Log wave splicing plate and splicing method

A technology of splicing boards and waves, which is applied to the jointing of wooden veneers, chemical instruments and methods, and wood layered products, can solve the problems of waste of cost, non-environmental protection, etc., and achieve cost reduction, simple structure, and convenient splicing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

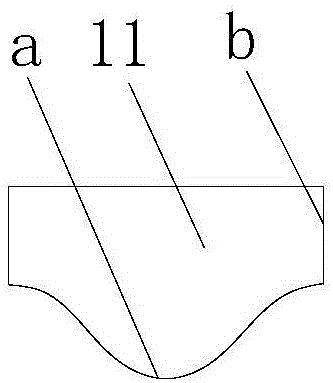

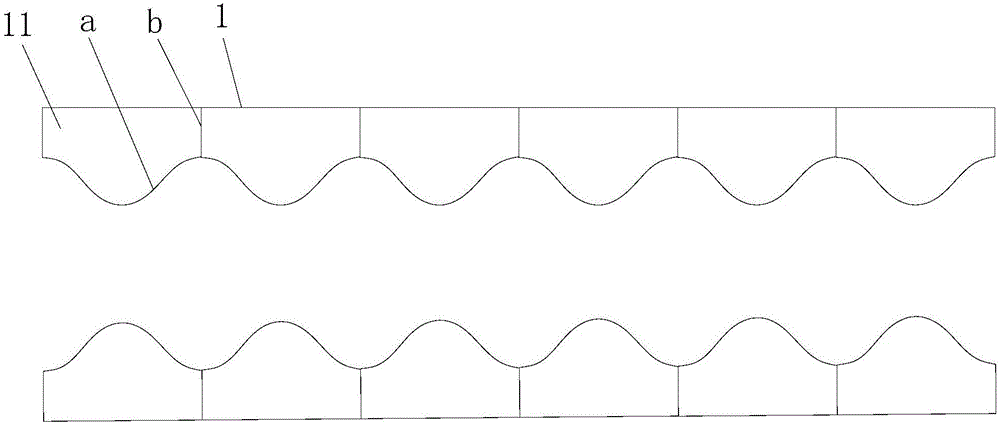

[0021] Please refer to Figure 1-4 , the log wave splicing board is composed of two wave-shaped boards 1 seamlessly spliced on the side of the wave-shaped surface a, each wave-shaped board 1 is composed of a plurality of wave-shaped logs 11, and each wave-shaped log 11 is formed in a wave-shaped The adjacent side of the surface a is a straight surface b, and a plurality of wave-shaped logs 11 are pasted and assembled on the flat surface b to form the wave-shaped board 1 . Specifically, one side of each of the wave-shaped logs 11 is a wave-shaped surface a, and the other three sides are straight surfaces b, and the wave shape of the wave-shaped surface a of each wave-shaped log 11 is composed of a wave crest and a wave shape located on both sides of the wave crest. The two half-troughs of . The flat surfaces b of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com