Large scrap steel processing and distribution center factory and workshop arrangement mode

A distribution center and workshop layout technology, applied in the direction of solid waste removal, instruments, manufacturing computing systems, etc., can solve the problems of increasing operating costs, increasing logistics costs, wasting land resources, etc., to achieve convenient logistics and equipment utilization rate High, the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

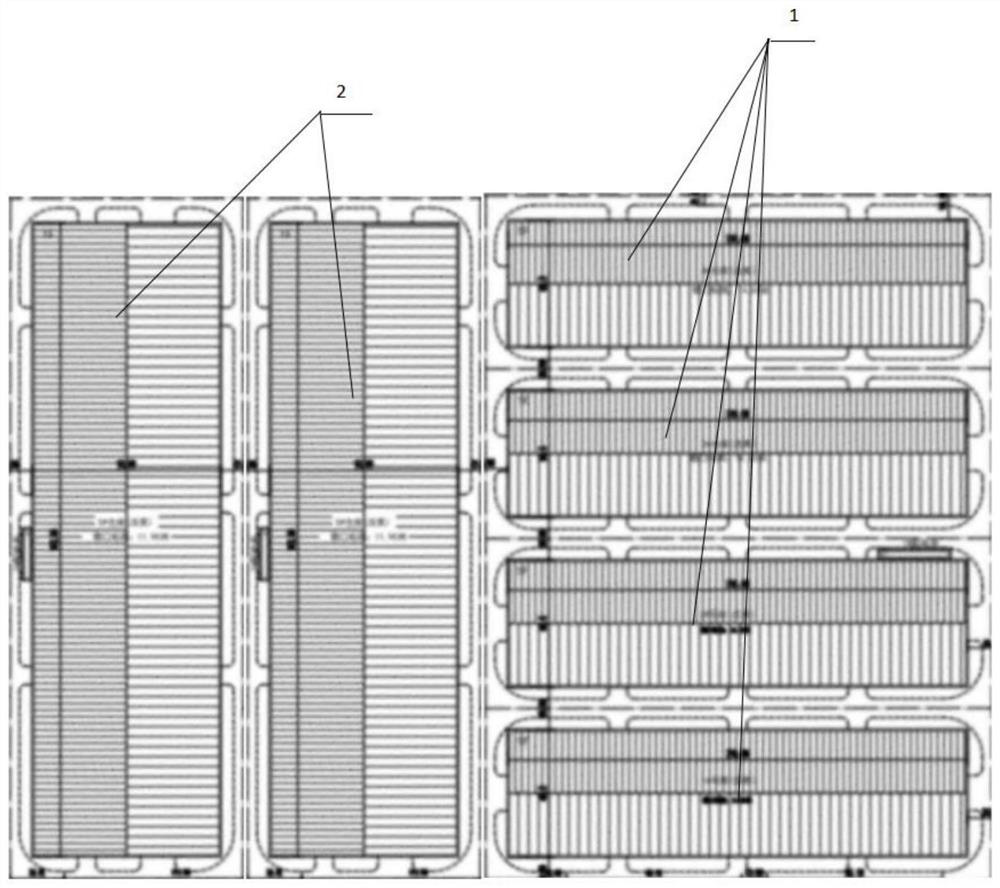

[0034] The scrap steel processing and distribution base of the present invention has an annual processing capacity of 3-4 million tons and covers an area of about 300 mu. It can be seen from Fig. 1 that the workshop layout of the scrap steel processing and distribution center in the present invention is as follows: the scrap steel processing and distribution center workshop is arranged near the port or the transportation distribution center, close to the big customers who use scrap steel, and the scrap steel processing and distribution center workshop includes sorting Workshop 1 and cutting and packaging workshop 2, the sorting workshop 1 is provided with more than 3 rooms arranged horizontally, and the shearing and packaging workshop 2 is provided with more than 1 room arranged longitudinally along one side or both sides of the sorting workshop 1, and the workshops are The rectangle, the four sides and the ceiling are all closed. Logistics channels are arranged around the wo...

