Correction mold for automobile rear axle housing

An automotive rear axle and mold technology, applied in forming tools, manufacturing tools, vehicle parts, etc., can solve problems such as damage to the rear axle housing, and achieve the effects of preventing damage, improving the clamping process, and correcting efficiency quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

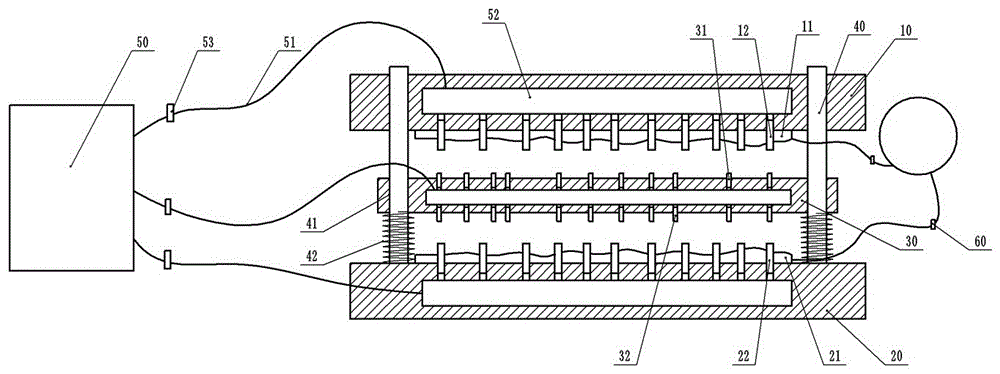

[0015] The reference signs in the accompanying drawings of the description include: upper die base 10, upper air cushion 11, upper correction block 12, lower die base 20, lower air cushion 21, lower correction block 22, middle plate 30, upper positioning block 31, lower positioning block 32. Guide post 40, guide hole 41, spring 42, hydraulic station 50, high pressure pipe 51, cavity 52, control valve 53, inflation valve 60.

[0016] Such as figure 1 As shown, the automotive rear axle housing correction mold includes an upper mold base 10, a lower mold base 20 and an intermediate plate 30. Four guide columns 40 are fixed on the lower mold base 20, and the positions of the four guide columns 40 form a rectangle. Guide holes 41 are provided on the positions of the middle plate 30 and the upper mold base 10 that are matched with the four guide posts 40 . The lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com