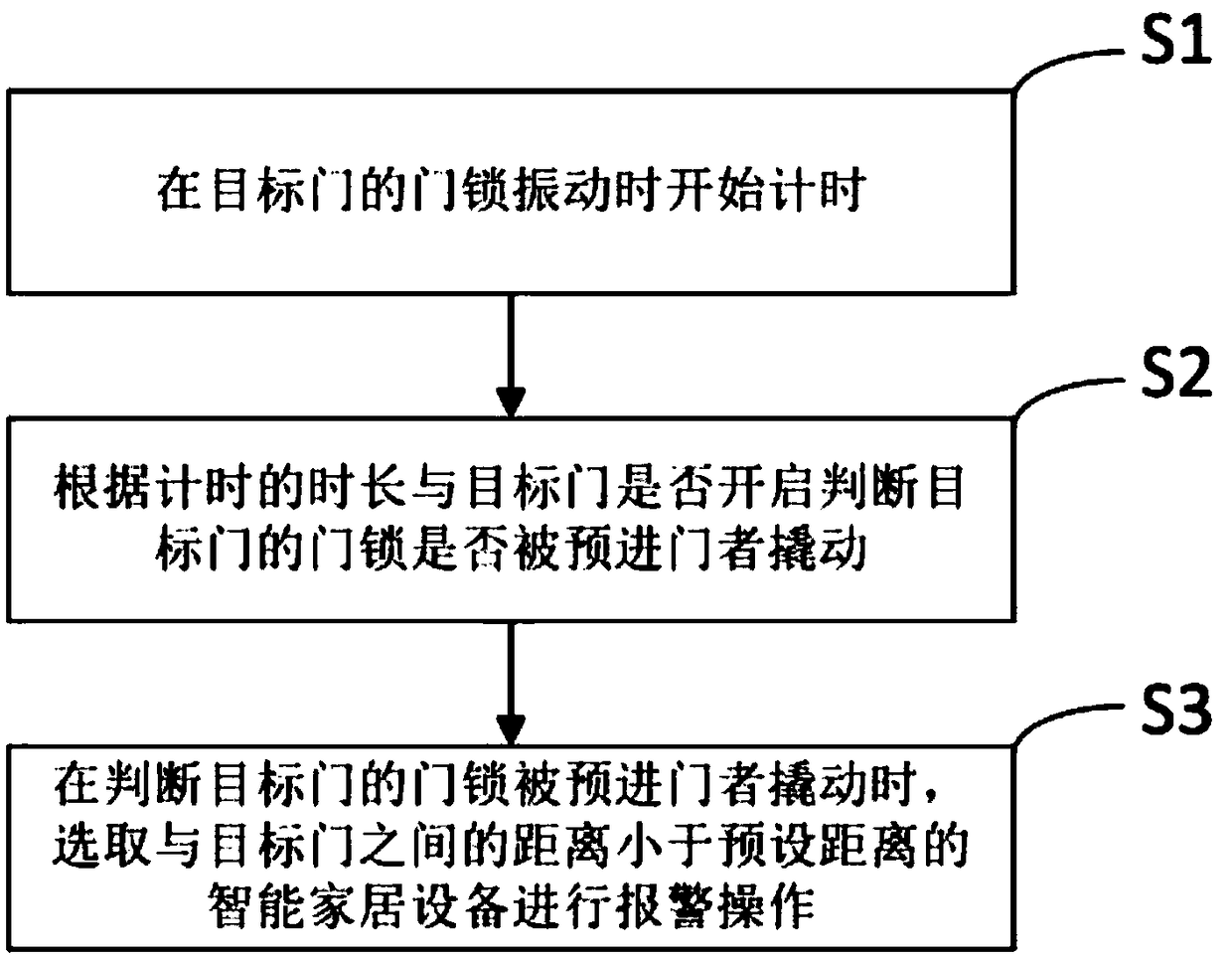

Door prying prevention method based on vibration duration

InactiveCN109035652AAvoid safety hazardsImprove intelligenceTelevision system detailsColor television detailsAutomationElectrical and Electronics engineering

The invention discloses a door prying prevention method based on vibration duration. The door prying prevention method based on vibration duration comprises the following steps that timing is startedwhen a door lock of a target door vibrates; whether the door lock of the target door is pried or not by a pre-entrant is judged according to the timing duration and whether the target door is opened or not; and when the door lock of the target door is pried by the pre-entrant, intelligent household equipment with a distance smaller than a preset distance from the target door is selected for alarmoperation. When it is detected that the vibration duration of the door lock meets the preset condition and the door is not opened, a safety alarm is carried out through the intelligent household, andan image of the pre-entrant is shot at the same time, so that potential safety hazards brought to residents in the door caused by criminals breaking the door by picking the lock are avoided, the intelligence of the home is improved, the automation effect among different homes is enriched, and the user experience is further improved.

