Electrolytic carbon electrode plane cleaning roller and cleaning machine with electrolytic carbon electrode plane cleaning rollers

A technology for cleaning rollers and extremely flat surfaces, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., to achieve the effect of improving comfort, reducing personnel operations, and high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific content of the present invention is further described below:

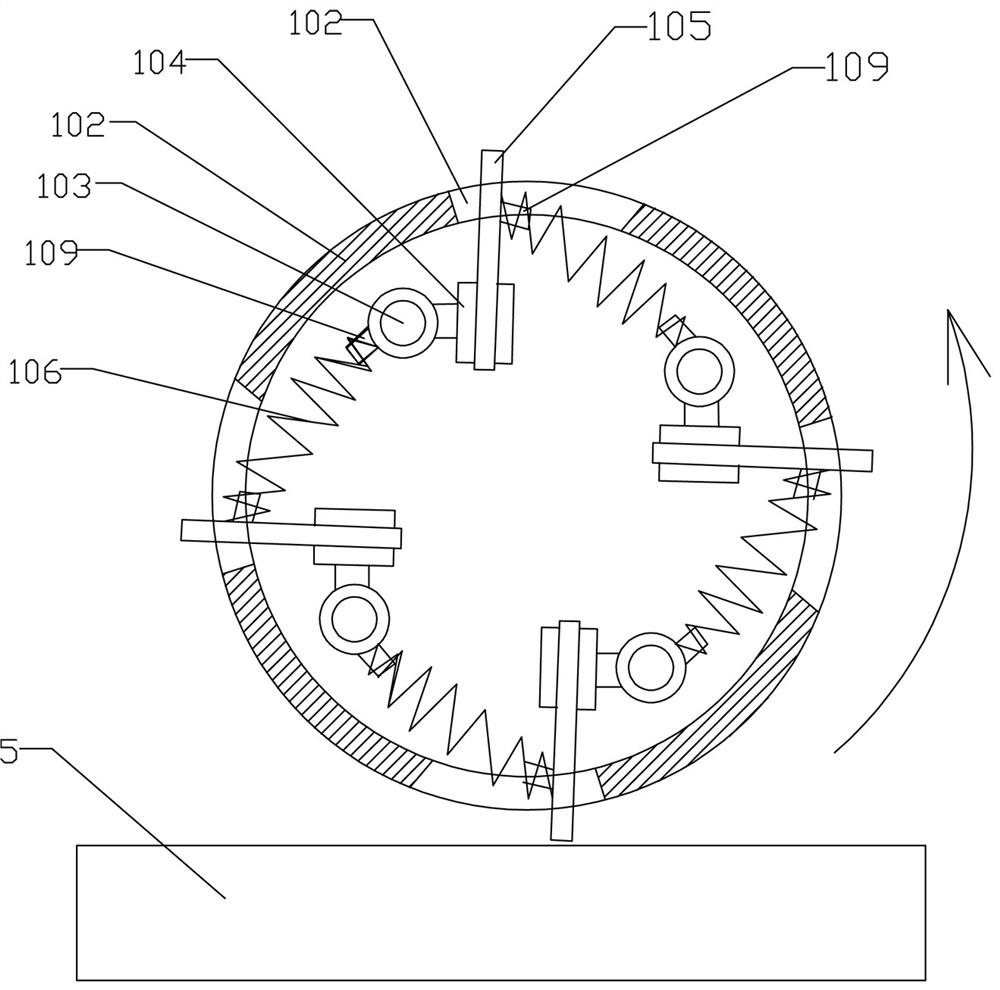

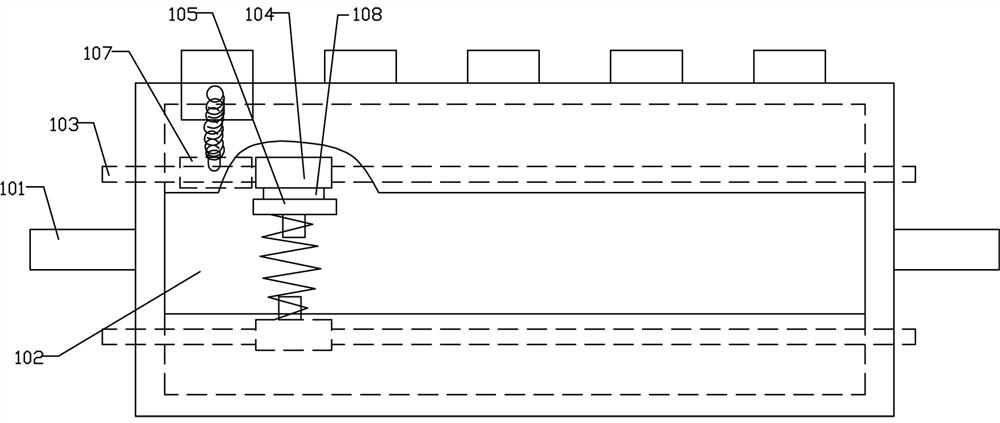

[0028] The electrolytic carbon pole plane cleaning roller of the present invention has a structure such as figure 1 and figure 2 As shown in , the cleaning roller is a columnar cylindrical metal structure, both ends are plugged end faces, and a rotating drive shaft 101 is arranged on the plugged end faces. Four strip rectangular through grooves 102 are arranged on the peripheral surface, and the through grooves 102 run through the inner and outer spaces of the cleaning roller. The cleaning roller is provided with a scraper shaft 103 between the two through grooves, and the scraper shaft 103 is parallel to the rotation center of the cleaning roller.

[0029] One scraper shaft 103 is provided with a scraper fixing frame 104 and a pressure spring positioning sleeve 107 at intervals, and the other scraper shaft 103 is provided with a compression spring positioning sleeve 107 and a scraper fixing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com