Automatic vertical drying and curing box for metal composite curtain wall plate

A technology of metal composite and curtain wall panels, which is applied in the direction of surface pretreatment, device for coating liquid on the surface, coating, etc., which can solve the problems of poor drying effect and poor work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

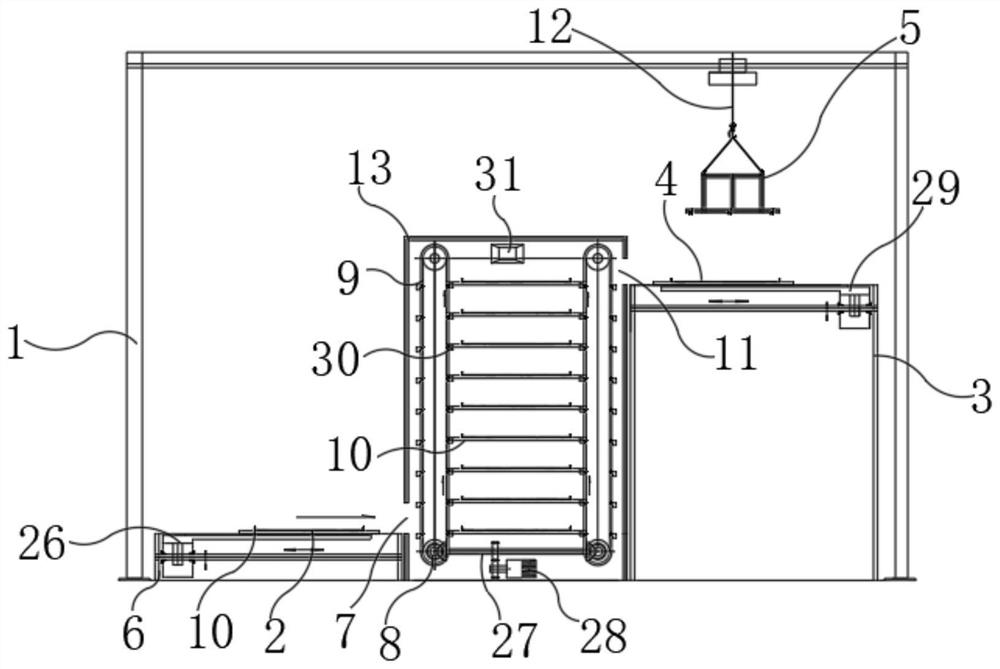

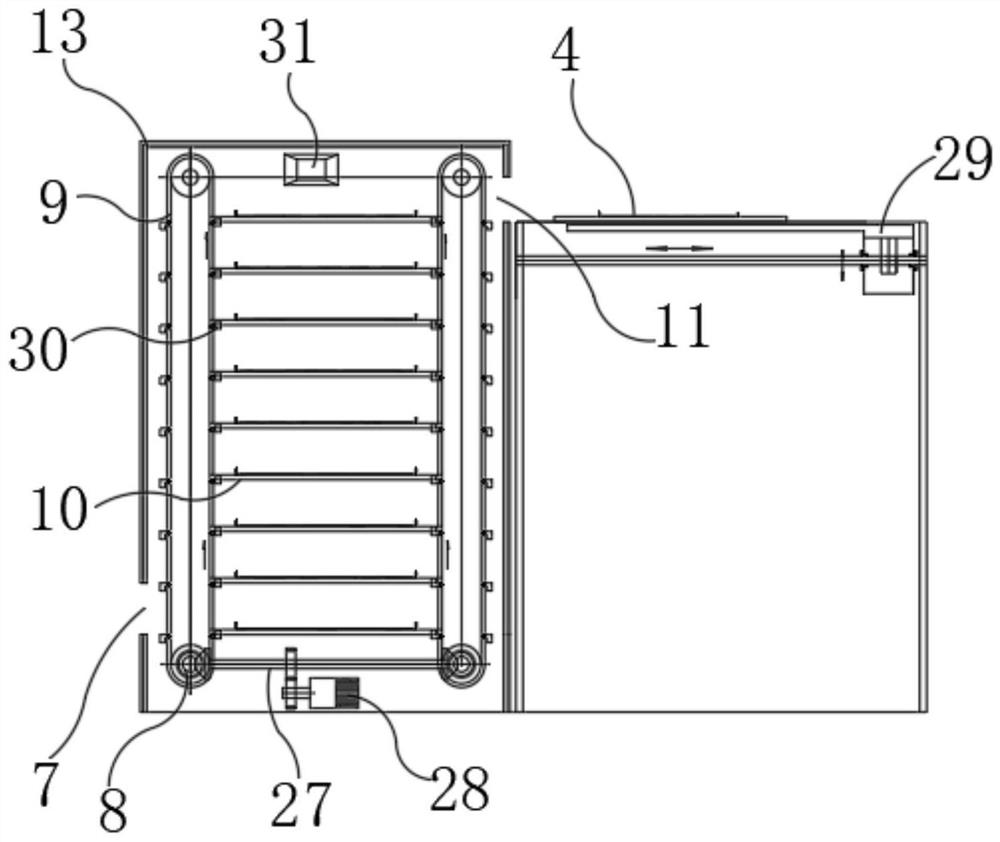

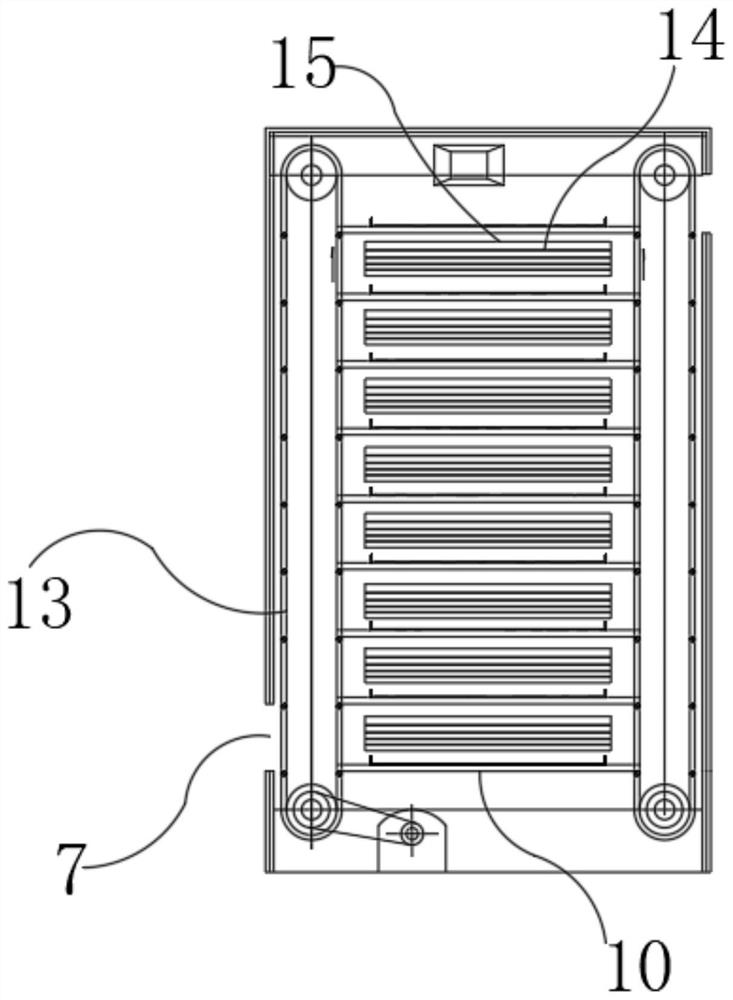

[0032] Such as Figure 1-4 As shown, the metal composite curtain wall panel automatic vertical drying and curing box includes a device main body 1, and the bottom of the device main body 1 is sequentially installed with a feeding workbench 6, a vertical hot air oven 13, a high discharge platform 3, and a vertical hot air oven 13 The lower end of one side of the vertical hot air oven 13 is provided with a feed inlet 7, and the upper end of the other side of the vertical hot air oven 13 is provided with a discharge port 11. The inner two sides of the vertical hot air oven 13 are equipped with a closed sprocket 9, and the closed sprocket 9 is provided with a Positioning pin 30 is arranged, and reducer 28 is installed on the bottom of vertical hot air oven 13, and the output end of reducer 28 is provided with drive shaft 27, and the position that the output end of drive shaft 27 is connected with closed sprocket 9 is equipped with gear 8, feeds The inboard of workbench 6 is provid...

Embodiment 2

