Multi-degree-of-freedom suction arm support and dredging vehicle

A degree of freedom and boom technology, applied in waterway systems, cleaning sewer pipes, water supply devices, etc., can solve the problems of effectively controlling multiple angles of the suction pipeline, low work efficiency, and high labor costs, and achieves improved automation. The effect of reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

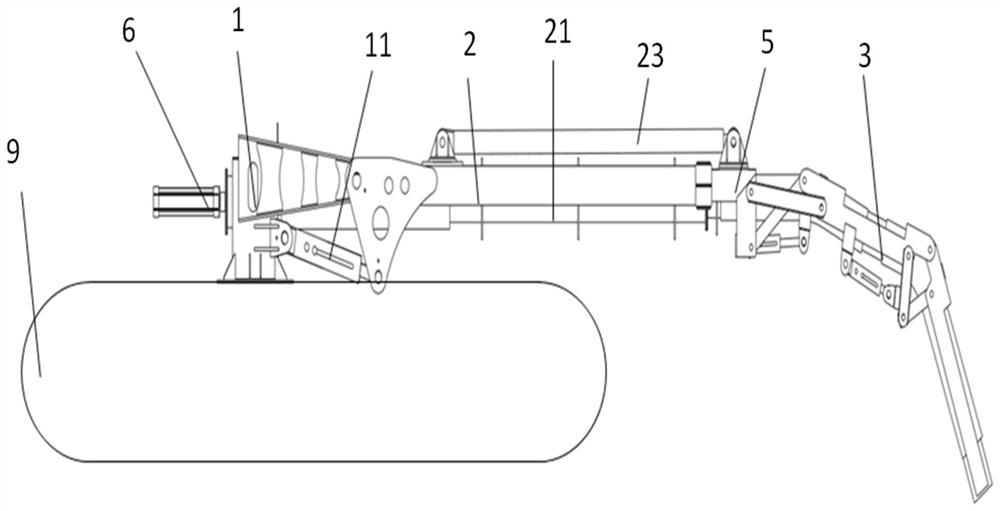

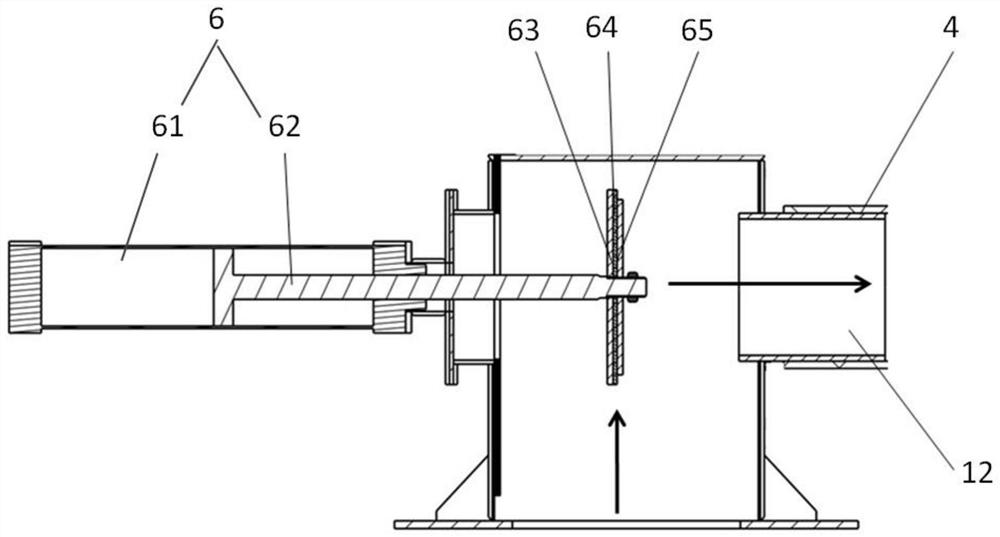

[0041] The invention provides a multi-degree-of-freedom suction boom, please refer to figure 1 , including a rotary mechanism 1, a lifting mechanism 2, a luffing mechanism 3, a suction hose 4 and a sliding mechanism 5, the rotary mechanism 1 is arranged at the material inlet of the tank body 9, the lifting mechanism 2 and the rotary Mechanism 1 is in transmission connection, the sliding mechanism 5 is in transmission connection with the lifting mechanism 2, the luffing mechanism 3 is in transmission connection with the sliding mechanism 2, and the discharge port 12 of the slewing mechanism 1 is connected with an overflow-proof sealing mechanism 6 , the slewing mechanism 1 is connected with the lifting mechanism 2 through the suction hose 4, the lifting mechanism 2 is connected with the sliding mechanism 5 through the suction inner and outer tubes, and the sliding mechanism 5 and the luffing mechanism 3 are connected through the suction Suction hose 4 connections.

