Electronic Waste Recycled Exhaust Processor

A technology for tail gas treatment and electronic waste, applied in gas treatment, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

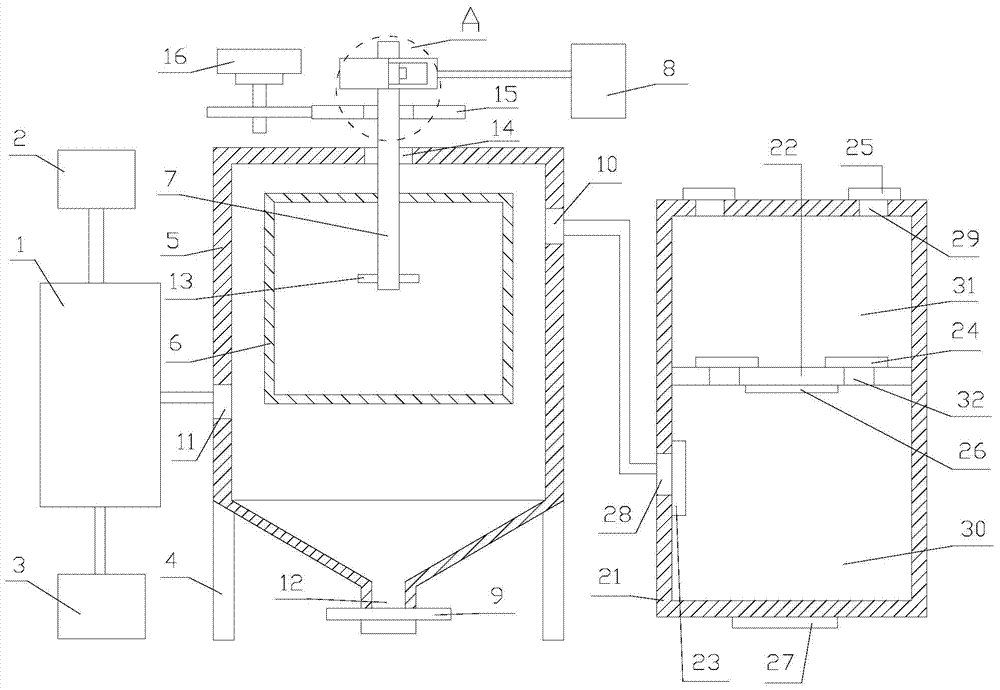

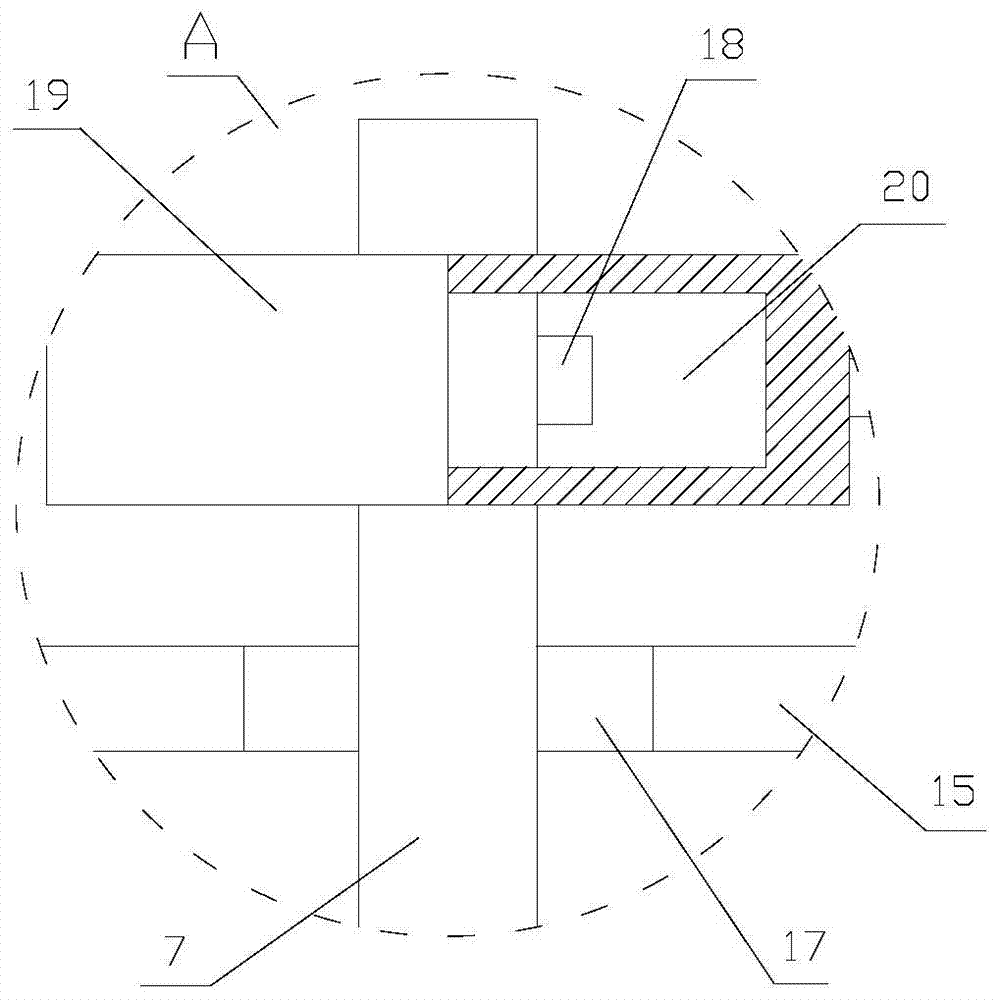

[0026] refer to figure 1 , 2 :

[0027] The present invention proposes a regenerated tail gas processor for electronic waste, comprising a semi-dry adsorption tower 1, a lime slurry preparation system 2, an activated carbon injection system 3, a dust collector, a suction mechanism, a lime slurry preparation system 2, an activated carbon injection system 3 and The semi-dry adsorption tower 1 is connected; the lime slurry sprayed by the lime slurry preparation system 2 is sprayed into the semi-dry adsorption tower 1, and the high-temperature gas of the semi-dry adsorption tower 1 is fully mixed with the injected lime slurry in a reverse flow , react with lime slurry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com