[0039] On the basis of Example 1, as Figure 1-4 As shown, the metal composite curtain wall panel automatic vertical drying and curing box includes a device main body 1, and the bottom of the device main body 1 is sequentially installed with a feeding workbench 6, a vertical hot air oven 13, a high discharge platform 3, and a vertical hot air oven 13 The lower end of one side of the vertical hot air oven 13 is provided with a feed inlet 7, and the upper end of the other side of the vertical hot air oven 13 is provided with a discharge port 11. The inner two sides of the vertical hot air oven 13 are equipped with a closed sprocket 9, and the closed sprocket 9 is provided with a Positioning pin 30 is arranged, and reducer 28 is installed on the bottom of vertical hot air oven 13, and the output end of reducer 28 is provided with drive shaft 27, and the position that the output end of drive shaft 27 is connected with closed sprocket 9 is equipped with gear 8, feeds The inboard of...

Embodiment 3

[0043] On the basis of embodiment one and embodiment two, such as Figure 1-6 As shown, the metal composite curtain wall panel automatic vertical drying and curing box includes a device main body 1, and the bottom of the device main body 1 is sequentially installed with a feeding workbench 6, a vertical hot air oven 13, a high discharge platform 3, and a vertical hot air oven 13 The lower end of one side of the vertical hot air oven 13 is provided with a feed inlet 7, and the upper end of the other side of the vertical hot air oven 13 is provided with a discharge port 11. The inner two sides of the vertical hot air oven 13 are equipped with a closed sprocket 9, and the closed sprocket 9 is provided with a Positioning pin 30 is arranged, and reducer 28 is installed on the bottom of vertical hot air oven 13, and the output end of reducer 28 is provided with drive shaft 27, and the position that the output end of drive shaft 27 is connected with closed sprocket 9 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com