Embodiment 2

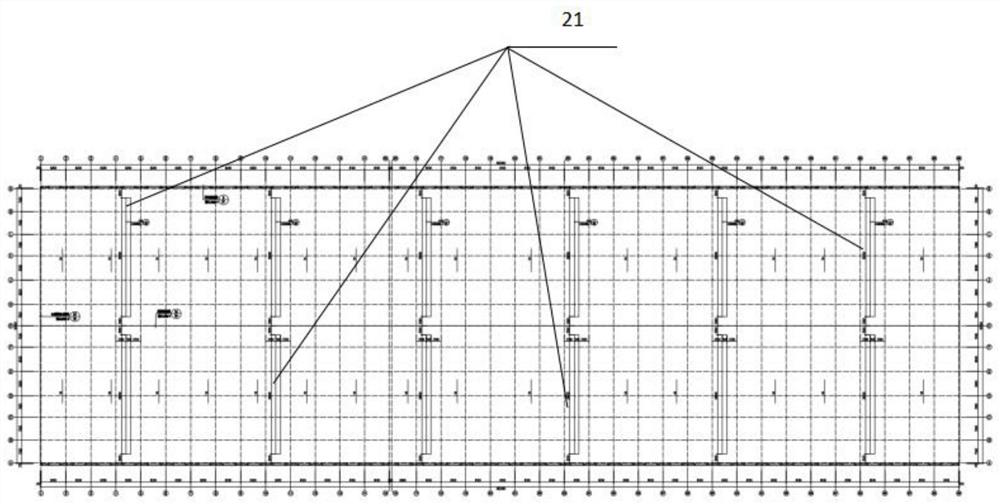

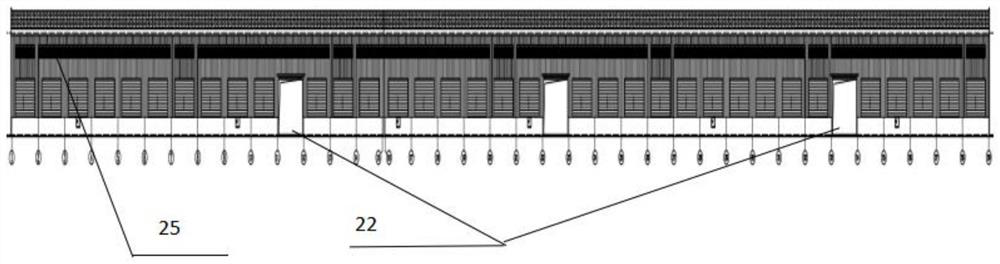

[0036] Depend on figure 1 , 2 , 3, 4, and 5, it can be seen that the sorting workshop 1 is provided with 4 horizontally arranged rooms, and the shearing and packaging workshop 2 is provided with 2 rooms arranged longitudinally along one side or both sides of the sorting workshop 1, and the described workshop is a rectangle with four sides and the ceiling are closed and set, roads are arranged around the workshop and between each workshop, and weighbridges are installed outside the cutting and packaging workshop 2 and the sorting workshop 1. The sorting workshop 1 is 218 meters long, 60.5 meters wide, and the cornice elevation is 14.65 meters. The cutting and packaging workshop 2 is 302 meters long, 90.5 meters wide, and the cornice elevation is 11.95 meters. The sorting workshop 1 and the cutting and packaging workshop 2 are provided with 3 doors on both sides of the long side, the sorting workshop 1 is provided with 2 doors in the width direction, and the cutting and packag...

Embodiment 3

[0038] Depend on figure 1 , 2 , 3, 4, 5, and 9, it can be seen that the sorting workshop 1 is provided with 4 horizontally arranged rooms, and the shearing and packaging workshop 2 is provided with 2 rooms longitudinally arranged along one side or both sides of the sorting workshop, and the described workshops are rectangular, The four sides and the ceiling are all closed, and roads are arranged around the workshop and between each workshop, and weighbridges are installed outside the cutting and packaging workshop 2 and the sorting workshop 1. The sorting workshop 1 and the cutting and packaging workshop 2 are provided with 3 doors on both sides of the long side, the cutting and packaging workshop 2 is provided with 3 doors on both sides of the width direction, and the sorting workshop 1 is provided with 2 doors on both sides of the width direction. . The sorting workshop is 218 meters long, 60.5 meters wide, and has a cornice elevation of 14.65 meters. The cutting and pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com