Automatic packaging device based on doubling thread cloth roll

A technology for automatic packaging and cloth rolls, applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of large loss, no automatic packaging function, unfavorable packaging, etc., to achieve low power consumption, perfect automation effect, Easy plug-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

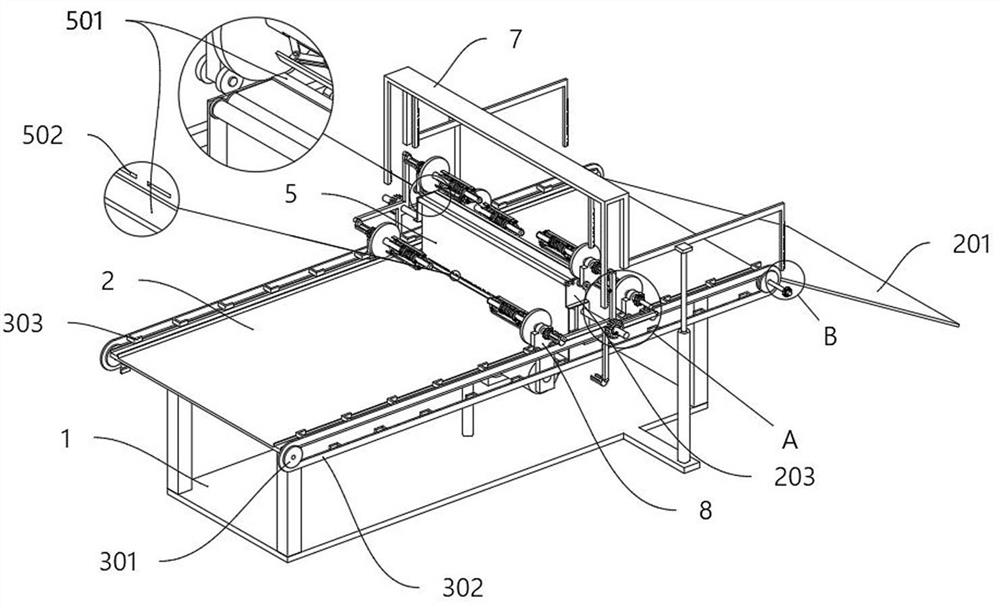

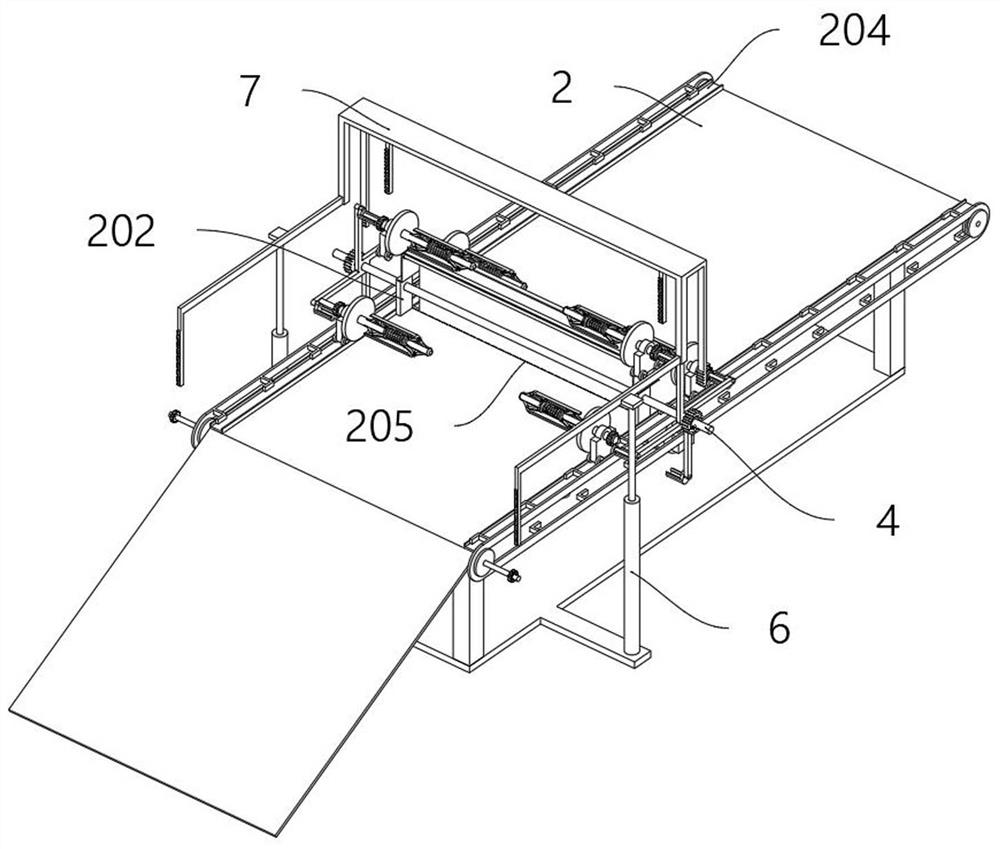

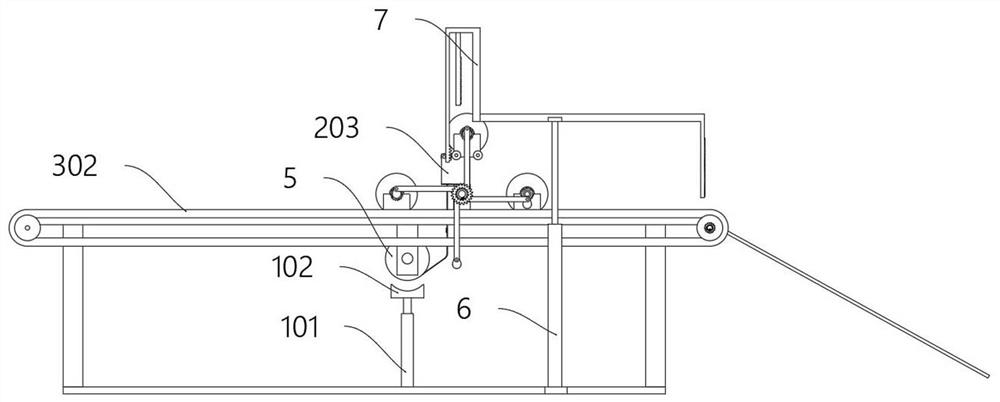

[0035] Example: Please refer to Figure 1 to Figure 8 :

[0036] The present invention proposes an automatic packaging device based on spinning cloth rolls, including: a base 1, a cylinder 101 is fixedly arranged in the middle of the top of the base 1, and a locking member 102 is fixedly arranged on the top of the telescopic end of the cylinder 101, and the locking member 102 is the top A rubber block with an arc-shaped concave surface; the top seat 2, which is fixed on the top of the base 1 through four sets of columns; the top seat 2 includes: a slope plate 201, and the rear side of the top seat 2 is integrally provided with a slope plate 201 ; Pedestal 202, two groups of pedestals 202 are fixedly arranged on the top of the top seat 2, and vertical plates 203 are fixedly installed on the top of pedestal 202; Set on the bottom of the front and rear sides of the top seat 2; the central axis 4, the central axis 4 is rotated and arranged in the shaft frame 202; the packaging fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com