Extraction device and method for recycling phosphorus in sludge incineration ash

A technology for sludge incineration and ash, which is applied in the direction of separation methods, chemical instruments and methods, phosphate, etc., can solve the problems of unreasonable utilization of phosphate, and achieve the goal of improving the effect of automatic operation, reducing production costs, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

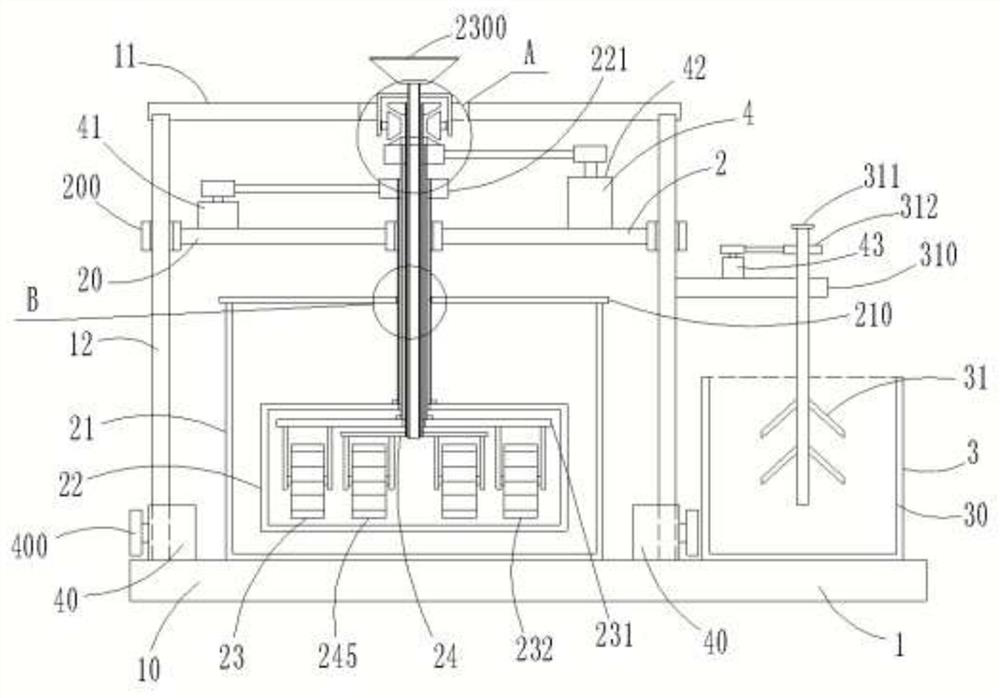

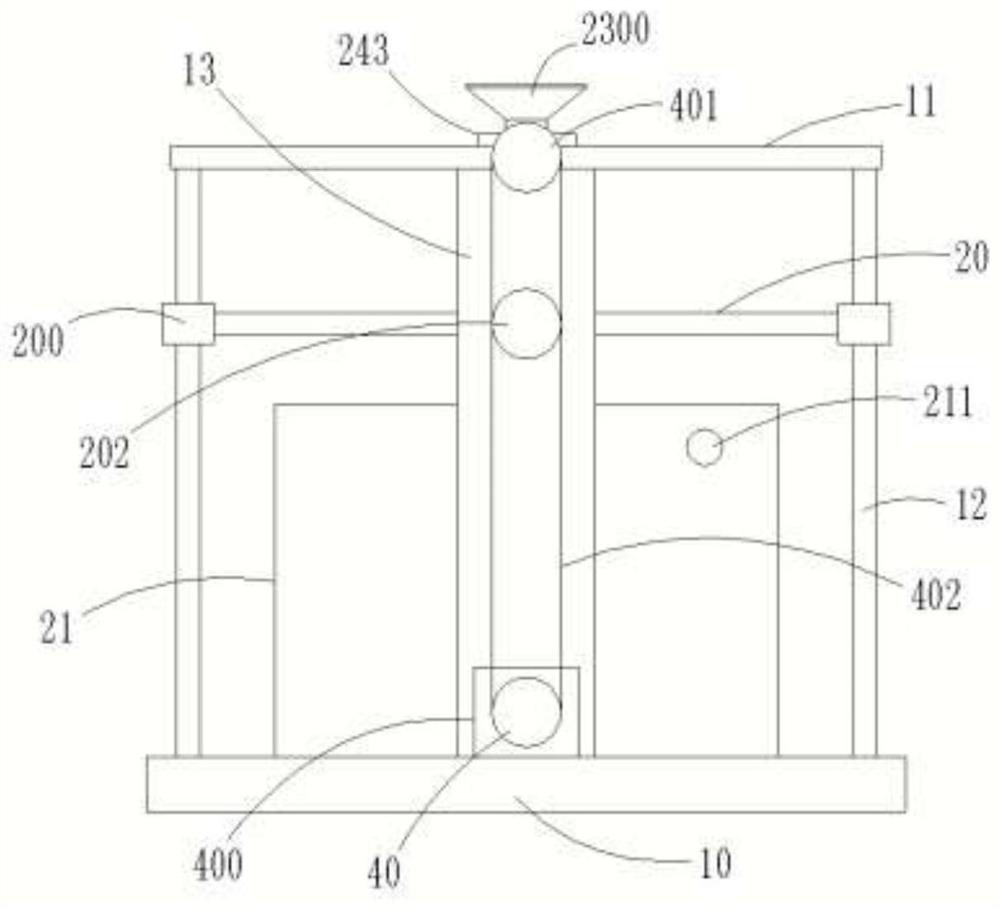

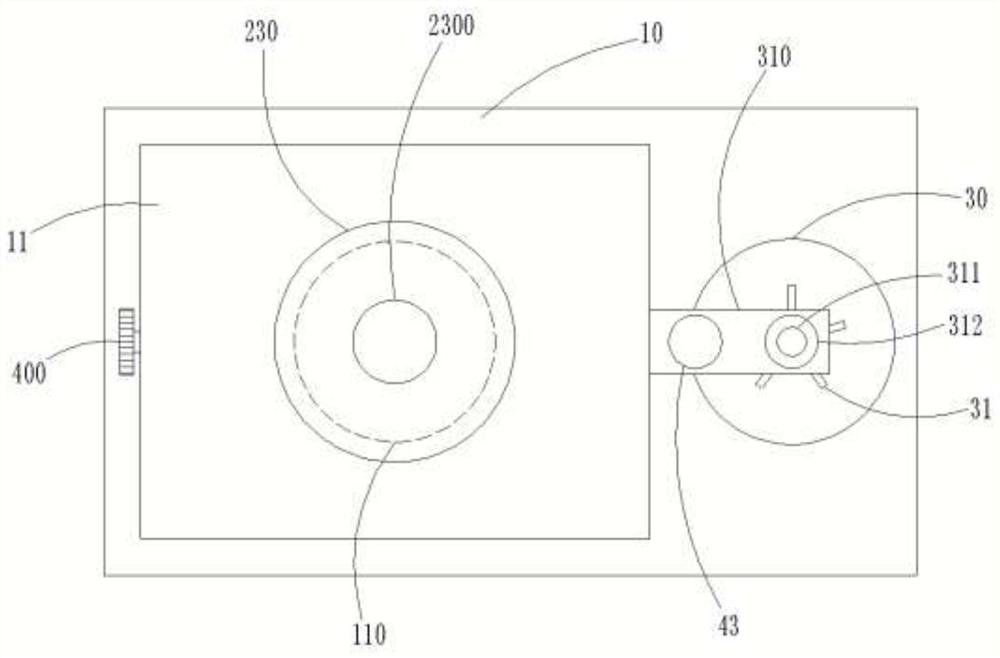

Method used

Image

Examples

experiment example

[0036] Experimental example: The phosphorus in the remaining sludge incineration ash after treatment in a domestic sewage treatment plant in northern my country is leached by the device of the above embodiment. The content of phosphate in the liquid can reach more than 80%, which is beneficial to the recovery of phosphorus; when MAP is used to recover the phosphorus in the supernatant, the recovery rate of phosphorus can be as high as 94.22%; it can be seen that the present invention can effectively extract the phosphorus Phosphorus in the ashes of sludge incineration, thus realizing the resource recycling of sludge solid waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com