Owner:ANHUI PIONEER DOOR IND TECH

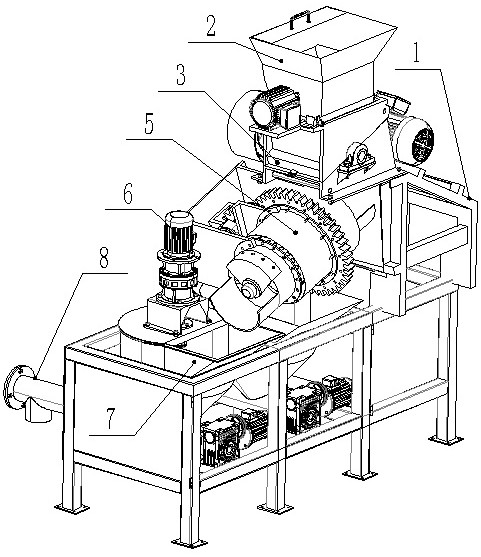

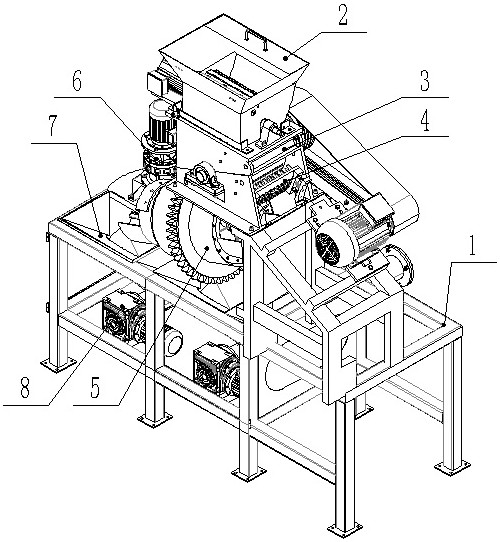

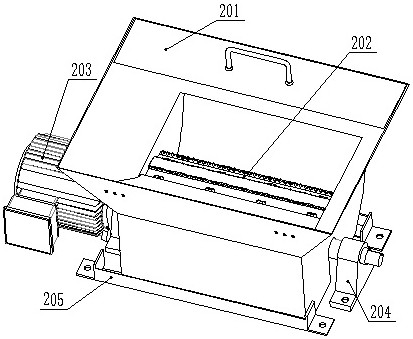

Sweet potato starch extraction device

ActiveCN112221668AGuaranteed crushing speedContinuously workingGrain treatmentsFood scienceChipped potatoesPotato starch

The invention discloses a sweet potato starch extraction device. The extraction device comprises a frame body, a grinding crushing device, a smashing device, an anti-blocking mechanism, a screening removing device, a stirring crushing device, a receiving hopper and a forming device; multiple rows of teeth are arranged in the grinding crushing device, so that the grinding crushing speed of sweet potatoes is guaranteed, working is continuous, and the working efficiency is improved; the ground and crushed sweet potato blocks enter the smashing device, are smashed and then enter the screening removing device; and through filtering of the screening removing device, sweet potato pulp is directly recycled into the forming device through the receiving hopper, small-particle sweet potato chips enter the stirring crushing device to be processed again and then are output into the forming device to be subjected to starch extraction, interference of the external environment is avoided, and the product quality is high. According to the extraction device, sweet potatoes are thoroughly smashed through multiple processes, the maximum starch extraction amount is achieved, the automation effect is sufficient, and the problems of low automation degree and starch quality of manual operation are solved.

