A single-row and double-row two-dimensional time grating linear displacement sensor

A linear displacement, double-row technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve the problems of difficult manufacturing, multi-layered, complex sensor structure, etc., to reduce the number of layers and the complexity of winding , Eliminate the influence of high-order harmonics, and simplify the structure of the sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the drawings.

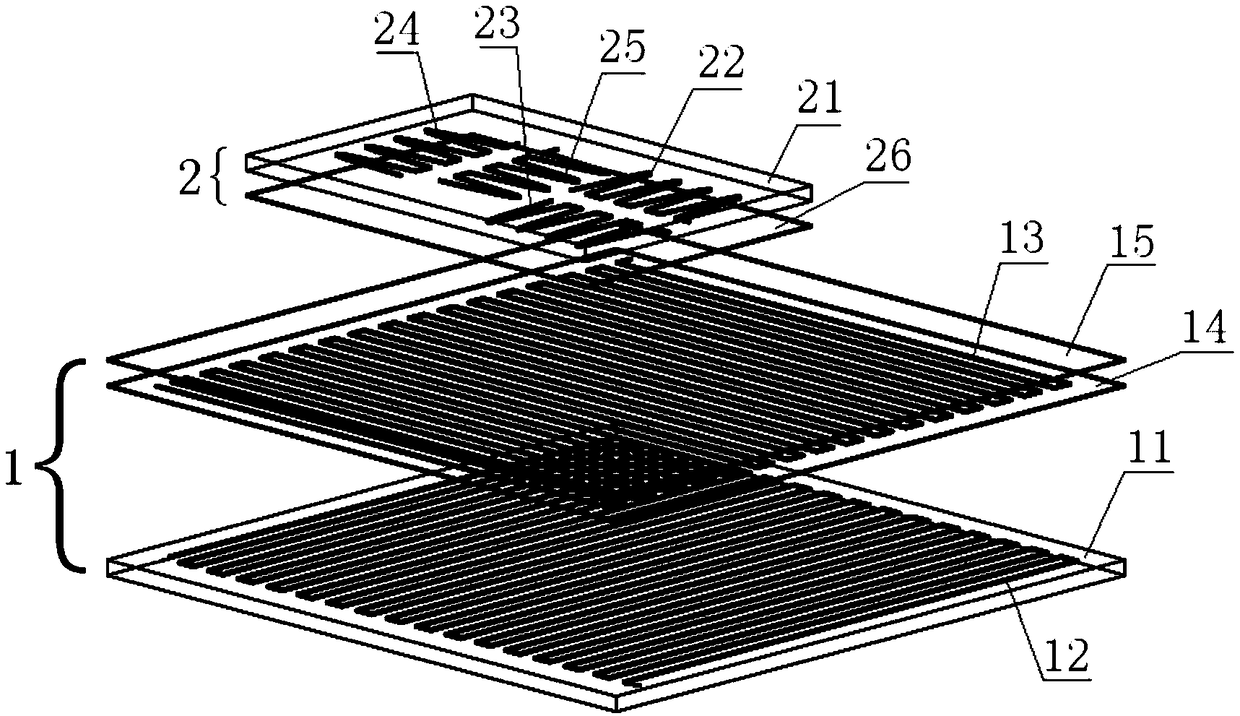

[0019] Such as Figure 1 to Figure 5 The single-row and double-row two-dimensional time-grid linear displacement sensor shown includes a fixed length 1 and a movable ruler 2 that is parallel to the fixed length 1 and has a gap of 0.2 mm.

