Drying device using gas as heating source

A drying device and heating source technology, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of unstable quality, high production cost, air bubbles, etc., and achieve good drying effect and product quality. The effect of improving and heating up quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

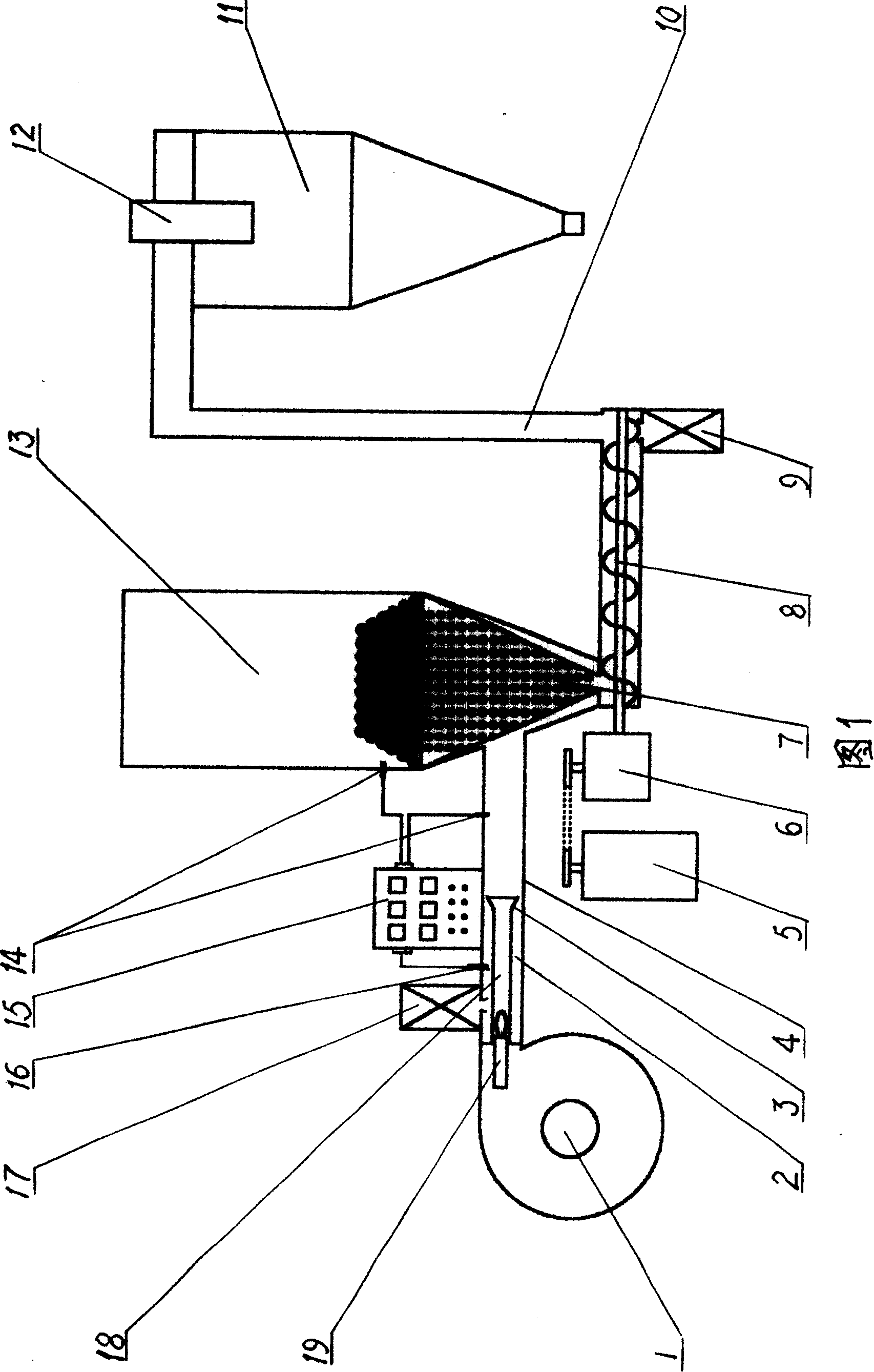

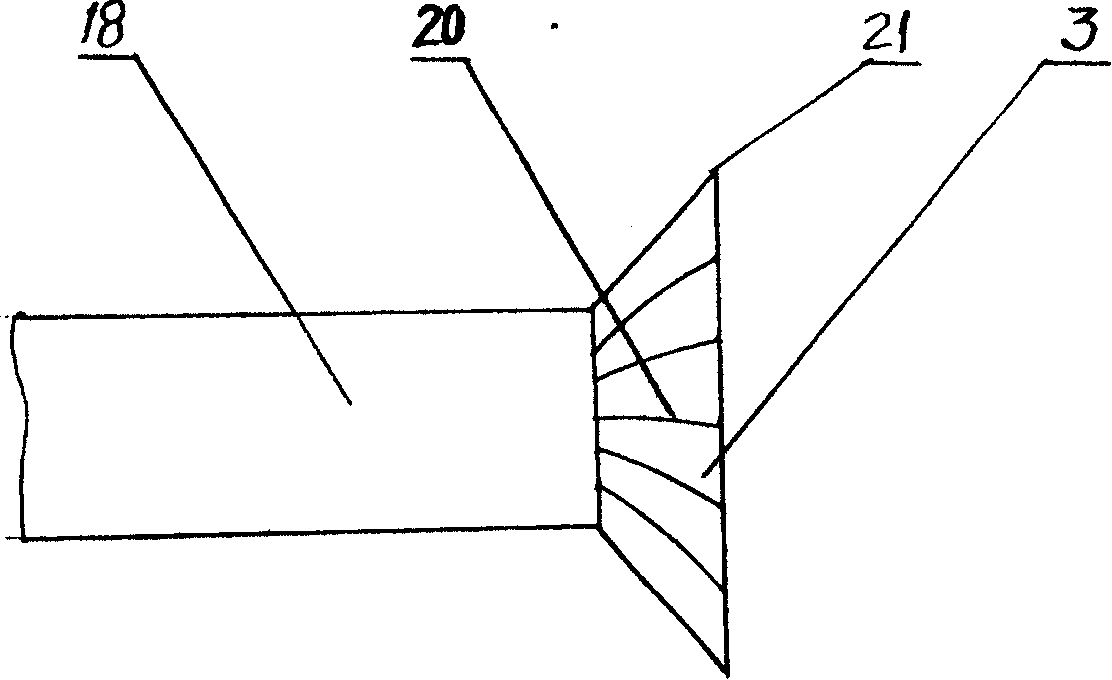

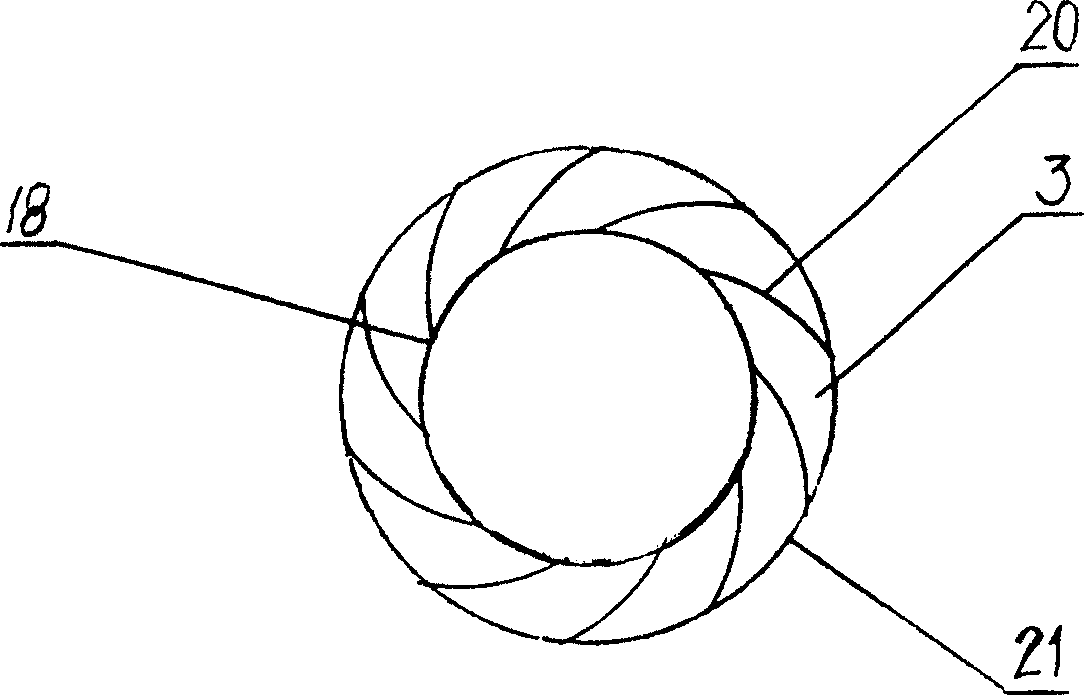

[0019] With reference to a kind of drying device with gas as heating source shown in accompanying drawing 1, comprise raw material drying bin 13, the lower end of this bin is cone-shaped, and the upper end is a feeding port, and the cone of this bin is fixedly connected with Hot air supply system, the hot air uses the gas medium as the heating source. The hot air supply system consists of a gas burner, blower 17, air guide tube 4 and electric control box 15, one end of the air guide tube 4 is fixedly connected to the gas burner, and the other end of the air guide tube 4 is fixedly connected to the raw material drying bin 13 , the blower 17 and the electric control box 15 are fixedly connected on the outside of the air guide tube 4, the outer surface of the air guide tube 4 is wrapped with thermal insulation material, and the lower end cone of the raw material drying storehouse 13 is fixedly connected with a raw material delivery system. The raw material drying bin 13 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com