Owner:张家界朝阳冲农产品开发有限责任公司

Ammonium oil explosives delivery method and ammonium oil explosives on-site mixing method

ActiveCN111637805BExpand the scope of automatic charging operationsAvoid manual handlingExplosive working-up apparatusBlastingExplosive AgentsProcess engineering

The application relates to an ammonium oil explosive delivery method and an ammonium oil explosive on-site mixing method, belonging to the technical field of explosive mixing. A method for delivering ammonium oil explosives, comprising: feeding compressed gas into a storage container to transport the ammonium oil explosives in the storage container to a delivery channel. The compressed gas is fed intermittently into the delivery channel to divide the ammonium oil explosive in the delivery channel into slugs and transported to predetermined positions along the delivery channel. The pneumatic pulse transmission is used for long-distance transportation, which expands the scope of on-site automatic charging of ammonium oil explosives, and is especially suitable for use under complex on-site conditions. It avoids on-site bagging and manual handling, and improves the automatic operation capability.

Owner:BEIJING BGRIMM YIBO TECH +1

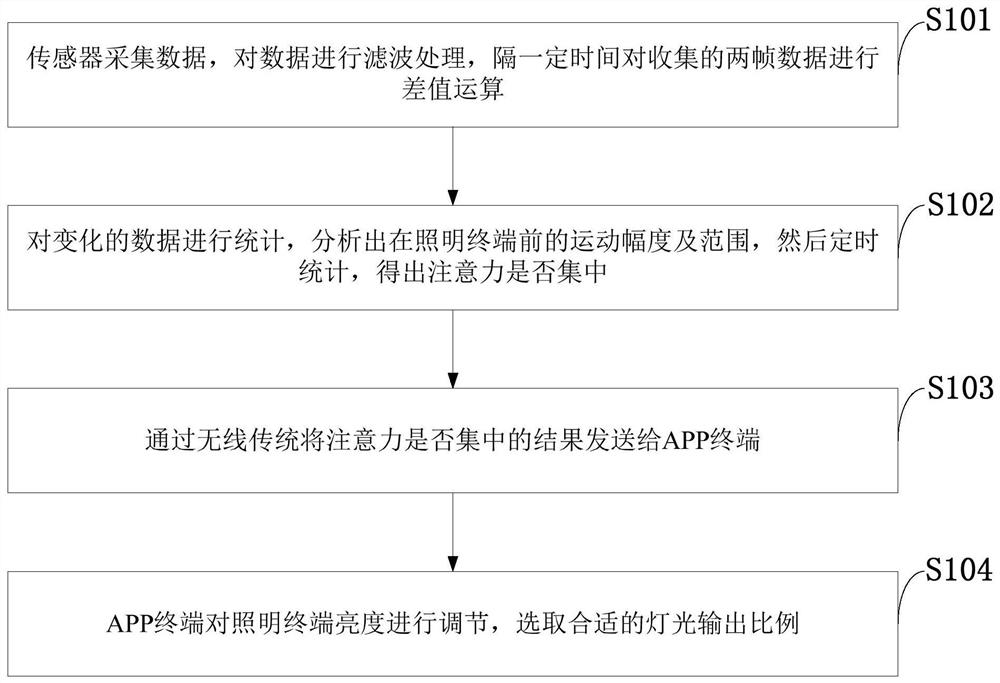

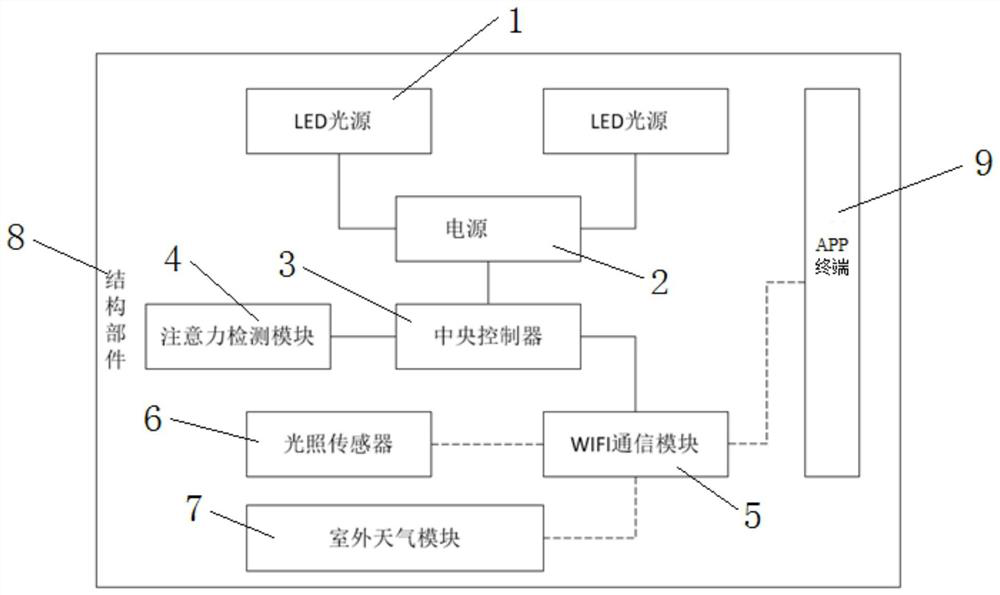

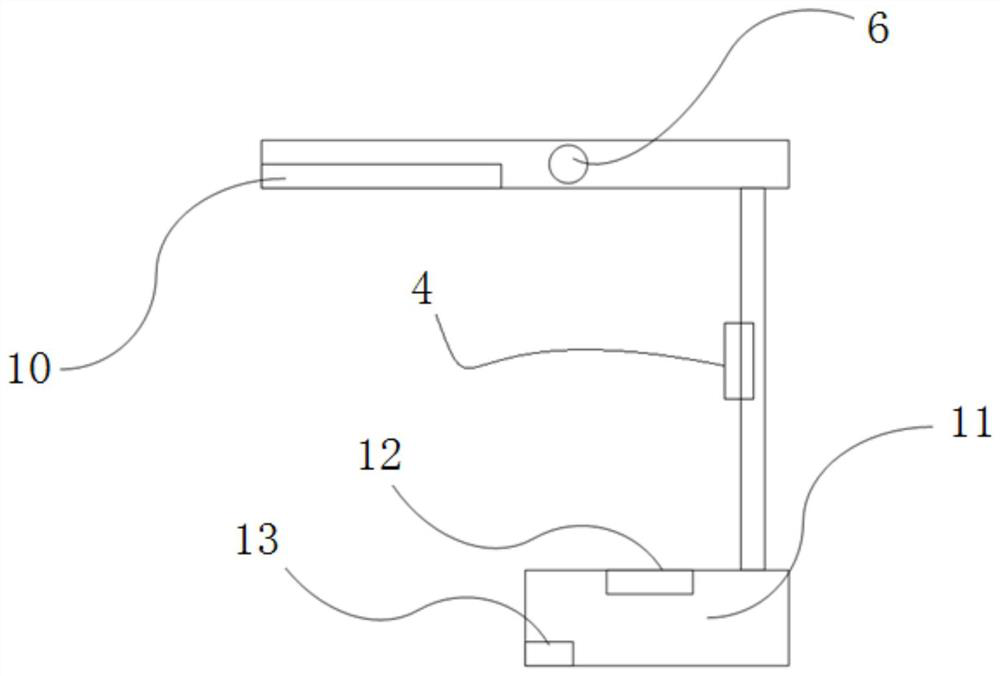

Lighting control method and system, storage medium, lighting terminal and table lamp

InactiveCN113853044AImprove lighting experienceImprove automation capabilitiesElectrical apparatusEnergy saving control techniquesLighting systemEngineering

The invention belongs to the technical field of intelligent lighting control, and discloses a lighting control method and system, a storage medium, a lighting terminal and a table lamp. According to the environment condition of the position of a user, the weather condition of the position and the time factor in the using process of the table lamp, filtering processing, difference value operation and data statistics are carried out on data, the change amplitude, range and change mode in front of the lighting terminal are analyzed, and the light output proportion is determined to automatically adjust the lighting light output state. According to the environment condition of the position where the user is located, the weather condition of the position where the user is located, the time in the table lamp using process and other factors, the lighting lamplight output state is automatically adjusted, the requirements of the user are intelligently responded, the lighting experience of the user using the table lamp is improved, the automation capacity of the table lamp is improved, and intelligence of the table lamp lighting system is realized.

