Friction cleaning machine

A friction cleaning machine and component technology, applied in cleaning methods and utensils, solid separation, filter screens, etc., can solve problems such as poor cleaning effect, insufficient power, material expansion, etc., to achieve good cleaning effect, sufficient power, and easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

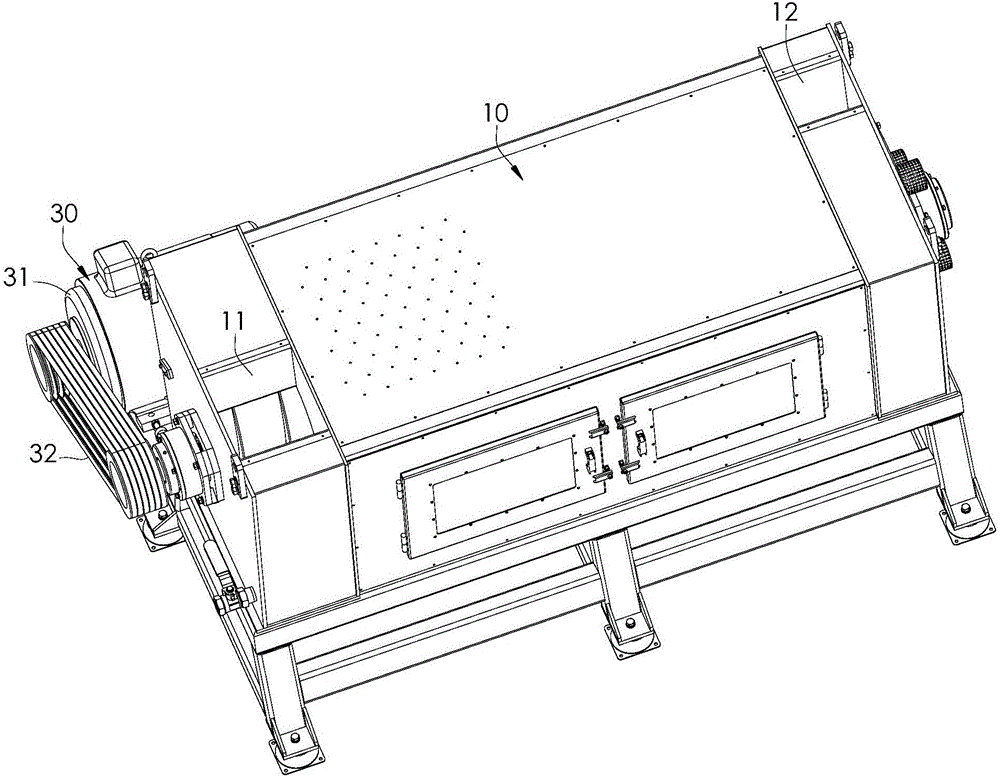

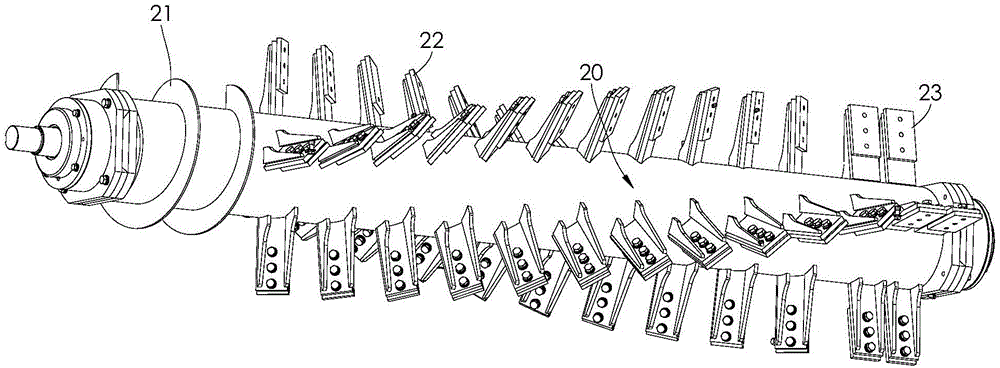

[0023] Such as figure 1 and figure 2 As shown, the friction cleaning machine of the present invention includes a box body 10 and a rotating shaft 20 . A cleaning space is formed inside the box body 10, and a screen is installed on the inside of the cavity. The box body 10 is provided with a feed port 11 and a discharge port 12 communicating with the cleaning space; the rotating shaft 20 is pivotally connected to the box body 10 And be located in this cleaning space; The outer surface of rotating shaft 20 is respectively provided with a continuous helical blade 21, inclined blade 22 assembly and straight blade 23 assembly, and this helical blade 21, inclined blade 22 assembly and straight blade 23 assembly are along the axis of rotating shaft 20 Arranged in sequence; the helical blade 21 extends along the first helical line, the helical blade 21 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com