Five-layer co-extrusion machine

A technology of extruder and frame, applied in the field of five-layer co-extrusion machine, can solve the problems of inconvenient maintenance and clutter, and achieve the effect of saving space, convenient adjustment and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

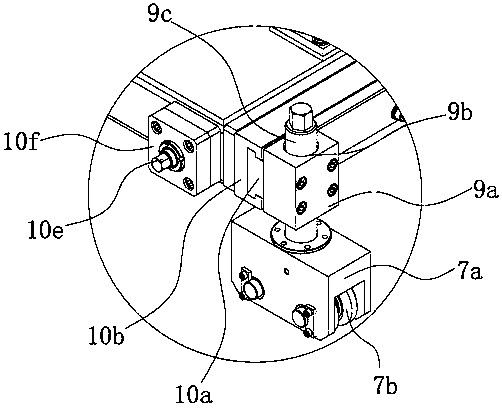

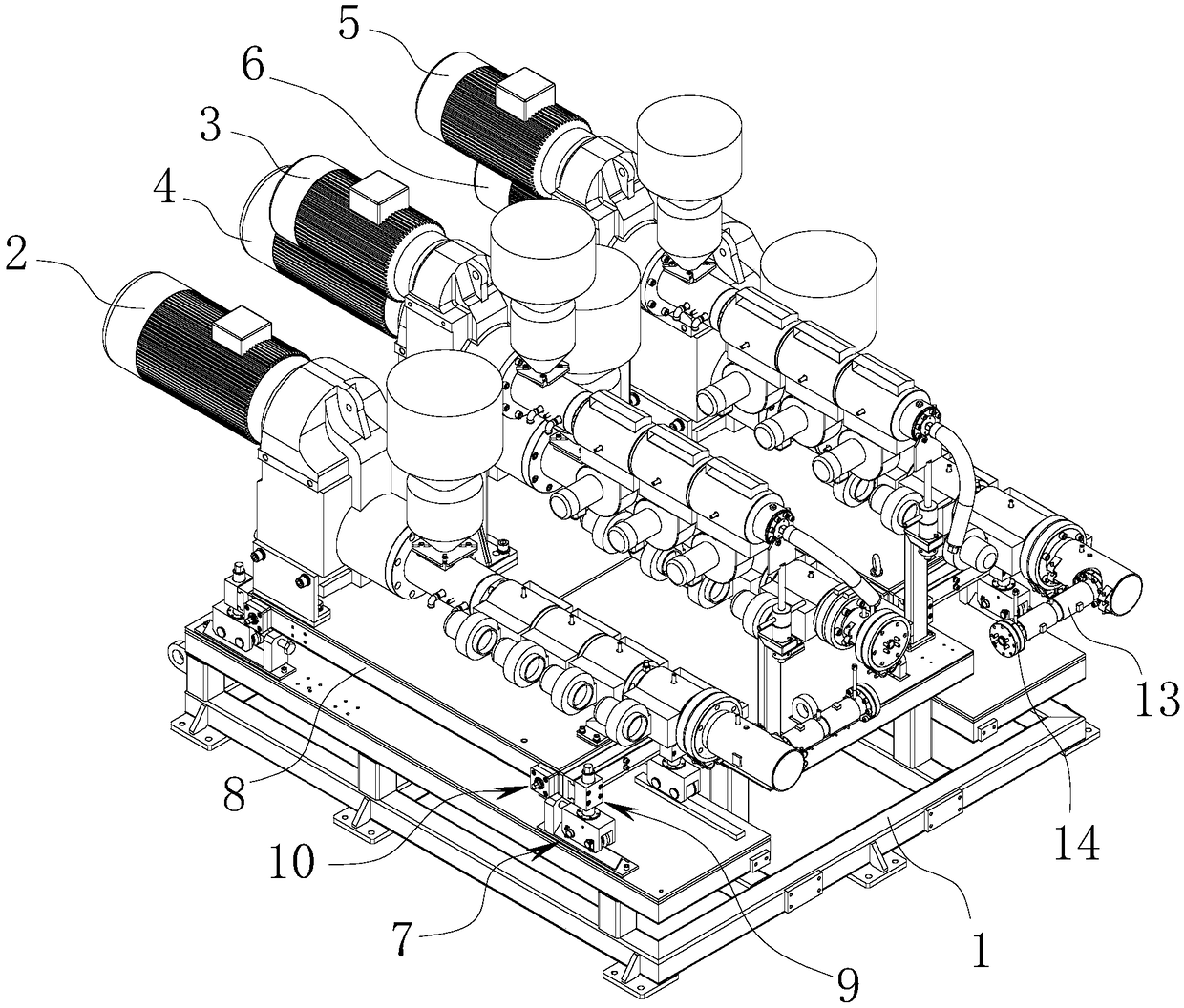

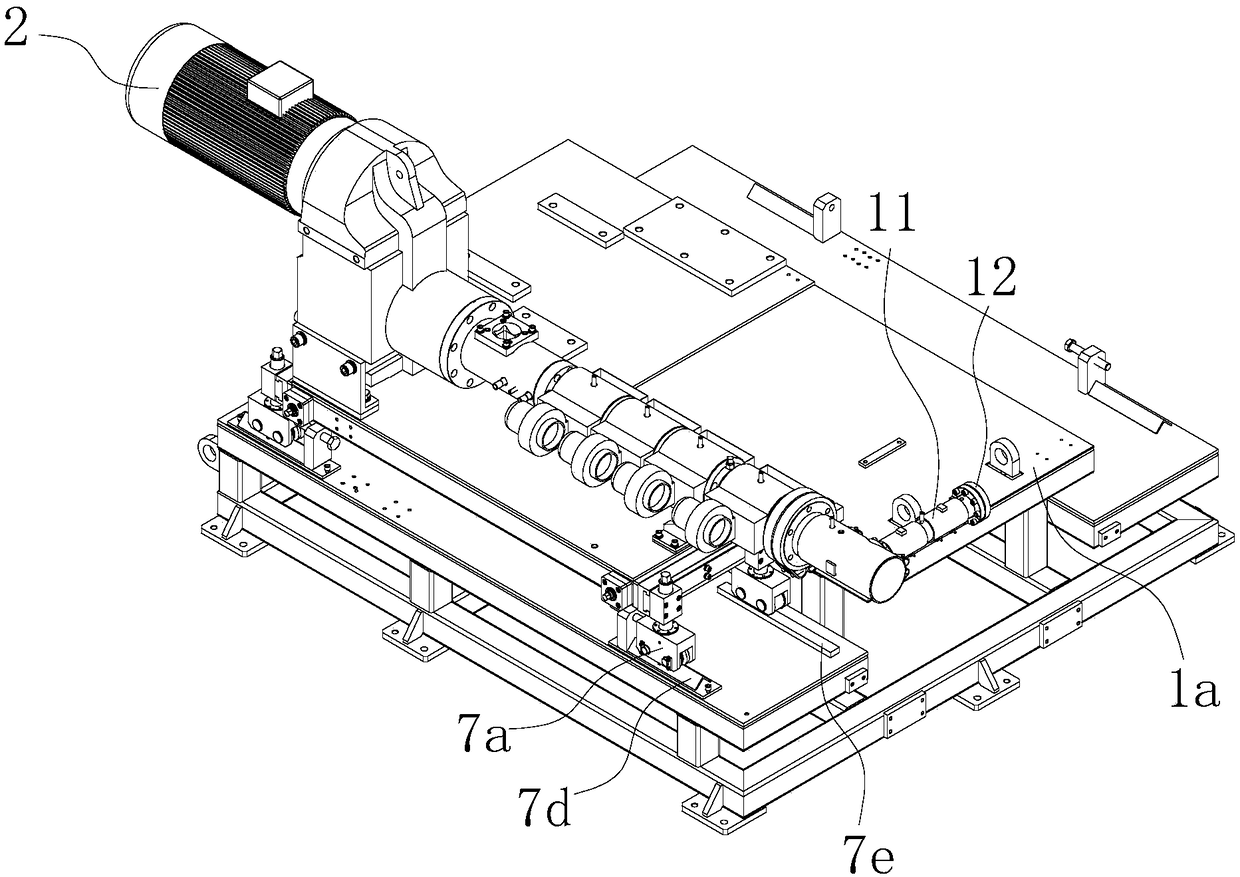

[0025] refer to Figure 1 to Figure 9 As shown, a five-layer co-extrusion machine of the present invention includes a frame 1, on which a nylon outer layer extruder 2 and a first glue layer extruder 3 are sequentially arranged along the length direction of the frame 1 , Nylon inner layer extruder 4, second glue layer extruder 5 and middle layer extruder 6. Frame 1 is provided with 5 barrel supporting feet opposite to the end of each extruder, and the barrel supporting feet can effectively prevent the barrel from being deformed due to long-term suspension. In this embodiment, the nylon outer layer extruder 2, the first glue layer extruder 3, the nylon inner layer extruder 4, the second glue layer extruder 5 and the middle layer extruder 6 all adopt screw extrusion machine. Preferably, the frame 1 is composed of an upper installation platform 1a, a lower installation platform 1b arranged on both sides of the upper installation platform 1a, and an installation frame arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com