Rail flaw detection vehicle capable of detecting flaws on top surfaces of rails

A technology of rail flaw detection vehicle and detection vehicle, which is applied to railway inspection vehicles, railway car body parts, railway auxiliary equipment, etc. Environmental comfort and the effect of improving automation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

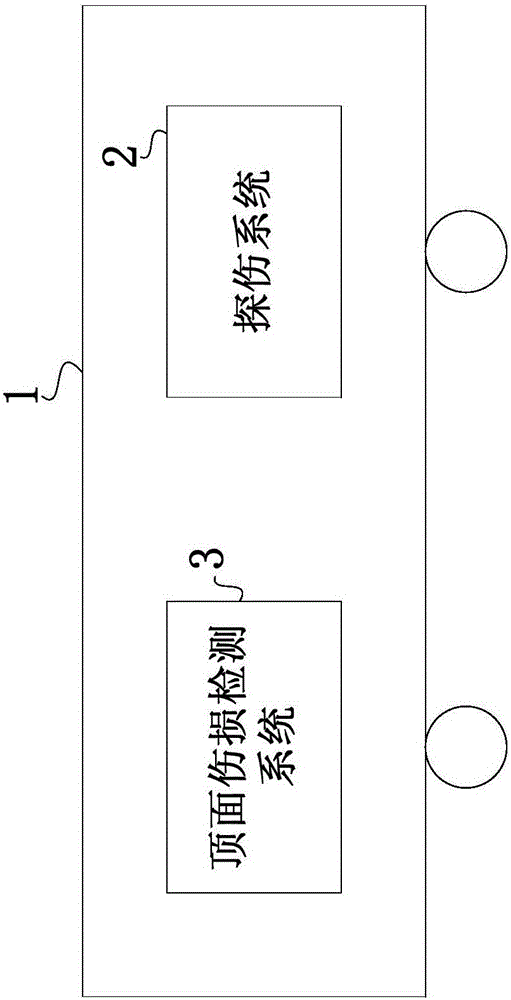

[0022] figure 1 It is a structural schematic diagram of a rail flaw detection vehicle equipped with rail top surface damage detection according to an embodiment of the present invention. like figure 1 As shown, the rail flaw detection car includes: a flaw detection car 1, a flaw detection system 2, and a top surface damage detection system 3; wherein,

[0023] Flaw detection car 1 runs on the steel rails.

[0024] The flaw detection system 2 is installed on the flaw detection vehicle 1 and is used to detect the internal damage of the rail.

[0025] The top surface damage detection system 3 is installed on the flaw detection vehicle 1 and is used to detect the surface and sub-surface damage of the rail head.

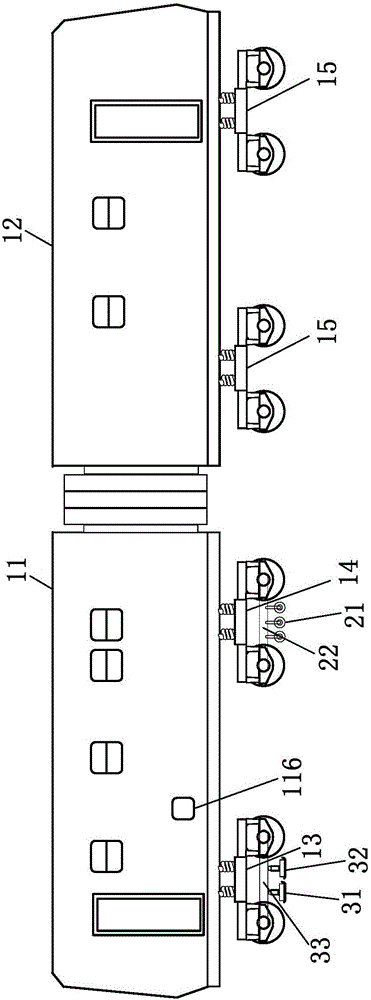

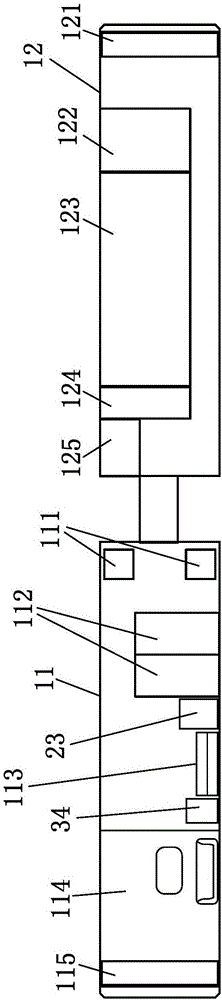

[0026] Further, combine Figure 2 to Figure 5 From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com