[0042] Speci...

Embodiment approach

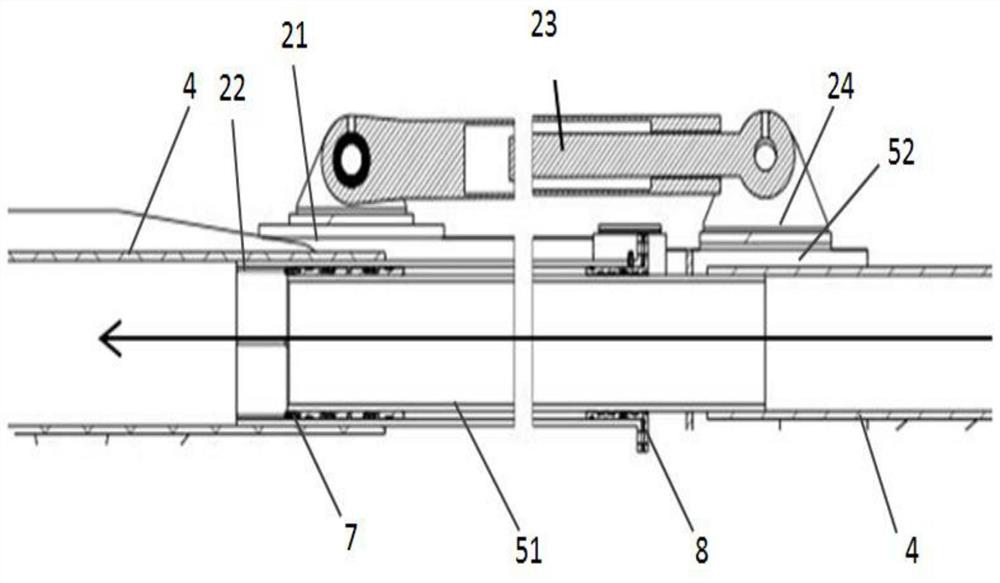

[0050] The first sealing mechanism 7 is arranged between the suction outer pipe 22 and the suction inner pipe 51, and the first sealing mechanism 7 is arranged at one end close to the rotary mechanism 1 to make the suction outer pipe 22 and the suction The inner tube 51 is gap-connected. As a preferred embodiment, the first sealing mechanism 7 includes a first guiding dirt-receiving ring 71, a piston seal 73, a V-shaped combined seal 74 and a slider 72, please refer to Figure 5 . Specifically, the first guide dirt-receiving ring 71, piston seal 73, V-shaped combined seal 74 plug and slider 72 are sequentially sleeved on the suction inner tube 51, and the slider 72 is located near the rotary mechanism 1. One end, in this embodiment, the slider 72 is a nylon slider, and the nylon slider acts as a guide. Institution 2 is connected.

[0051] The second sealing mechanism 8 is arranged between the suction outer tube 22 and the suction inner tube 51 to make the gap connection bet...

Embodiment 2

[0056] The present invention also provides a dredging vehicle, which adopts the multi-degree-of-freedom suction boom described in the first embodiment.

[0057] In this embodiment, the multi-degree-of-freedom suction arm is erected on the frame of the dredging vehicle. When the suction operation is required, the rotary mechanism 1 can rotate to different angles relative to the tank body 9, so that the third section The rear end of the arm 313 is used to extend to the sewer for suction work, and the media such as sludge, accumulated sand and stone, and consolidated waste are sucked to the lifting mechanism 2, the sliding mechanism 5, the turning mechanism 1 and the tank in sequence. 9 inside the body.

[0058] The lifting mechanism 2, the sliding mechanism 5, and the multi-degree-of-freedom luffing mechanism 3 are sealed and connected, and through the first luffing cylinder 32, the second luffing cylinder 11, and the telescopic oil cylinder 23, multiple degrees of freedom and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com