Owner:马嘉腾

An elevator system with a three-level monitoring network

The invention provides an elevator system with a three-level monitoring network. By the arrangement of the monitoring network with a three-level structure and an intelligent control device connected with the monitoring network in a communicated mode, an Internet of Things around an elevator is constructed, and therefore elevator operation environment is comprehensively monitored from multiple degrees, and the safety of the elevator is significantly improved. Besides, the elevator system is also capable of shooting a user video, responds to an image acquisition instruction sent by the user, acquires user images, matches the user images according to the acquired user images, and therefore a user identity is determined; according to the user identity, the destination floor which the user needs to go is obtained, and therefore a control instruction is automatically sent to a lift car to control the lift car to move to the destination floor, the user's operation is saved, and the function that users' destinations are determined automatically is achieved. The automated operation capacity of the elevator is significantly improved, the designated action of user conventional destinations is saved, and the user's experience is improved.

Owner:北菱电梯股份有限公司

Method for testing unmanned vehicles with moving targets on the road

ActiveCN112444402BImprove automation capabilitiesImprove drive test efficiencyVehicle testingElectric machineryRoad surface

The method of testing unmanned vehicles with moving targets on the road belongs to the field of unmanned vehicle road test experiments. In order to solve the problem of simulating the running track of moving targets while driving unmanned vehicles, the problem of presenting a variety of road test scenarios with different driving trajectories , fix the cap of the moving target on the deck of the roller trolley, start the device, the motor starts to run, the motor on the left side of the road tightens the rope, the motor on the right loosens the rope, and controls the contraction of the rope, thereby controlling the roller trolley carrying the moving target And make it run on the road test road, the effect is to provide as many test scenarios as possible for driverless cars.

Owner:DALIAN NATIONALITIES UNIVERSITY

Automatic trimming method for stamping die

PendingCN114713688AShorten the production cycleIncrease productivityShaping toolsMetal-working feeding devicesStampingStructural engineering

The invention relates to the technical field of stamping processing equipment, and discloses an automatic trimming method for a stamping die, which comprises a supporting box body, the inner side of the middle part of the supporting box body is fixedly sleeved with a rotary positioning mechanism, the top surface of the rotary positioning mechanism is fixedly provided with a lower stamping die, and the lower stamping die is internally and movably sleeved with a workpiece; the two sides of the top face of the workpiece are movably connected with constant pressure mechanisms, the bottom faces of the constant pressure mechanisms are fixedly connected to the top face of the middle of the supporting box body, a lower pressing sleeve is arranged at the top of the workpiece, and the inner side of the top of the lower pressing sleeve is fixedly connected with an upper stamping die in a sleeved mode. According to the automatic edge cutting device for the stamping die and the edge cutting method of the automatic edge cutting device, through mutual cooperation of the constant pressure mechanism, the adjusting composite box body, the edge cutting mechanism and the advancing mechanism, redundant materials of a workpiece are subjected to automatic edge cutting operation after the workpiece is stamped, the integrated stamping and edge cutting machining technology is achieved, the production cycle of the workpiece is shortened, and the production efficiency is improved.

Owner:赣州佳广智能装备科技有限公司

Slicing device for home life

InactiveCN109605459AImprove automation capabilitiesReduce labor outputMetal working apparatusEngineeringMechanical engineering

The invention discloses a slicing device for home life. The slicing device for home life comprises a pressure hydraulic cylinder, a food pressed film and a slicing knife disk, wherein a device tank isarranged on the lower part of a device body; a rotary motor is arranged in the device tank and is connected with the slicing knife disk through a belt; a food placing port is arranged at the upper end of the slicing knife disk; the food pressed film corresponding to the size of the port part is embedded into the food placing port; the back end of a cylinder fixing frame is fixed to the upper endof the device tank through a self support; and the front end of the cylinder fixing frame is fixed to the upper end of the middle position of the device tank at the food placing port through an auxiliary support pillar. According to the slicing device for home life, pressed film limiting blocks are arranged on the side walls of the food pressed film, so that the lowering position of the food pressed film is favorably controlled, the damage on the slicing knife disk caused by excessive food pressed film lowering is effectively prevented, and meanwhile, the slicing knife disk is prevented from damaging the food pressed film.

