Counter-rotating secondary fan silencing system

A rotary and noise reduction technology, applied in non-variable pumps, ventilation of mines/tunnels, mining equipment, etc., can solve problems affecting the ventilation efficiency of fans and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

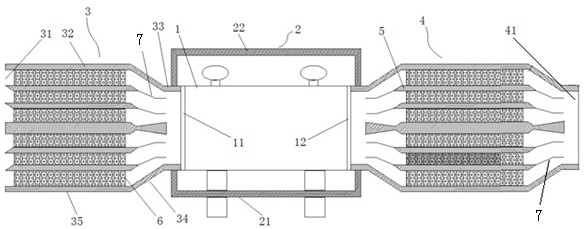

[0021] Such as figure 1 As shown, a counter-rotating local fan silencing system includes a box cover 2 in which the local fan 1 is placed, a cavity-expanding air-inducing muffler 3 installed at the air inlet 11 of the local fan, and a muffler 3 installed at the air outlet 12 of the local fan. The radius of the air inlet 31 of the expanded cavity muffler 3 is greater than the radius of the connection end with the local fan air inlet 11, and the radius of the air outlet end 41 of the expanded cavity muffler is equal to The radius of the connection end with the local fan air outlet 12 is provided with a sound-absorbing layer 5 in the housing inner wall and inner cavity of the enlarged cavity induced wind muffler 3 and the expanded cavity air outlet muffler 4 .

[0022] The distance between different sound-absorbing layers is proportional to the layer thickness of the sound-absorbing layer. The production of the sound-absorbing layer is not arbitrary, and its thickness and length...

Embodiment 2

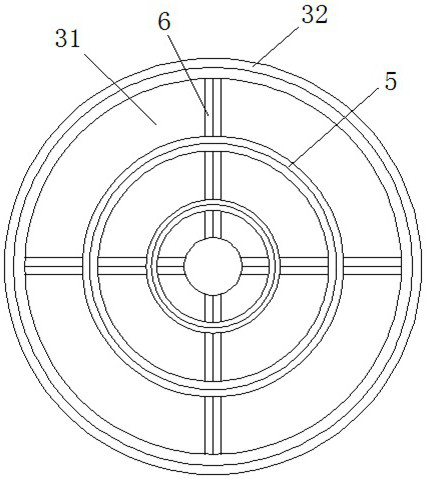

[0027] As a preferred design of Embodiment 1, the cavity-enlarging air-induced wind muffler 3 includes an outer shell 32 with a hollow inner cavity and openings at both ends, and a sound-absorbing layer 5 installed in the hollow inner cavity of the outer shell 32. The outer shell 32 is The sound-absorbing structure inside the outer compartment, the air-enlarging muffler 3 is divided into a connecting section 33, a flared section 34 and a sound-absorbing section 35 connected in sequence, wherein the end of the connecting section 33 is connected to the local fan air inlet 11 through a flange, The flaring section 34 is a conical frustum or a truss, and an air deflector 7 is arranged inside to guide the wind into the muffler section 35. The sound absorbing layer 5 provided in the muffler section 35 is connected with the air deflector 7 correspondingly. Between different sound absorbing layers 5 , and the sound-absorbing layer 5 is connected to the outer casing 32 through the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com