Optimizing method for transmission mechanism of toggle rod servo press

A technology of servo press and optimization method, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of high equipment cost, unfavorable promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

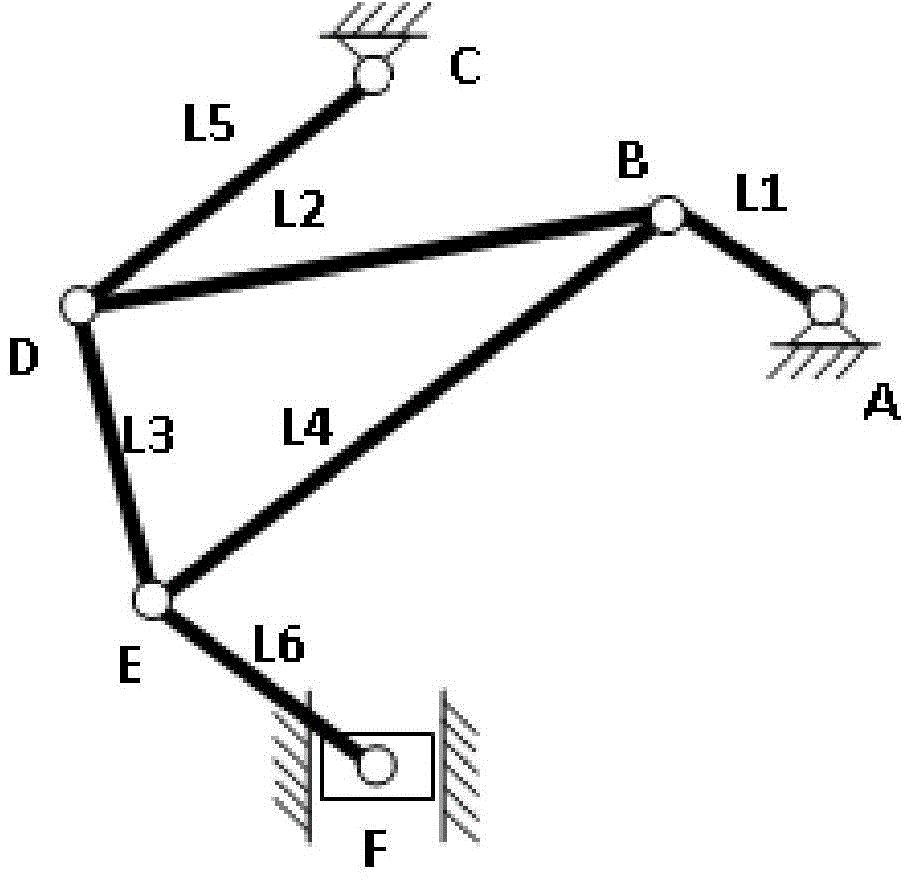

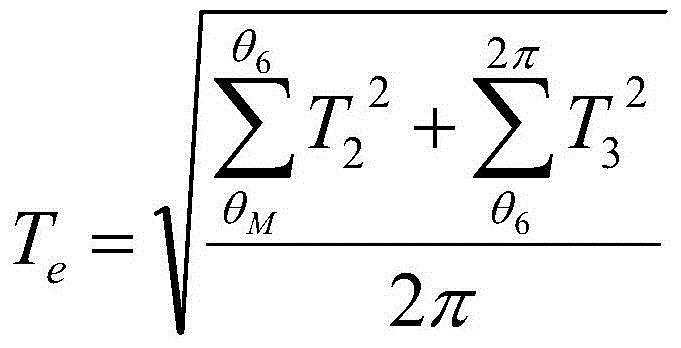

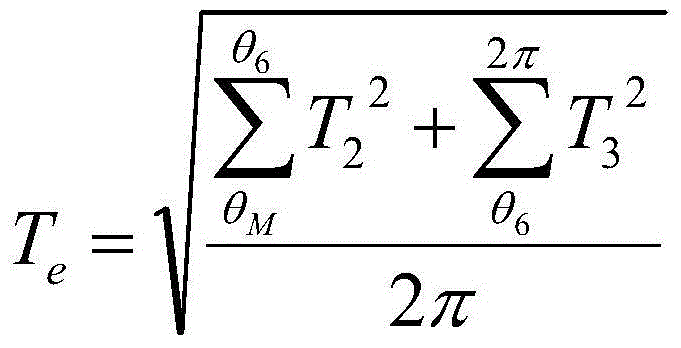

[0015] A method for optimizing the transmission mechanism of a toggle servo press, the toggle servo press includes a servo motor, a frame, an upper link, a lower link, a crank, a triangular rod and a slider, and the servo motor drives an output shaft One end of the crank is connected, the other end of the crank is connected with one apex of the triangular rod, the other two vertices of the triangular rod are respectively connected with the lower end of the upper link and the upper end of the lower link, and the upper end of the upper link is connected with the frame , the lower end of the lower connecting rod is connected with the slider. Among the triangular rods, the rod connecting the crank and the upper connecting rod is used as the upper rod, and the rod connecting the crank and the lower connecting rod is used as the lower rod to connect the upper and lower rods. The rod of the lower connecting rod is the bottom rod, and the lengths of the crank, upper rod, lower rod, bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com