Sorting system applied to second-level and third-level parcel sorting processing centers

A sorting system and package technology, applied in sorting and other directions, can solve the problems of inability to fully realize intelligent sorting, limited number of manual sorting compartments, increase labor and material costs, etc., to save labor and material costs, and achieve good sliding effect. , The effect of stable sorting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

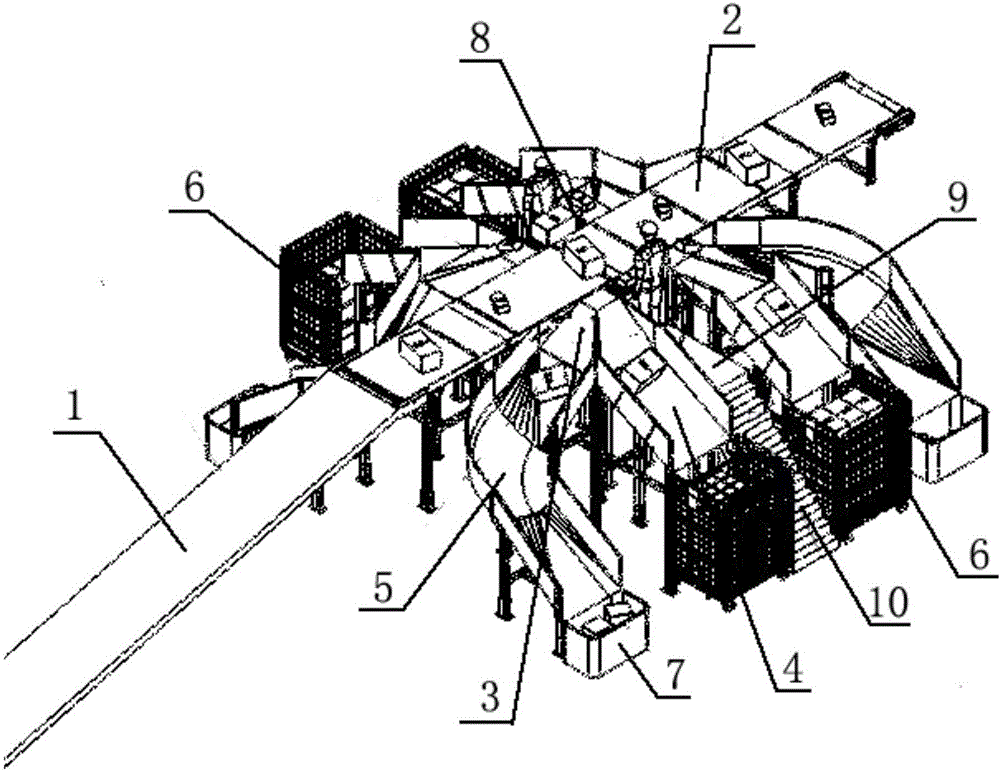

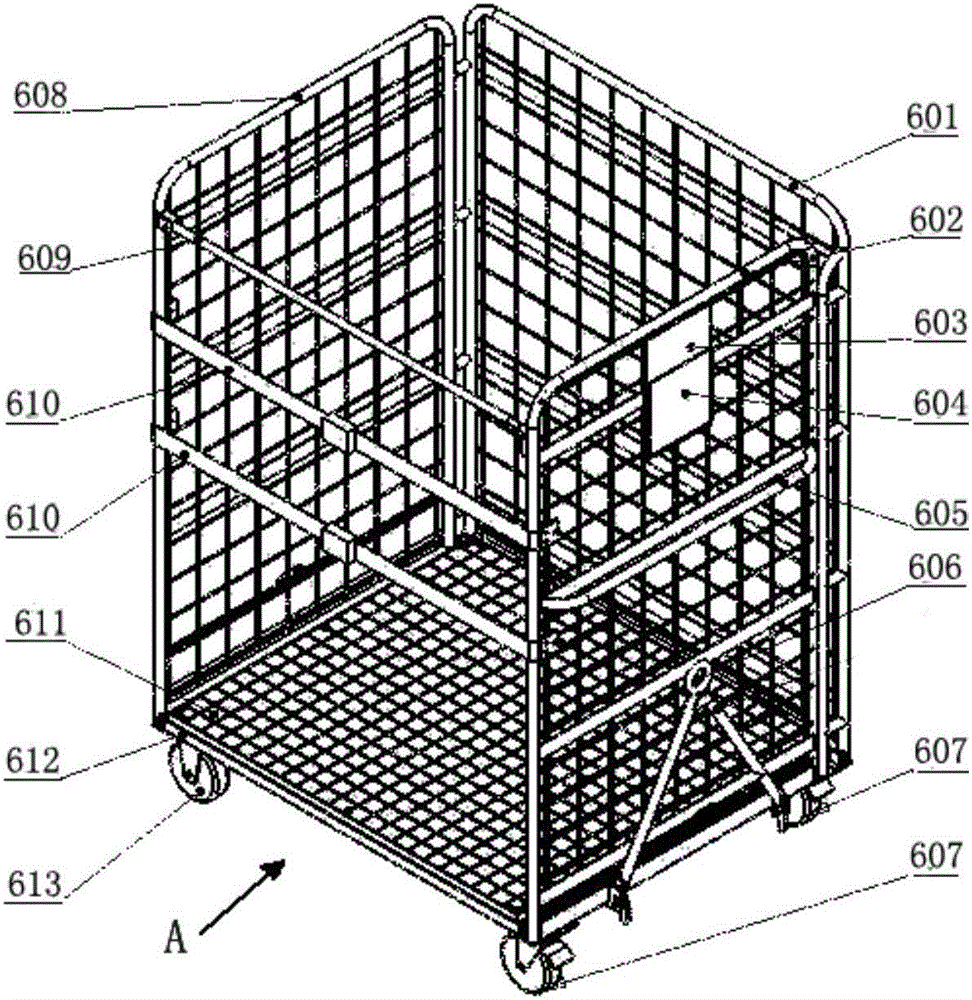

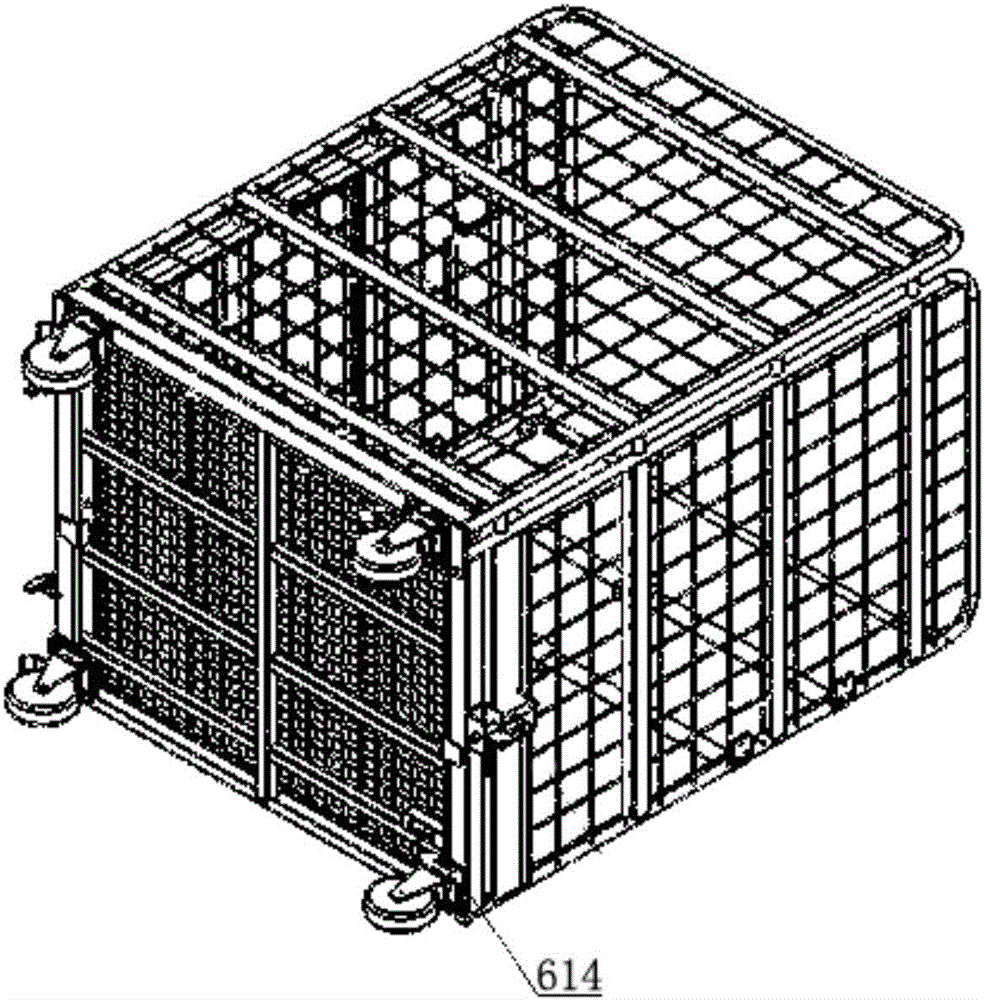

[0030] like figure 1 As shown, the present invention provides a kind of sorting system applicable to the second and third grade parcel sorting processing centers, which includes climbing belt conveyor 1, linear belt conveyor 2, matrix chute, bullseye table 8, for The cage car 6 loaded with sorted packages of the same kind and the mail bag rack 7 for placing and supporting bulk mail bags.

[0031] The linear belt conveyor 2 is connected with the climbing belt conveyor 1, and the two belt conveyors are used to realize the transportation of the parcels and make them enter the sorting link. There are at least four matrix chutes, and they are evenly distributed on both sides of the linear belt conveyor. After the matrix chutes are used for parcel sorting, they are classified into the mailbags of the cage car 6 or the mailbag rack 7 . In the present embodiment, the matrix chute includes a chute inlet 3, a dividing plate arranged in the chute inlet 3 and divided into two inlets, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com