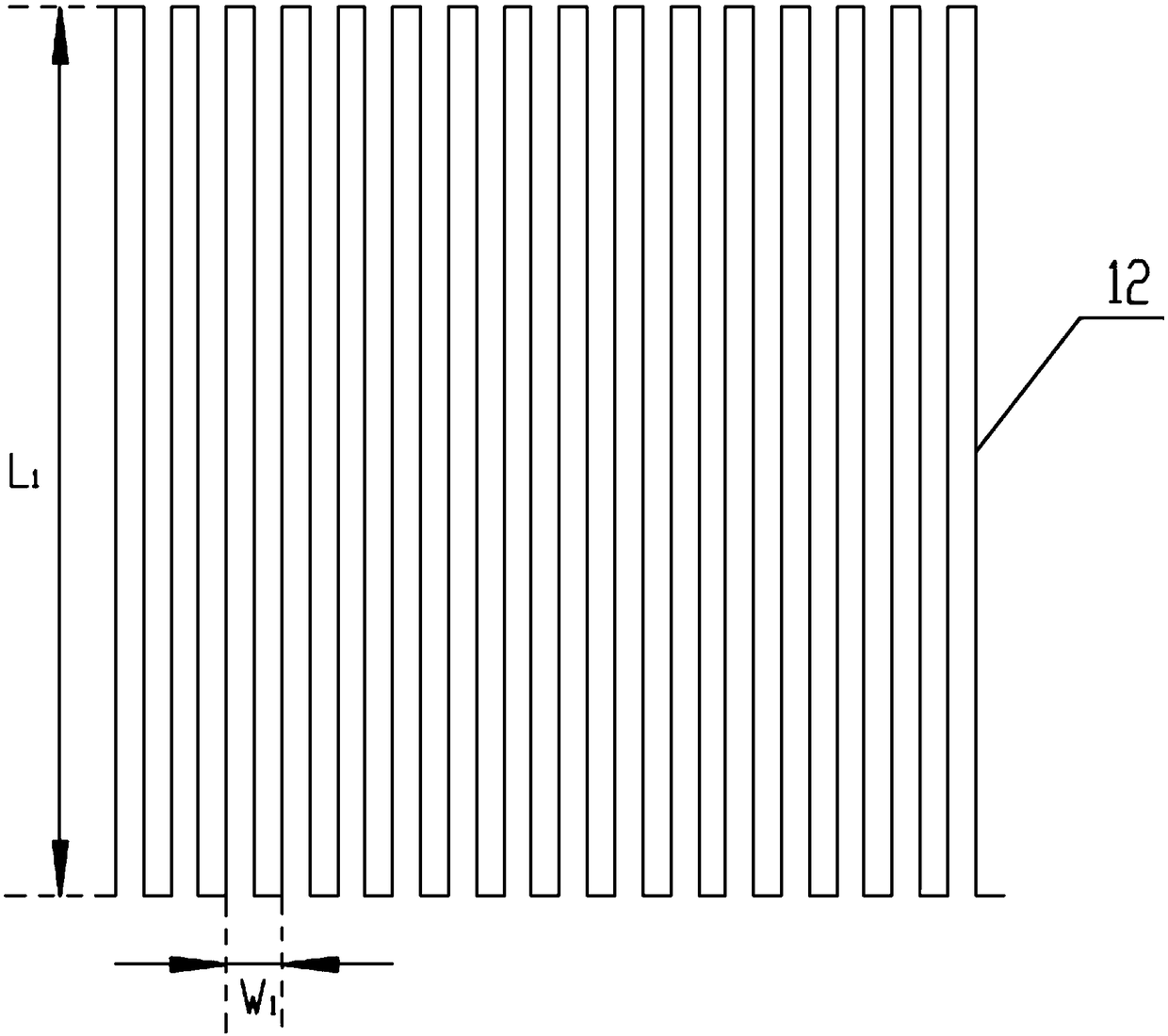

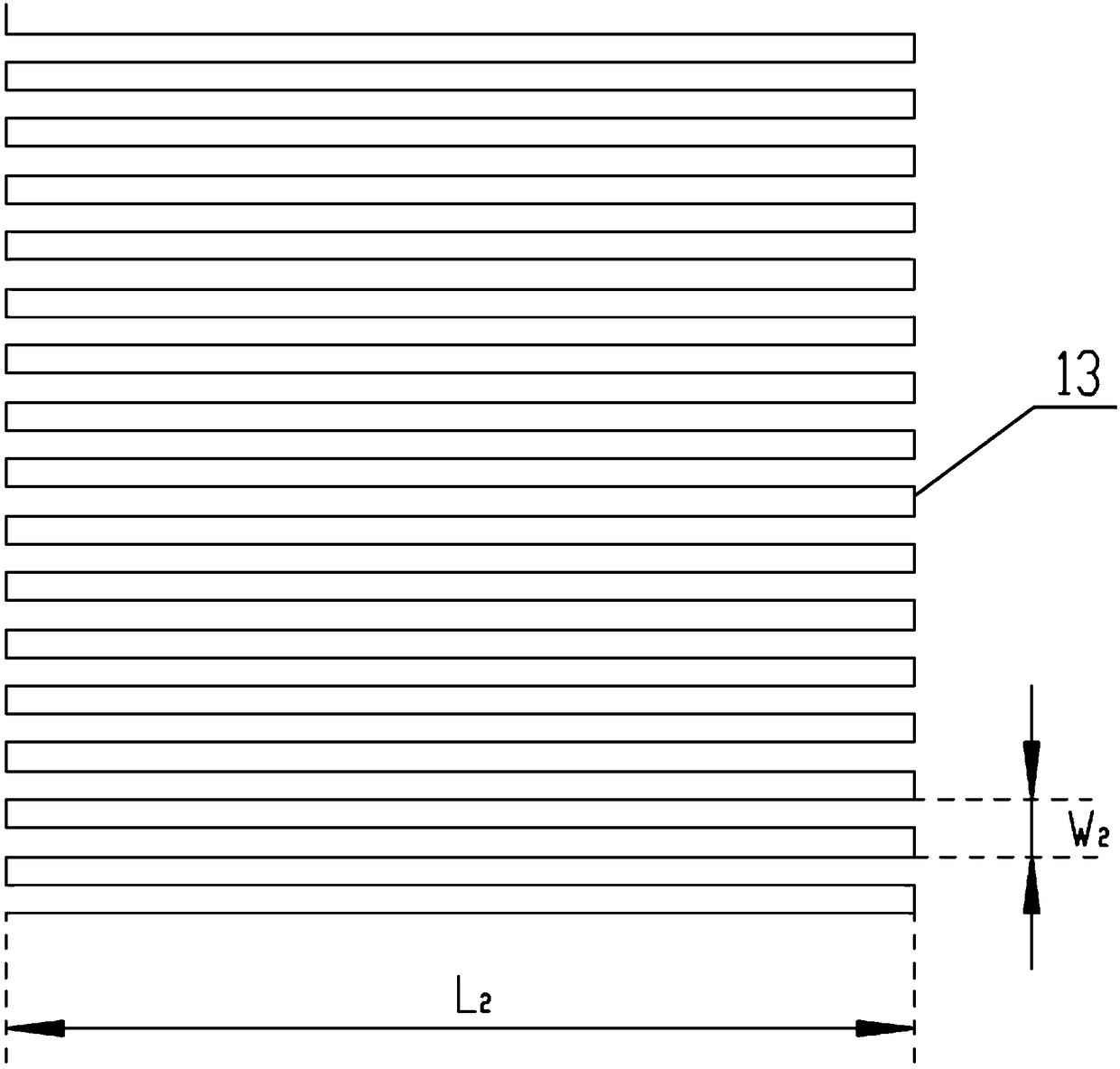

[0020] The fixed-length 1 includes a fixed-length base 11, a first excitation coil 12 arranged in a first wiring layer on the side of the fixed-length base 11 facing the movable ruler, a second wiring layer 14 arranged on the first wiring layer, and The second excitation coil 13 in the second wiring layer 14 and the fixed-length insulating layer 15 provided on the second wiring layer 14, the first excitation coil 12 and the second excitation coil 13 are insulated from each other and do not interfere with each other. The projection of the ruler base 11 can completely cover the first and second excitation coils. The fixed-length base 11 is a non-magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com