Owner:GUIZHOU UNIV

Automatic packaging device based on doubling thread cloth roll

ActiveCN113911483AImprove automation capabilitiesReduce power consumptionWrappingBio-packagingPhysicsMechanical engineering

The invention provides an automatic packaging device based on a doubling thread cloth roll, and relates to the technical field of thread roll packaging. The device comprises: a base, wherein an air cylinder is fixedly arranged in the middle of the top of the base, a locking piece is fixedly arranged at the top of the telescopic end of the air cylinder, and the locking piece is a rubber block with the top being an arc-shaped concave surface; and a top seat fixedly arranged at the top of the base through four groups of stand columns. According to the packaging device, an automatic propelling structure, a fixed-point lifting, aligning and packaging structure and an automatic rotating and winding function are provided, and the problems that according to an existing packaging device, spinning thread rolls or cloth rolls need to be packaged through high-power-consumption packaging modes such as cutting and hot melting, packaging losses are large, the automatic packaging function which is rapid, automatic, environment-friendly and labor-saving is not achieved, and automatic feeding is not facilitated to complete packaging are solved.

Owner:宁夏大斌家纺科技有限公司

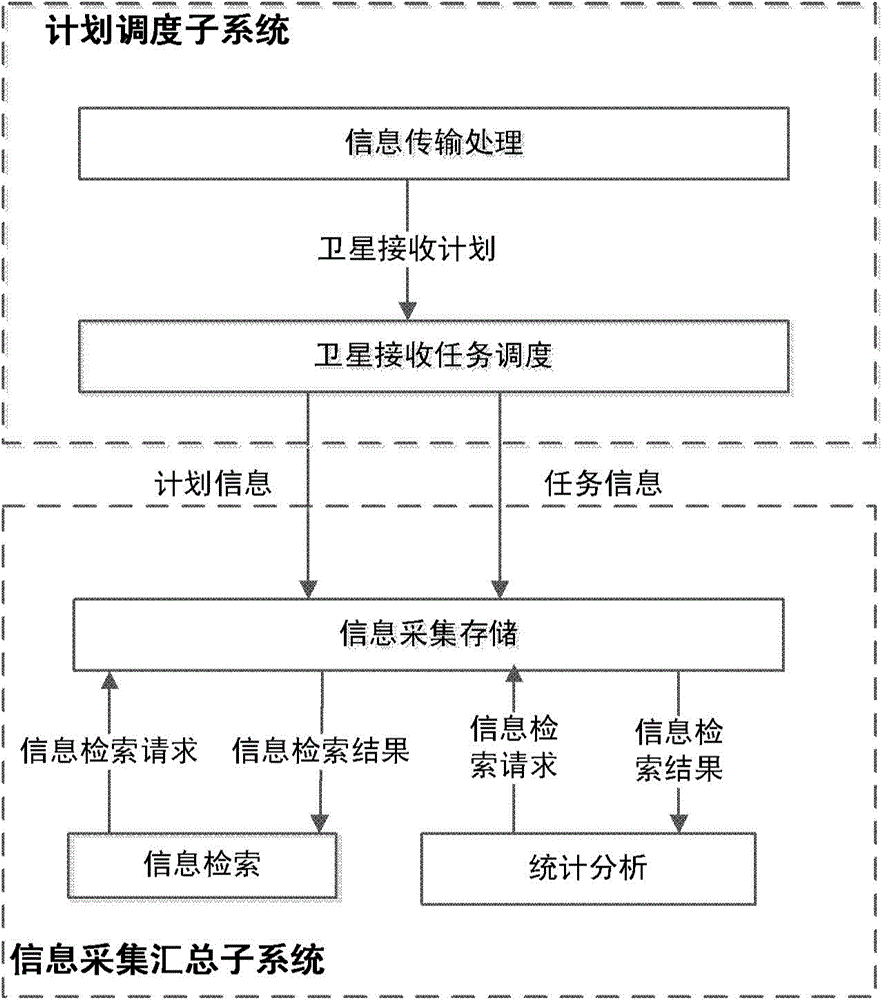

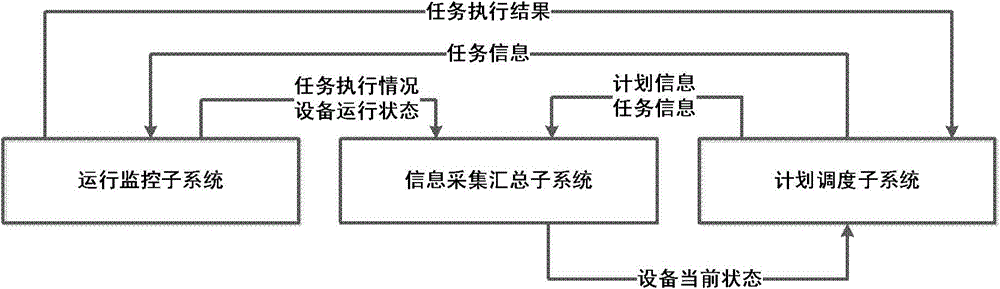

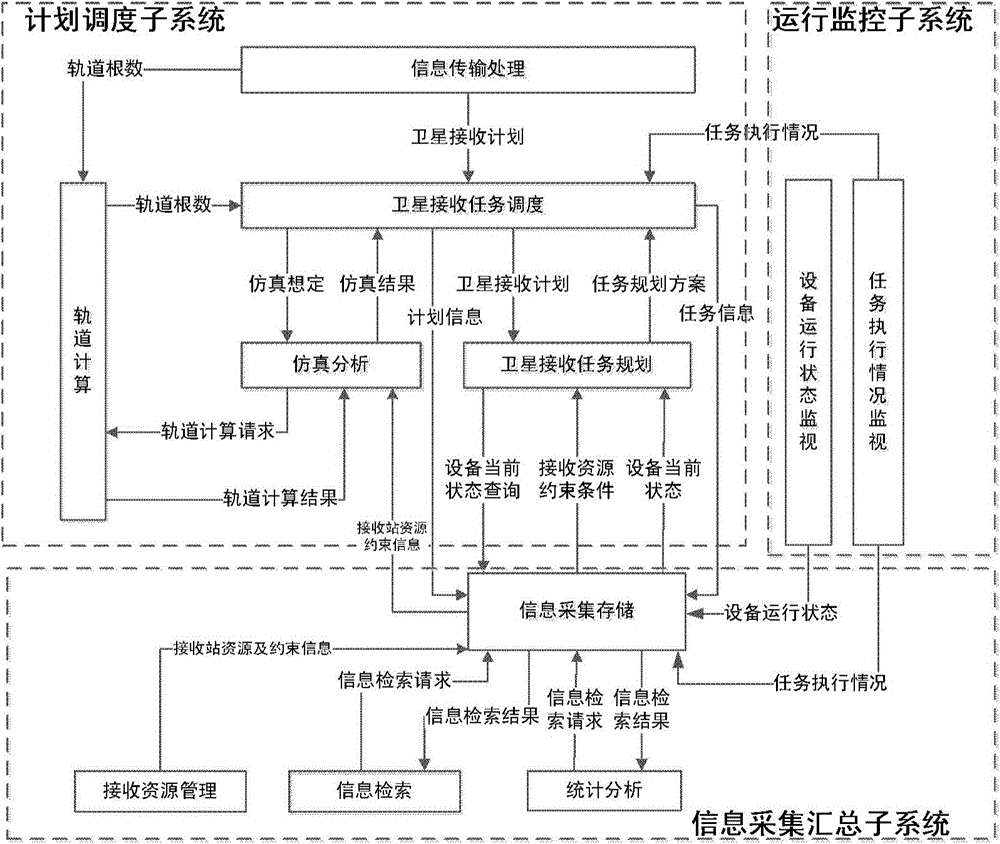

A task planning and dispatching system for ground receiving station network of land observation satellite data

ActiveCN104008443BMeet operational requirementsImprove automation capabilitiesResourcesSatellite dataInformation access

The invention discloses a mission planning and scheduling system of a land observation satellite data ground receiving station network. The system comprises a planning and scheduling subsystem, an operation monitoring and controlling subsystem and an information collecting and summarizing subsystem, wherein the planning and scheduling subsystem is used for automatically and overall planning and generating satellite data receiving, recording and transmitting missions of receiving stations in the ground receiving station network according to land observation satellite data receiving plans, scheduling and driving receiving and recording devices of the receiving stations to execute the corresponding missions, and scheduling and driving a ground optical fiber data transmission device to execute the corresponding missions; the operation monitoring and controlling subsystem is used for monitoring the executive conditions of all the missions and device operation statuses in the ground receiving station network in real time; the information collecting and summarizing subsystem is used for collecting and summarizing mission information and monitoring information of the ground receiving station network, and providing the functions of information access, storage, backup, query and retrieval and statistic analysis. The method solves the problems of conducting integrated and automatic planning, operation monitoring and information collecting and summarizing on the multiple satellite receiving, recording and transmitting missions through the land observation satellite data ground receiving station network.

Owner:中科卫星山东科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com