Tool for processing tubular positive plate grating

A positive plate and tooling technology is applied in the field of processing equipment for tubular positive grids, which can solve the problems of affecting the processing progress, inconvenient insertion, folded or broken lead bars, etc., so as to improve production efficiency and reduce scrap rate. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

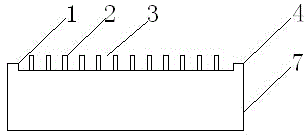

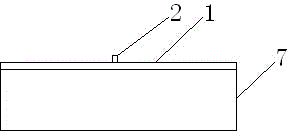

[0012] The present invention is described in further detail in conjunction with accompanying drawing, and the present invention comprises base 7, and a row of separating columns 2 is arranged at equal intervals in the middle of base 7, and the gap 3 between separating columns 2 is less than the internal diameter of the pipe hole on the row pipe, greater than that of the lead bar. Diameter, the separating column 2 is made into a cylinder.

[0013] In a further preferred embodiment, in order to further improve the production efficiency, a groove is provided on the base 7, and the separation column 2 is arranged at the bottom of the groove and between the walls 1, 4 of the groove.

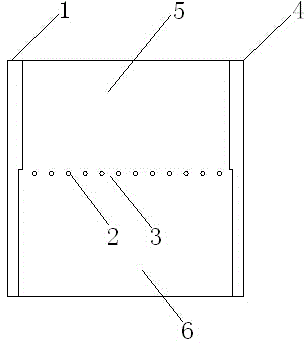

[0014] Further preferred embodiments, such as image 3 As shown, the width of the groove 5 on one side of the separation column is equal to the width of the grid, and the width of the groove 6 on the other side of the separation column is equal to the width of the row of pipes. The grid and row of pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com